To connect a solar tube to a solenoid valve, it is essential to follow a systematic approach for optimal performance. 1. Identify the components involved, 2. Gather necessary tools, 3. Ensure proper safety measures, 4. Understand the connection methods, 5. Test the system post-connection. The process encompasses several steps that, if executed correctly, result in effective functionality of the solar energy system. Among these points, the understanding of connection methods warrants detailed attention, as this determines the efficiency and reliability of the system being installed.

1. UNDERSTANDING THE SOLAR TUBE AND SOLENOID VALVE CONNECTION

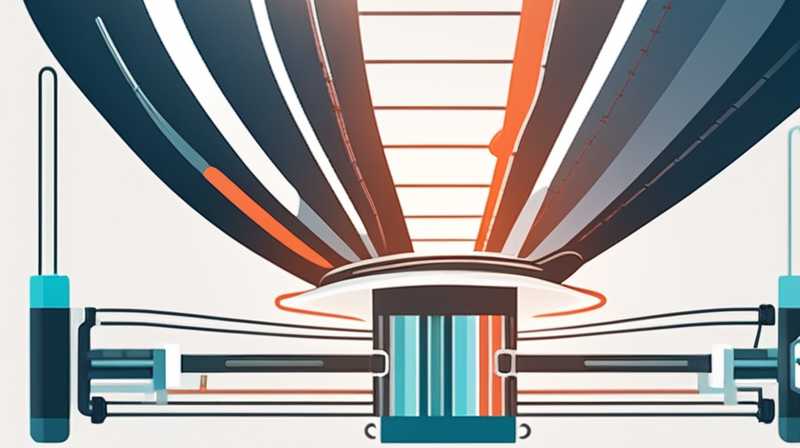

The integration of solar tubes and solenoid valves operates at the intersection of renewable energy technology and fluid dynamics. Solar tubes, also referred to as evacuated tube collectors, harness solar energy, converting it into heat. These devices are commonly utilized in residential and commercial heating applications. On the other hand, solenoid valves are electromechanical devices used to control fluid flow in various systems, functioning as a switch that enables and disables the flow when energized. Understanding the specific roles and functionalities of both components is vital before attempting a connection.

The synergy between a solar tube and a solenoid valve primarily hinges upon the effective transfer of energy. When combined, these systems can heat water or fluids for diverse applications, such as heating systems, irrigation setups, or even industrial processes. To ensure optimum performance post-installation, meticulous attention should be paid to each step of the connection procedure. It is not merely about connecting two components; it involves creating a cohesive unit that operates efficiently under various environmental conditions.

2. COMPONENTS AND TOOLS REQUIRED

Completing a successful connection requires the utilization of several components and tools. Among the essential components, one must include a solar tube, solenoid valve, tubing, connectors, and necessary seals. Furthermore, tools like a wrench set, screwdrivers, a drilling machine, and possibly a soldering iron could be necessary to ensure reliable connections.

The selection of quality components cannot be overstated. A high-performance solar tube will maximize solar energy absorption, while a durable solenoid valve is crucial for controlling fluid dynamics effectively. This ensures that during peak solar hours, the energy harnessed is not wasted, providing benefits throughout the day or night when regulated by an electronic control system. Tools should also be selected based on the material of the solar tube and the compatibility with piping systems.

3. SAFETY MEASURES DURING INSTALLATION

Installing a solar tube connected to a solenoid valve comes with inherent risks. Therefore, observing safety measures before commencing the process is critical. Personal protective equipment (PPE), such as gloves, goggles, and helmets, should be worn to protect against possible accidents during installation. Additionally, ensuring that electrical systems are powered down before initiating any wiring is crucial.

Moreover, checking for leaks post-connection is vital. Before connecting, ensure all piping is tested and inspected for any potential vulnerabilities or defects that could result in significant issues when the system is activated. Proper technical knowledge and experience in handling both components will significantly mitigate risks and enhance installation success.

4. CONNECTION METHODS EXPLAINED

The methodology for connecting a solar tube to a solenoid valve is pivotal in achieving seamless integration. This process often involves the use of flexible or rigid tubing to facilitate fluid transport between the solar tube and the valve. The connection can be performed in multiple ways, with the most effective being the use of push-fit connectors or threaded connectors, depending on system requirements.

When using push-fit connectors, the process is relatively straightforward and does not require extensive tools or expertise. This connection type allows easy assembly and disassembly as it is designed for quick fits without additional machinery. Conversely, utilizing threaded connections may require more robust plumbing skills. These connections, though labor-intensive, offer greater reliability against high-pressure systems.

5. TESTING THE SYSTEM POST-CONNECTION

The testing phase focuses on verifying the system’s operational efficiency and integrity. After completing the connections, it is crucial to perform a thorough examination of the entire setup to ensure that all fittings are secure and leak-free. Once the system is energized, closely monitor the function of the solenoid valve in response to the signals it receives.

Adjustments may be necessary depending on the results achieved during the testing phase. For instance, if the solenoid valve does not actuate properly under the influence of the solar tube’s output, troubleshooting the wiring connections should be prioritized. Additionally, ensure that the solar tube is positioned correctly relative to sunlight exposure, as this will significantly affect overall performance.

FREQUENTLY ASKED QUESTIONS

HOW DOES A SOLENOID VALVE WORK WITH A SOLAR TUBE SYSTEM?

A solenoid valve operates through an electromagnetic coil that, when energized, creates a magnetic field, moving a plunger to open or close the valve. In the framework of a solar tube system, as solar energy heats the fluid within the solar tube, the solenoid valve allows or interrupts this heated fluid flow according to demand. This dynamic interaction is key to maximizing the efficiency of the heating system. By responding to changes in pressure and temperature, a solenoid valve can be automated to optimize energy use. For example, during peak heating hours, the solenoid valve can remain open, allowing maximum hot water flow. Conversely, during times of reduced demand, the valve can close to maintain system pressure and prevent overheating.

WHAT TYPES OF SOLENOID VALVES ARE SUITABLE FOR SOLAR TUBE APPLICATIONS?

Choosing the appropriate type of solenoid valve for solar tube applications primarily depends on the fluid being transported and the pressure requirements. Generally, electromagnetic solenoid valves made from corrosion-resistant materials such as brass or stainless steel are ideal choices. These materials withstand high temperatures and pressures, common in solar thermal systems. Additionally, selecting a valve rated for the specific fluid—whether it is water or glycol—ensures compatibility and longevity. Furthermore, solenoid valves come in various configurations such as normally closed (NC) or normally open (NO), impacting how they respond under different system conditions. Therefore, the application design, along with environmental factors, plays a critical role in selecting the right valve for optimal integration with the solar tube system.

CAN A SOLAR TUBE BE CONNECTED TO MULTIPLE SOLENOID VALVES?

Certainly, a solar tube can indeed be connected to multiple solenoid valves, especially in complex systems designed for various heating tasks. For instance, in larger installations where different areas require controlled heating, employing multiple valves could enhance efficiency and response rates. Each solenoid valve can be programmed to operate independently based on the demand for heated fluid in distinct applications. However, this configuration also requires careful planning to ensure that the solar tube can maintain the necessary output to all connected solenoid valves simultaneously without significant pressure loss or system overload. Moreover, proper electrical design and robust control systems are necessary to synchronize operations, especially when multiple valves interact within the same system context.

Underlining the importance of connecting a solar tube to a solenoid valve is essential for developing an efficient renewable energy system. Proper preparation and a methodical approach enhance the chances of an effective installation. The process involves identifying key components, understanding their functionalities, ensuring safety protocols, and executing various connection methodologies with precision. Meticulously testing the system post-installation is equally vital to ascertain operational reliability. With expertise in solar tubes and solenoid valves, homeowners and businesses can create energy systems that not only save on utility expenses but also contribute towards sustainable practices. As more individuals explore renewable energy solutions, the knowledge and skill to connect such systems become invaluable. Ultimately, when executed with diligence, connecting a solar tube to a solenoid valve can yield significant benefits in energy efficiency, cost-effectiveness, and environmental conservation. Therefore, it is imperative to approach this task with the respect and professionalism it warrants to foster better and more sustainable energy solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-solar-tube-to-solenoid-valve/