1. Connecting solar panels to purlins requires a systematic approach to ensure stability and functionality. 2. Ensure that the purlins are structurally sound and properly aligned. 3. Use suitable mounting hardware that aligns with both the solar panel frame and the purlin dimensions. 4. Make sure to regularly check the connections and fixtures for any signs of wear or damage. The process begins with evaluating the structural integrity of the purlins. A sound attachment not only contributes to the longevity of the solar installation but also maximizes energy efficiency.

1. UNDERSTANDING PURLINS

To effectively connect solar panels to purlins, familiarity with purlins and their purpose is essential. Purlins are horizontal members used in roof construction to provide structural support. They act as a crucial intermediary between the building’s rafters and the roof itself, facilitating the mounting of various systems like solar panels. Their strength and stability directly impact the success of any mounted system placed upon them.

When inspecting purlins for solar panel attachment, it is vital to ascertain the material, typical in wood or metal. Wooden purlins may offer ease of installation yet can suffer from rot and warping over time, diminishing their reliability. On the other hand, metal purlins boast durability and resistance to environmental wear and tear, making them an optimal choice for long-term solar installations. Each type comes with specific considerations when it comes to mounting solar panels effectively, and assessing their viability will initiate the installation process appropriately.

2. SELECTING MOUNTING HARDWARE

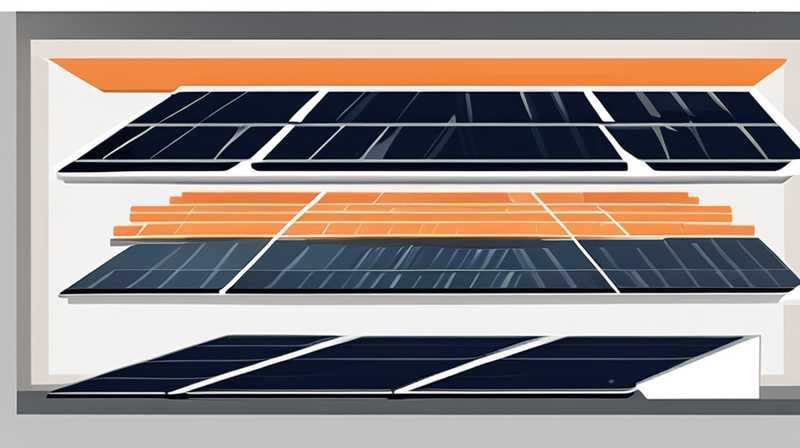

Selecting the right mounting hardware is critical when connecting solar panels to purlins. The hardware acts as the bridge that facilitates the attachment of the solar panels to the purlins while ensuring safety and stability. Common hardware options include L-brackets, mounting clamps, and specific solar mounting rails, each designed to hold panels in place securely against various environmental conditions.

Installation requirements may differ based on local building codes and the type of solar panels being utilized. Hence, it is advisable to consult a professional or refer to specific guidelines when selecting hardware. Using mounting material made from aluminum or stainless steel can prevent rust and ensure enhanced longevity. When determining the arrangement of solar panels on the purlins, attention to angle and spacing maximizes exposure to sunlight while maintaining structural integrity.

3. TOOLS REQUIRED FOR INSTALLATION

Equipped with the right tools is crucial for achieving a smooth solar panel installation. Essential tools include a drill, impact driver, socket set, measuring tape, level, and appropriate fasteners. Each tool serves a unique purpose aimed at ensuring a robust installation.

Drills facilitate the creation of holes in the purlins, enabling the secure fitting of mounting hardware. The impact driver assists in driving screws into the purlins with minimal effort, thereby speeding up the installation process. Proper measurement is critical—accurate dimensions guarantee the correct positioning of panels and prevent future mishaps. Lastly, a level ensures that the solar panels rest uniformly to maximize energy capture, reducing potential energy losses due to improper alignment.

4. INSTALLATION PROCESS

Embarking on the installation process entails several crucial stages. Initially, start by measuring the designated area for the solar panels on the purlins. Ensuring adequate orientation toward the sun’s path will considerably enhance energy generation efficiency. Based on the measured dimensions, outline the positions where the mounting hardware will be attached.

With a compelling plan in mind, proceed to install the mounting rails onto the purlins. Ensure that these rails are anchored firmly, adhering to the recommended torque specifications provided by the manufacturer. This stage is paramount, as improper attachment can lead to panel detachment over time, especially during dynamic weather conditions. Once the rails are securely mounted, carefully place the solar panels on the hardware and fasten them appropriately. Inspect each connection to confirm security before proceeding to the next steps of the installation.

5. MAINTENANCE FOCUS

Vigilance in maintenance ensures the longevity and effectiveness of solar panels mounted on purlins. Regular inspections should be conducted to identify any deteriorating components or hardware fatigue. This includes checking for rust, corrosion, or physical damage that could compromise stability.

In addition, ensure that surrounding areas are kept clear of debris or vegetation that may obstruct sunlight or potentially fall onto the panels. Establish a maintenance schedule that encompasses thorough cleaning of the solar panels because accumulated dirt and grime could diminish their efficiency. This proactive approach to maintenance aids in preserving the value of the solar installation and supports uninterrupted performance.

FREQUENTLY ASKED QUESTIONS

WHAT ARE PURLINS?

Purlins serve as horizontal supports in roofing systems, functioning as critical components that connect to the rafters. Typically found in structures like barns and industrial buildings, they support the roofing materials and offer a platform for mounting utilities such as solar panels. Without their sturdy presence, solar panels could become unstable, risking damage and loss of efficiency in energy generation. Purlins are constructed from various materials, including wood, steel, or aluminum, each influencing the installation techniques and methods used during the mounting process.

Understanding the characteristics of purlins is vital for decisions regarding mounting hardware. For example, wooden purlins may require specialized fasteners to avoid splitting, while metal purlins often necessitate drilling holes precisely to secure bolts effectively. When selecting a purlin type for solar panel installation, considerations about weather resistance and structural integrity will guide the selection.

HOW DO YOU MAINTAIN SOLAR PANELS?

Efficient maintenance of solar panels entails a multifaceted approach to ensure optimal performance. Primarily, regular inspections are crucial, as they enable the identification of potential issues. Key areas of focus include visible damage to panels, connections, loose hardware, and the presence of dirt or debris obstructing sun exposure.

Cleaning the panels with appropriate methods is another pivotal aspect of maintenance. Using non-abrasive materials and safe cleaning solutions helps retain panel integrity while eliminating dirt accumulation that can hamper performance. Monitoring energy generation levels can signal inefficiencies or malfunctions, allowing operators to address issues proactively.

Furthermore, periodic evaluations of the mounting system also contribute to preserving the installation’s integrity. Aging components should be assessed, and replacements undertaken when needed to prevent cascading failures and ensure the installation remains effective over its lifespan.

WHAT TYPE OF MOUNTING HARDWARE IS NEEDED?

The selection of suitable mounting hardware primarily depends on the type of solar panels being installed and the characteristics of the purlins. Common hardware includes L-brackets, rail systems, and clips that cater to unique installation requirements.

Compatibility with the dimensions and materials of both the solar panels and purlins ensures that the chosen mounting system will provide secure attachment. Hardware configurations may vary in design and material composition, emphasizing the importance of adherence to manufacturer specifications. The use of durable materials, such as stainless steel or aluminum, enhances resistance to weather-related wear, thereby prolonging the life of the installed system.

Installation guidance should also be consulted, where torque specifications will assist in achieving optimal securement levels. Ensuring that the mounting hardware is robust enough to withstand environmental pressures, such as wind or snow loads, is critical to the effectiveness of the solar panel setup.

The successful connection of solar panels to purlins not only enhances energy efficiency but also contributes to sustainable energy solutions for various applications. It necessitates the consideration of multiple factors, including proper purlin material choice, efficient mounting hardware selection, effective installation techniques, and ongoing maintenance practices. A meticulous examination of these components ensures that solar installations can yield consistent energy output throughout their lifespan. By prioritizing quality in each of these areas, one can develop a robust solar energy system capable of withstanding time and environmental stresses while delivering reliable performance. Moving forward, it is crucial to educate oneself further about advancements in solar technology and methodologies to optimize installations effectively. Emphasizing eco-friendly solutions plays an integral role in shaping a sustainable future, and understanding how to connect solar panels efficiently serves as a key chapter in this larger narrative.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-solar-panels-to-purlins/