Connecting a solar tube to an angle valve requires careful consideration and specific steps. 1. Gather necessary tools and materials, 2. Ensure a proper fit for the angle valve, 3. Secure the solar tube connection adequately, 4. Test for leaks before completing the installation. The connection process involves attaching the solar tube, which is crucial for harnessing solar energy, to the angle valve, allowing for efficient fluid transfer, typically in a solar heating system. Notably, having the right tools and ensuring a seamless fit between the components is vital to prevent leaks and ensure system efficiency.

1. UNDERSTANDING THE COMPONENTS

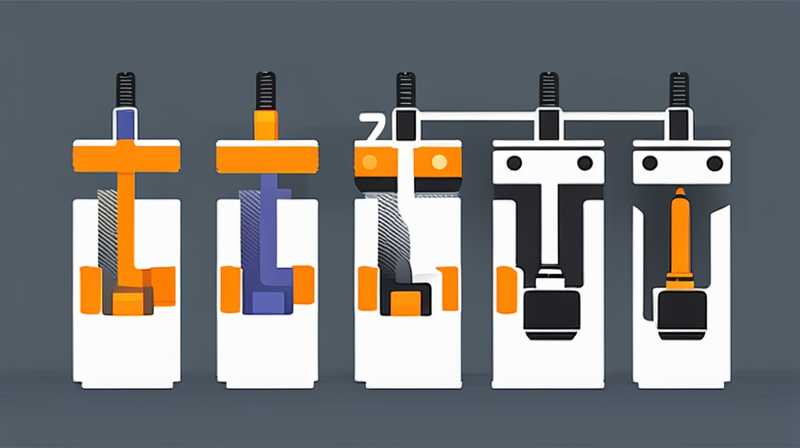

An initial comprehension of the key components involved in the solar tube and angle valve assembly is essential for a successful connection. The solar tube is often utilized for solar water heating, serving as a conduit for fluids heated by sun exposure. Conversely, the angle valve plays a pivotal role in controlling the flow of the heated liquid within the system. Each component must be compatible to ensure optimal performance.

Moreover, the angle valve is typically installed at a right angle to the pipe system, allowing for fluid control in various directions. This mechanism is crucial when directing heated water towards storage tanks or fixtures, such as radiant heating systems or domestic hot water supplies. Familiarity with these components not only facilitates a more effective installation process but also promotes maintenance efficiency in the long run.

2. SELECTING THE PROPER TOOLS AND MATERIALS

To initiate the connection of the solar tube to the angle valve, it is imperative to assemble the necessary tools and materials. Common tools for this task include wrenches, pipe cutters, Teflon tape, and sometimes a heat gun. The choice of these implements allows for precision in cutting and joining.

Selecting the correct materials, such as high-quality pipes and fittings that resonate well with the solar tube and angle valve, significantly impacts the durability and reliability of the entire system. The compatibility of materials will influence factors like thermal expansion and contraction, which can lead to leaks if not accounted for. Hence, investing time in gathering these tools and ensuring material quality forms the foundation of a successful installation.

3. PREPARING FOR INSTALLATION

Once tools and materials are at hand, the next step is preparing the components for installation. Clean the surfaces of both the solar tube and the angle valve thoroughly. This step is crucial to remove any dirt, grease, or previous adhesives that could interfere with a secure connection.

After ensuring cleanliness, it’s essential to measure the length of the solar tube needed to reach the angle valve without strain. Accurately cutting the tube aids in maintaining an effective flow of heated fluid while reducing potential stress points that could lead to breakage or leakage. Additionally, considering the angle of the connection is vital for achieving the most efficient flow dynamics within the system.

4. SECURING THE CONNECTION

When attaching the solar tube to the angle valve, the securing of the connection can be accomplished through different methods depending on the type of valve and tube used. For threaded connections, applying Teflon tape around the threads is recommended to ensure a leak-proof seal. Adequate tightening using a wrench is necessary, but caution should be exercised to avoid over-tightening, which might damage the components.

For fittings that require adhesives or sealants, selecting products rated for high temperatures is crucial. Follow manufacturer instructions for curing times and application to maximize effectiveness. Proper securing of the connection not only serves immediate operational needs but significantly contributes to the longevity of the entire system.

5. TESTING FOR LEAKS

After the installation process, testing for leaks becomes a non-negotiable task. This can be accomplished through a pressurization test, where the system is filled with water and examined for any signs of leakage at the joint connections. Utilizing a mixture of soap and water can help identify leaks as bubbles form at compromised areas.

Should any leaks be detected, it is essential to address them promptly. This may involve re-tightening connections, reapplying adhesives, or in some cases, re-cutting and replacing parts of the assembly. An undetected leak can lead to inefficiency, increased energy costs, and damage to the surrounding structures. A rigorous testing approach safeguards against these potential issues.

6. INSULATING THE SYSTEM

Insulating the solar tube and associated piping is especially important in climates with significant temperature fluctuations. Proper insulation prevents heat loss, ensuring that the maximum amount of energy is transferred to the system. Various insulation materials are available, and the choice will depend on the specific needs of the installation.

Considering the installation environment is crucial when selecting insulation. In areas prone to freezing temperatures, robust insulation prevents the risk of water freezing within the tubes, which can cause significant damage. Additionally, proper insulation contributes to reducing energy costs and enhancing the overall efficiency of the solar heating system, offering both short-term and long-term advantages.

7. MAINTENANCE CONSIDERATIONS

Implementing a robust maintenance routine is crucial for the longevity and efficiency of the solar tube and angle valve setup. Regular inspections for any signs of wear or corrosion can help mitigate issues before they develop into larger problems. Scheduling these checks can significantly extend the life of both the solar tube and valve components.

Moreover, keeping an eye on performance indicators, such as the temperature of the water being circulated or the time taken to heat water, can alert users to potential inefficiencies. Addressing minor repairs or adjustments proactively can save substantial costs in the future, making regular maintenance a worthwhile investment.

COMMONLY ASKED QUESTIONS

WHAT TYPE OF SOLAR TUBE IS BEST FOR USE WITH AN ANGLE VALVE?

The optimal solar tube largely depends on the intended application and the specific requirements of your solar heating system. Evacuated tube collectors tend to be more efficient for heating purposes, as they capture sunlight from various angles. These tubes are particularly suitable for climates with short sun durations as they retain heat efficiently.

Conversely, flat plate collectors might be a reasonable choice for warmer regions with abundant sunlight, as they are less costly and easier to install. It’s essential to consider factors such as local climate, installation space, and budget when choosing the right solar tube for your system. Conducting a thorough assessment and possibly consulting with a professional ensures that the selected components align with your heating goals.

HOW LONG DOES IT TAKE TO INSTALL A SOLAR TUBE AND ANGLE VALVE?

The duration required to install a solar tube and angle valve can vary based on several factors, such as installation experience, component complexity, and environmental conditions. Typically, a skilled professional may complete the installation within half a day to a full day. However, for individuals without prior experience, it may take longer.

Factors impacting the timeframe include preparing the site, cutting and fitting the components, securing connections, and conducting testing. Implementing a well-planned approach and allowing for unexpected adjustments or complications can help streamline the process, making it more efficient. Investing adequate time and effort during installation not only ensures a thorough job but contributes to the system’s overall success.

IS PROFESSIONAL HELP REQUIRED FOR THIS INSTALLATION?

While connecting a solar tube to an angle valve is certainly achievable for many DIY enthusiasts, the complexity of the installation may warrant professional assistance, particularly for those lacking plumbing experience. Hiring a licensed contractor can guarantee that the installation adheres to industry standards, reducing the risk of leaks or inefficiencies.

Additionally, professionals can assist in obtaining necessary permits and ensuring that the setup conforms to local building codes. A well-executed installation by an experienced technician can lead to greater reliability and performance of the solar heating system, making it a worthy consideration for those unsure of their plumbing capabilities.

In summary, connecting a solar tube to an angle valve involves several critical steps that, when executed correctly, ensure optimal performance. Ensuring compatibility of the components mitigates future issues. Proper tool selection, site preparation, secure connections, and routine maintenance are paramount for success. Furthermore, awareness of the right materials, installation techniques, and regular testing can significantly contribute to system efficiency and longevity. Taking the time to understand and implement each of these elements not only enhances the immediate setup but also promotes the long-term viability and efficacy of the solar heating system. Engaging with professional services, when necessary, can ensure that the connection adheres to high standards, reducing the likelihood of complications down the line. Ultimately, a knowledgeable approach to installation creates a foundation for renewable energy use and harnesses the incredible benefits that solar technology offers.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-solar-tube-to-angle-valve/