To connect solar iron pipes, one must consider several essential steps and methodologies, which include 1. understanding the types of fittings needed, 2. ensuring proper dimensions and measurements, 3. selecting an appropriate sealant, and 4. adhering to local regulations and safety standards. Among these, a critical consideration is the selection of the proper fittings, as the right components will not only facilitate a secure connection but also enhance the integrity and longevity of the entire system. It is vital to ensure that fittings are compatible with the pipe specifications to prevent leaks and failures down the line.

1. TYPES OF FITTINGS AND CONNECTIONS

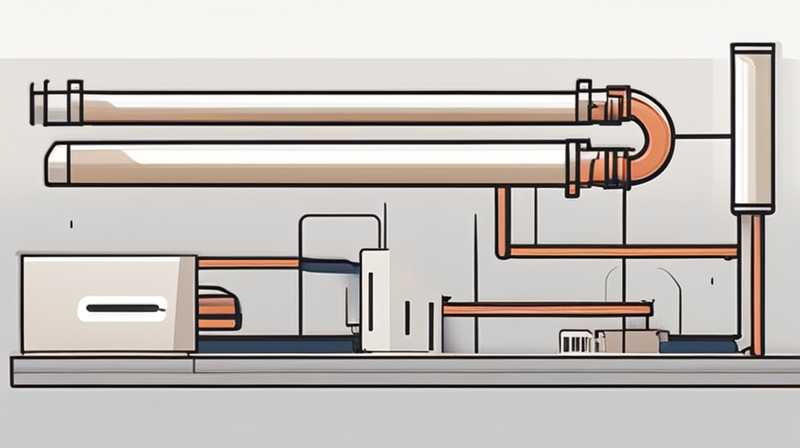

In the world of solar iron pipes, two primary categories of connections exist: threaded fittings and welded joints. Threaded fittings are usually preferred for their ease of assembly and disassembly. They involve the use of specialized threads cut into the edges of the pipe. These threads then connect to corresponding threaded fittings, usually made of either the same or compatible materials. This method is advantageous for areas where future maintenance is anticipated, as it allows for the easy replacement of components without needing to sever the pipe.

On the other hand, welded joints are regarded as more robust and permanent solutions. This method involves melting the ends of the pipe fittings to create a seamless bond. The advantage here lies in the strength of the connection; welded joints can withstand high pressure and fluctuations in temperature, making them ideal for solar applications prone to such variations. However, the installation of welded joints may require professional assistance, as it involves specialized tools and skills, significantly increasing both initial time and cost investment.

2. MEASUREMENTS AND DIMENSIONS

Accurate measurements are indispensable when connecting solar iron pipes. Precision ensures that the fittings chosen can accommodate the dimensions of the pipes perfectly, thereby avoiding leaks and ensuring there is no compromise on system efficiency. To achieve the best results, one must utilize tools like calipers or tape measures to obtain the internal and external diameters of the pipes. Recording these measurements accurately can spare the installer a considerable amount of future hassle.

In addition to the initial width and diameter measurements, installers should also take into account the lengths needed for connection. Planning for how much of the pipe will be inside the fittings is crucial, as it can vary based on the type of connection made. An underestimation here could not only lead to structural weaknesses but can also impact the overall efficacy of the solar heating system. This level of detailed calculation inevitably enhances reliability in the long run.

3. SELECTION OF SEALANTS

Choosing the right sealant for solar iron pipe connections is another critical aspect of the installation process. Sealants play a crucial role in preventing water leakage and ensuring that the pipes remain intact under varying temperature conditions. The most commonly used sealants in solar applications include thread sealants and silicone-based sealants.

Thread sealants are particularly beneficial for threaded fittings, as these substances fill the gaps between the threads, creating a waterproof seal that can withstand high temperatures. On the other hand, silicone-based sealants are advantageous for areas that may experience slight movements or vibrations, as they are flexible and allow for some degree of expansion and contraction. Regardless of the type utilized, applying these sealants judiciously will significantly mitigate risks associated with water leakage and environmental infiltration.

4. ADHERING TO LOCAL REGULATIONS AND SAFETY STANDARDS

Before commencing any physical connection of solar iron pipes, it is imperative to consult local building codes and regulations. These codes often dictate not only the materials that are permissible for use but also the installation processes that must be adhered to. Failing to comply with these regulations can lead to excessive fines and costly rework.

In addition to legal ramifications, safety standards are equally pivotal. Solar installations must not only perform effectively but they must do so safely to prevent hazards such as structural failures or fires. Consult with local authorities or organizations specializing in building codes can provide vital insight into the best practices to follow during the installation process, thereby ensuring both lawful compliance and safety for the users.

COMMONLY ASKED QUESTIONS

HOW DO I DETERMINE THE SIZE OF THE SOLAR IRON PIPES?

To determine pipe size accurately, begin by assessing the flow rate requirements of your solar heating system. Consult the specifications for the solar collectors, as they usually indicate the necessary pipe diameter for optimal flow. The type of pump used also significantly impacts this measurement; larger pumps may require bigger pipes to prevent flow resistance.

After identifying the flow requirements, utilize a tape measure or caliper to assess the diameters of existing pipes or fittings to ensure compatibility. If installing a new system, manufacturer’s guidelines often provide the ideal pipe dimensions based on collector size and intended use.

Ultimately, the selection of improper pipe sizes can lead to inefficiencies, reduced performance, or increased energy consumption. This highlights the necessity for accuracy in measurements throughout the installation process.

WHAT TOOLS DO I NEED TO CONNECT SOLAR IRON PIPES?

The tools required for connecting solar iron pipes vary depending on the type of fittings chosen and the specific installation method. However, a standard toolkit should include basic hand tools such as wrenches, pipe cutters, and thread sealant, as well as specific tools such as a welding machine if opt for welded joints.

Wrenches are indispensable for tightening threaded fittings, while pipe cutters provide clean edges for further attachments. In addition to these tools, some installers may find heat sources or equipment necessary for soldering or welding, particularly if their installation requirements call for metal-to-metal connections.

In preparation for the installation, it’s advisable to conduct a comprehensive assessment of the specific tasks needed, ensuring that all necessary tools are readily available. Missing essential tools might lead to costly delays or inadequate connections.

CAN I INSTALL SOLAR IRON PIPES MYSELF?

The installation of solar iron pipes can be undertaken as a DIY project, provided that one possesses a suitable understanding of mechanical principles and is familiar with plumbing tasks. However, there are benefits to recruiting professional help. Professionals can offer experience and knowledge that translate into improved efficiency, accuracy, and safety.

When undertaking installation independently, ensure to thoroughly research and understand all methods and requirements. Having access to the right tools and materials is crucial, as is the capability to verify that measurements are accurate and compliant with local regulations.

Ultimately, while self-installation is certainly feasible, seeking an expert’s assistance ensures the peace of mind that comes from knowing the job is completed to industry standards, which can save both time and money over the long term.

Connecting solar iron pipes requires meticulous attention to multiple factors encompassing fittings, measurements, sealants, and compliance with safety regulations. Engaging with this process meticulously can lead to a highly efficient, durable, and safe installation that not only maximizes the performance of the solar heating system but also adheres to necessary codes and standards. The choice of fittings—whether they are threaded or welded—has a significant impact on the overall efficiency and functionality of the system. Additionally, ensuring precise measurements is key to avoiding leaks and ineffective connections. Sealants should not be overlooked, as they provide an essential layer of security against potential leaks. Seeking compliance with local regulations and safety standards cannot be understated; doing so helps safeguard both the installation and the individuals working on it. Through proper planning and execution, one can achieve a robust connection that enhances the overall efficacy of the solar setup. Furthermore, staying informed about the necessary tools and techniques can ease the process and improve the chance of successful installation—whether undertaken independently or by a qualified professional. Making smart decisions during this planning stage will lead to a system poised to deliver lasting performance and reliability.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-solar-iron-pipes-2/