Connecting a solar energy meter to a solenoid valve involves a few specific steps to ensure proper function and efficiency. 1. First, identify the correct components needed for the installation. This includes acquiring a solar energy meter that is compatible with your solar panel setup and a solenoid valve designed for the specific application, such as irrigation or water flow control. 2. Next, gather the necessary tools to facilitate the installation. Tools like a multimeter, wire strippers, and connectors are essential. 3. Connect the solar energy meter to the power source. This requires careful adherence to wiring diagrams provided by both the solar energy meter and the solenoid valve. 4. Finally, test the entire setup to ensure that the solenoid valve activates and deactivates according to the readings from the solar energy meter. Thorough testing ensures reliability in operation and helps avoid any potential damage to the system.

1. COMPONENTS USED IN CONNECTION

Connecting a solar energy meter to a solenoid valve does not merely entail linking two devices; it requires an understanding of various components essential for seamless integration. The primary components include the solar energy meter, a solenoid valve, power cables, connectors, and control circuitry. Each component plays a pivotal role in the successful operation of the system.

The solar energy meter functions as a key device that measures the amount of solar energy produced by the photovoltaic panels. It quantifies solar output, hence enabling active management of the energy harnessed from the sun. Knowing the energy levels available is critical as it dictates whether the solenoid valve should open or close, thereby regulating fluid flow.

Additionally, the solenoid valve itself is an electromechanical device used for controlling the flow of liquid or gas. It requires specific voltage ratings to operate effectively. Thus, choosing the right solenoid valve ensures compatibility and prevents operational inefficiencies. Understanding the operational specifications of both the solar energy meter and the solenoid valve ensures a harmonious relationship between these components.

2. PLANNING THE INSTALLATION

Prior to actual installation, meticulous planning lays the groundwork for success. Determining ideal locations for both the solar energy meter and the solenoid valve is crucial. Conditions such as sunlight exposure, accessibility, and structural integrity should inform these decisions.

Furthermore, consider assessing the existing system setup, including any piping or wiring currently installed. Identify potential obstructions or modifications needed in advance, which can streamline the entire process. Engaging in a comprehensive assessment of the existing layout minimizes the chances of unforeseen complications arising during installation.

Taking time to map out the entire installation process also helps in estimating timelines. Allocating sufficient time is necessary for both initial setup and subsequent testing phases, as rushed installations often lead to errors. Documenting a step-by-step process enhances organization and clarity, allowing for seamless execution.

3. PREPARING FOR ELECTRICAL CONNECTIONS

Following thorough planning, attention turns toward preparing the electrical connections. Safety is paramount at this stage, as all installations involve potential hazards. Prior to manipulating wires or electrical components, ensure that the power supply is disconnected.

Start by stripping the ends of the cables that will connect the solar energy meter to the solenoid valve. A clean cut allows for efficient connections, minimizing resistance and risk of failure. Proper stripping techniques involve using wire strippers to avoid damage to the copper wires while ensuring a sufficient length is exposed for connectivity.

Verify that connectors and terminals meet necessary specifications for voltage and current. Using the appropriate connectors guarantees secure and lasting connections over time. Inadequate connections can lead to overheating or malfunction, ultimately causing system failure.

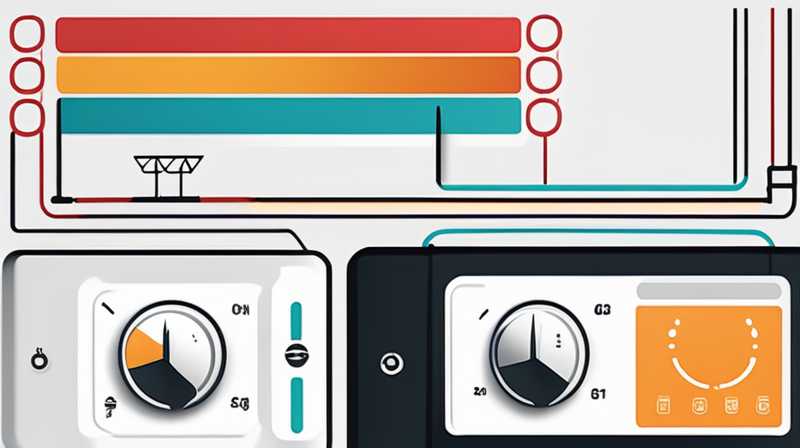

4. MAKING THE CONNECTIONS

With all preparations complete, focus shifts toward actual connection. Begin by connecting the solar energy meter to the power source. Ensure that connections correspond with the wiring diagram provided by the manufacturer. Each terminal must be carefully wired to prevent incorrect linkages, which could cause detrimental effects to both the meter and the solenoid valve.

Following the connection of the solar energy meter, proceed to link the solenoid valve. Like the previous step, each connection must be meticulously checked to confirm accuracy and safety. This involves adhering to polarity and ensuring that all wiring is properly insulated to prevent shorts.

Once both devices are correctly wired, it is prudent to utilize a multimeter to perform a continuity test. This step ensures electrical paths are clear, confirming that there are no breaks or shorts within the circuitry. Only when all conditions are verified as suitable should the power supply be reconnected.

5. TESTING THE SYSTEM FUNCTIONALITY

Upon completing the physical connections, the next phase involves rigorous testing of the entire system. Functional verification is essential to ascertain that both the solar energy meter and the solenoid valve interact efficiently. Begin by observing readings on the meter while simulating conditions that would prompt activation of the solenoid valve.

Pay attention to the response times for the solenoid valve when the energy meter signals a command. Establishing that the valve opens and closes as expected confirms operational efficacy. If discrepancies arise, conduct troubleshooting by reviewing each connection to ensure adherence to the original schematic.

Moreover, testing should encompass various scenarios. Simulating differing solar conditions allows for assessment of systems under varied output levels. Such evaluations are vital, as they ensure the automatic operation of the solenoid valve under different environmental conditions, further enhancing system reliability.

6. MAINTAINING THE SYSTEM FOR LONG-TERM FUNCTIONALITY

With the installation complete, a focus on maintenance becomes paramount. Regular inspections and upkeep prolong the operational lifespan of both the solar energy meter and the solenoid valve. Establishing a maintenance schedule ensures that potential issues are identified and rectified before they escalate into severe problems.

Conduct periodic visual checks on both devices to detect wear and frayed connections. A proactive approach to finding faults can prevent sudden failures. Additionally, ensuring that the solar panel array remains clean optimizes energy generation, which directly impacts the efficiency of the entire system.

Furthermore, it can be beneficial to assess the operational data from the solar energy meter periodically. Monitoring energy production trends and correlating them with solenoid valve activity provides insight into system functionality. With such data analysis, informed decisions can be made to enhance the integration of solar energy solutions in the future.

FREQUENTLY ASKED QUESTIONS

HOW DOES A SOLAR ENERGY METER WORK?

A solar energy meter operates by measuring the amount of electricity produced by photovoltaic panels. This device calculates the energy generated in kilowatt-hours (kWh) and can be utilized to monitor performance and efficiency. It provides important feedback on how much energy is available for use, allowing users to manage their energy consumption accordingly.

Solar energy meters often come equipped with features that allow for remote monitoring. Users can track energy production data over time to identify patterns and optimize usage. Accurately monitoring solar energy helps in making informed decisions regarding energy allocation and conservation, thereby maximizing the benefits of renewable energy harnessed from sunlight.

Additionally, many solar energy meters can interface with other devices in the system, including controllers for switching on or off appliances like a solenoid valve. The integration of these systems leads to more efficient energy management and helps automate various functions. Understanding how the solar energy meter operates is vital for anyone looking to effectively utilize solar energy technologies.

WHAT TYPES OF SOLENOID VALVES CAN BE CONNECTED TO A SOLAR ENERGY METER?

When considering solenoid valves compatible with solar energy meters, several types stand out, particularly in applications like irrigation or fluid control. Common types include normally closed, normally open, and latching solenoid valves. Each type serves distinct operational needs; thus, understanding their functions is critical to selecting the appropriate one for the intended application.

Normally closed solenoid valves shut off the flow of liquid or gas when no electrical power is supplied. This type is particularly beneficial for applications that require fail-safe operations. Conversely, normally open solenoid valves allowing flow until energized, can be ideal for settings where consistent flow is necessary, but should be quickly shut off when electrical power is absent.

Latching solenoid valves provide an advantageous alternative, as they maintain their position without continuous power, conserving energy. Such valves can be particularly effective in solar setups, where energy efficiency is a priority. Ultimately, the decision regarding which type of solenoid valve to use should align with the specific operational requirements and ensure compatibility with the solar energy meter.

WHAT SAFETY MEASURES SHOULD BE TAKEN DURING INSTALLATION?

Engaging in safe practices is critical when installing a solar energy meter with a solenoid valve. First and foremost, ensure the power supply is disconnected prior to any electrical work. This simple precaution can prevent electrical shocks or accidents during the connection process.

Employ protective gear, such as insulated gloves and safety goggles, to shield against potential hazards. Electrical installations can carry inherent risks, and employing protective measures safeguards against unforeseen events. Furthermore, using insulated tools minimizes the chances of unintended short circuits, contributing to the safety of the installation process.

Lastly, follow the manufacturer’s guidelines meticulously, as they often contain specific safety instructions pertinent to the devices being used. Adhering to these guidelines helps mitigate risks associated with electrical installations. By maintaining high safety standards, individuals can ensure that their installation process is both efficient and secure.

In summation, connecting a solar energy meter to a solenoid valve is a multifaceted procedure that requires careful planning, execution, and ongoing maintenance. Understanding the critical components involved, establishing a clear plan for installation, making precise electrical connections, thoroughly testing the system for reliability, and committing to regular maintenance will facilitate optimal functionality and performance. Additionally, safety during installation cannot be overstated, as proactive measures will reduce the risks associated with electrical work. Engaging in these practices will likely lead not only to successful integration of renewable energy solutions into everyday systems but also to long-term sustainability, maximizing the beneficial impact of utilizing solar energy to power various applications. Ultimately, adhering to the guidelines set forth during the process ensures that the connection serves its intended purpose efficiently and effectively, paving the way for more innovations in the realm of solar energy integration.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-solar-energy-meter-to-solenoid-valve/