1. Connecting solar tubes and copper wires requires specific steps and considerations: a. Understanding the compatibility of materials is essential, b. Selecting appropriate tools significantly impacts the connection quality, c. Following safety protocols ensures a secure connection, d. Properly managing cable lengths and routes is crucial for efficiency.

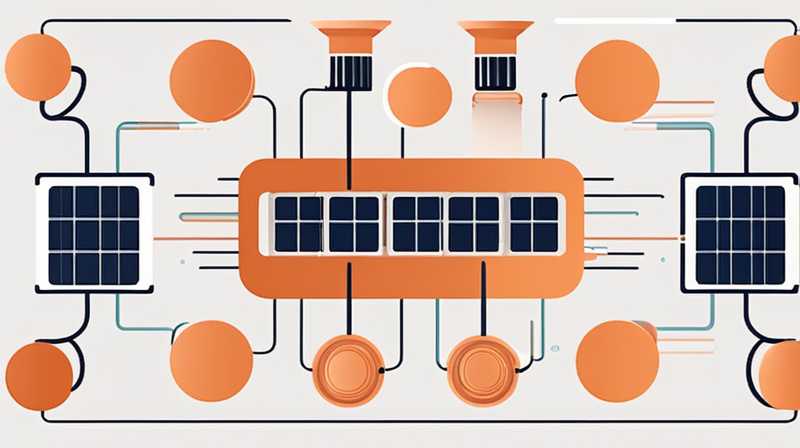

To delve deeper into the connections between solar tubes, which enhance natural lighting, and copper wires that conduct electricity, an awareness of the chemistry and physics behind these elements becomes necessary. While solar tubes operate to harness sunlight and channel it into different parts of a building, copper wires serve to transmit energy from solar panels to storage units or electrical grids. Each component must work seamlessly to maximize efficiency and functionality.

1. MATERIAL COMPATIBILITY

Understanding the compatibility of materials is crucial. When combining solar tubes with copper wires, one must ensure that both components can function together without any adverse reactions. Solar tubes are primarily made of durable materials like glass or polycarbonate. In contrast, copper wires are a common choice for electrical connections due to their excellent conductivity.

Potential issues can arise when the materials are not compatible. For instance, if the copper wire is exposed to moisture over prolonged periods, it might corrode, which could lead to a significant decrement in connectivity efficiency. Moreover, the choice of solder or connectors used in this coupling can also impact effectiveness. For example, utilizing non-corrosive, high-grade connectors prevents degradation over time, ensuring that the energy transferred through the connection remains efficient.

Employing corrosion-resistant materials can significantly bolster the lifespan and performance of the connection. Types of connectors or solder that can withstand environmental stress should always be considered. Moreover, ensuring proper sealing where the solar tubes interface with copper wires can prevent moisture ingress, thus optimizing functionality and safety.

2. SELECTING TOOLS

Selecting appropriate tools significantly impacts the connection quality. The right tools can facilitate a smoother process and ensure a secure, effective connection. For the job at hand, tools like wire strippers, soldering irons, heat shrink tubing, and multimeters are essential for achieving a reliable link between solar tubes and copper wires.

Wire strippers play a pivotal role when connecting copper wires to ensure that the insulation is removed without damaging the wire itself. Once the wire is stripped, soldering irons can be employed to create a strong bond between the wire and the connector or terminal. Utilizing heat shrink tubing provides a protective layer after the solder joint has cooled, thus safeguarding against environmental factors.

Additionally, using a multimeter can verify the connection’s integrity once established. This device helps ensure that the flow of electricity is as expected, and no short circuits or breaks in connectivity exist. Proper use of each tool will enhance not just the immediacy of the connection, but also the longevity and reliability, in turn, maximizing the efficiency of the solar energy system as a whole.

3. SAFETY PROTOCOLS

Following safety protocols ensures a secure connection. Prioritizing safety is paramount when working with electrical components, particularly when they are integrated with renewable energy solutions such as solar tubes. The potential for working with live wires necessitates a structured approach to personal and environmental safety.

Wearing personal protective equipment (PPE) like gloves and safety goggles can significantly mitigate risks. Beyond personal safety, ensuring that work areas are well-lit and free from unnecessary clutter can enhance focus and prevent accidents. Before commencing any connection work, it is crucial to turn off power supplying components to avoid the risk of electric shock.

Furthermore, it is advisable to utilize tools that have insulated handles, providing an additional layer of safety while conducting electrical work. Regular checks on tools and equipment for wear or damage can further minimize potential hazards. Implementing comprehensive safety protocols is not just about individual precaution; fostering a secure environment promotes overall project success.

4. CABLE MANAGEMENT

Properly managing cable lengths and routes is crucial for efficiency. Effective cable management reduces wear and tear on the copper wiring and can prevent signal loss. Copper wires, due to their conductive nature, need to be laid out in a manner that minimizes interference and exposure to environmental factors.

Prior planning of cable routes should consider distances, bends, and obstacles that could affect the path of electricity flow. Long stretches of wire can lead to voltage drop, which may hinder the overall performance of the system. Through careful calculation of wire lengths, while also taking into account necessary slack for movement, one can ensure a more effective installation.

Additionally, organizing cables using ties or conduits keeps everything tidy and prevents tangling. Ensuring cables are secured will also prevent potential safety hazards, such as tripping. In the end, maintaining a keen eye on cable management contributes to a smoother operation and longevity of the solar energy system.

5. PERFORMING THE CONNECTION

Executing the actual connection process will require patience and attention to detail. When ready to link the solar tubes with copper wires, initiate by ensuring that all necessary tools and components are readily available and organized. Start by preparing the wires, precisely stripping the ends as previously discussed.

Once the wires are prepped, make the connection by soldering or using appropriate connectors. Ensure that heat is evenly distributed during the soldering process, avoiding overheating or underheating, which may lead to a weak bond. After soldering, let the connection cool, and cover exposed areas with heat shrink tubing, sealing them adequately to prevent moisture ingress.

Utilizing a multimeter post-connection will confirm the integrity and efficiency of the link. Check the connection for continuity, verifying that electricity flows without hitch. Proper application of these methods will not just fulfill the connectivity needs but will also reinforce the entire solar energy setup.

FREQUENTLY ASKED QUESTIONS

WHAT ARE SOLAR TUBES?

Solar tubes, often known as tubular skylights or sun tubes, are efficient daylighting systems designed to channel natural light into buildings. They consist of a dome-shaped collector that sits on the roof and a reflective cylindrical tube that directs sunlight into the desired interior space. These systems can significantly minimize reliance on artificial lighting, lowering energy consumption. Solar tubes create a bright interior ambiance, and unlike traditional skylights, they do not require extensive structural changes. They are ideal for hallways, bathrooms, or any area lacking windows. Installation involves cutting a hole in the ceiling and affixing the components securely, ensuring minimal energy loss.

HOW DO COPPER WIRES FUNCTION IN SOLAR ENERGY SYSTEMS?

Copper wires play a crucial role in solar energy systems by serving as conductors of electricity generated by photovoltaic panels. Due to their excellent conductivity, copper wires enable efficient energy transfer from solar panels to inverters and storage batteries or directly to appliances. Properly sized copper wires ensure that the system can handle the currents produced by the solar panels without overheating or suffering from energy loss. It is essential to account for factors like wire gauge and length to prevent voltage drop and ensure the system operates effectively. Selecting high-quality copper wire and connectors further enhances the system’s performance over its lifespan.

WHAT ARE THE BENEFITS OF PROPER CABLE MANAGEMENT?

Proper cable management in solar energy installations offers a plethora of advantages. Firstly, it minimizes wear and tear on the cables, promoting durability and longevity, thus ensuring continuous electricity flow. Secondly, well-organized cables reduce the risk of tripping hazards, significantly enhancing workplace safety during installation and maintenance. Furthermore, managing cables efficiently decreases interference and enhances the overall performance of the energy system. By ensuring minimum bends and avoiding entanglement, cable management also provides easier access for troubleshooting or upgrades. The time and effort invested in proper cable management can translate to greater operational efficiency and reduced long-term costs.

The successful connection of solar tubes and copper wires is paramount for optimizing the efficiency of solar energy systems. Carefully considering material compatibility, tool selection, safety protocols, cable management, and the connection process itself greatly influences the effectiveness and longevity of the whole setup. An efficient approach to these aspects ensures a seamless flow of energy, maximizing harnessing from natural light while addressing crucial safety measures. Furthermore, the relationship between solar tubes and electrical systems extends beyond mere aesthetics, enabling significant contributions to energy savings, environmental sustainability, and overall enhancement of indoor living quality. A thorough understanding of these connections can empower individuals or organizations engaged in renewable energy practices. Such mastery positions one not just as a participant in the energy revolution but as a proactive contributor to a greener future. By continually evolving knowledge bases and improving techniques, it is entirely possible to anticipate future advancements in these sustainable technologies, ensuring readiness to adapt and benefit from emerging innovations. Therefore, a meticulous approach, coupled with a commitment to education and improvement, marks the journey towards achieving true energy independence.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-solar-tubes-and-copper-wires/