1. Connecting solar display circuit boards involves a few key steps: 1, understanding the components involved, 2, correctly wiring the circuit, 3, programming the control unit, 4, ensuring proper power supply. Each of these aspects is crucial for functional performance. To elaborate, wiring provides the foundation for voltage and data transmission; incorrect connections can lead to system failure or inefficiency. Achieving a successful configuration of these elements can maximize efficiency and ensure that the solar display operates as intended.

1. UNDERSTANDING THE COMPONENTS

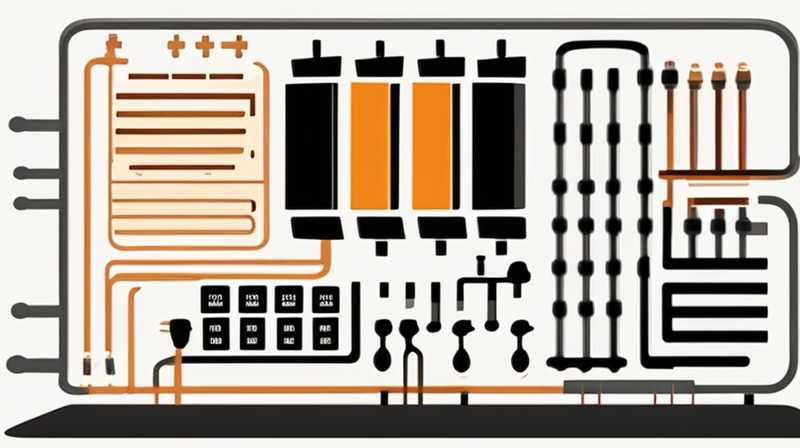

To initiate the process of connecting a solar display circuit board, it is imperative to first grasp the specific components required for the setup. Typically, a solar display system includes a solar panel, a charge controller, a battery, an inverter, and the display circuit board itself. Each piece plays a critical role in harnessing solar energy and converting it into the necessary output for the display.

The solar panel functions as the primary energy collector, absorbing sunlight and converting it into electrical energy. This electrical energy is then directed to the charge controller, which manages the flow of electricity to the battery. The battery serves as a storage unit, allowing energy to be retained and accessed even when sunlight is unavailable. Lastly, the display circuit board is responsible for interpreting and presenting this data in a user-friendly manner.

With a clear understanding of these components, one can recognize the importance of appropriate selection and compatibility. Each part must work effectively together to optimize the entire solar display system’s performance. Incorrect component selection can cause inefficiencies, leading to an underperforming setup.

2. CORRECT WIRING OF THE CIRCUIT

Once the components are identified, the next significant task involves the proper wiring of the circuit. This step is vital, as it ensures that electrical energy flows seamlessly from one component to another. Initially, it is essential to refer to the manufacturer’s wiring schematic, which provides detailed illustrations of how each connection should be established.

The wiring process typically begins with connecting the solar panel to the charge controller. This connection must be secured properly to prevent any interruptions in power flow. Special attention should be paid to ensuring that the correct polarity is observed; connecting the positive terminal of the solar panel to the positive terminal of the charge controller is essential, as incorrect connections can cause damage.

Following this, the charge controller is connected to the battery. This step also requires careful attention to polarity and connection orientation. Most charge controllers will feature specific terminals for battery connections, clearly labeled to avoid confusion. Moreover, a dedicated fuse should always be implemented in this circuit to protect against surges and potential short circuits. Adequately securing all connections with appropriate terminals will ensure a robust wiring setup.

After establishing the connections between these primary components, the next phase involves linking the display circuit board to the charge controller. Typically, this may involve data wires that transmit performance data from the charge controller to the display unit. Here, it is crucial to ensure that the data connections are made according to the manufacturer’s specifications. This wiring process directly impacts the accuracy of the data presented on the display.

3. PROGRAMMING THE CONTROL UNIT

Once the wiring is complete, the focus should shift toward programming the control unit associated with the solar display circuit board. Programming this unit is essential for ensuring that it accurately interprets the data received and displays the appropriate information. The programming process may vary depending on the specific model of the display and controller being used.

Initially, the control unit often requires initial setup, which may include configuring preferences for display outputs, data logging intervals, and other performance metrics. Many modern solar display systems feature user-friendly interfaces that enable individuals to navigate setup commands with ease. However, it is imperative to consult the instruction manual or technical documentation accompanying the unit while programming to enhance accuracy and efficiency.

Additionally, more advanced programming could include integrating smart technology features. Many systems now allow for remote access, enabling users to monitor their solar display’s performance from tablets or smartphones. This integration often involves connecting the control unit to Wi-Fi or using Bluetooth technology. Clear instructions must be followed to ensure successful connectivity.

Moreover, calibration of the display may be necessary to ensure that the information presented is accurate and reliable. Calibration involves configuring settings to match the environmental parameters in which the system operates. This step ensures the display provides real-time, relevant data that reflects the system’s performance accurately.

4. ENSURING PROPER POWER SUPPLY

As the connection journey progresses, ensuring an adequate power supply to the solar display circuit board becomes critical. The configuration must allow for optimal charging and energy retention from the solar panel to the battery. Without proper management, the display might be powered inadequately or may suffer from energy losses.

To begin, it is important to verify that the power supply is sufficient for the demand placed on the solar display system. This analysis may require calculating the total wattage that the display and its accompanying components will necessitate. The solar panel must produce enough wattage to meet these demands consistently. If there is a mismatch, one may need to evaluate whether to upgrade the solar panel or implement additional panels.

Additionally, regular maintenance checks are crucial to prevent degradation of the components involved over time, which can negatively affect power supply. This strategy may include cleaning the solar panel to enhance energy collection and inspecting wires for any signs of wear or damage that could lead to power losses.

Implementing power management tools within the system can further enhance efficiency. These tools monitor energy input and draw and can optimize power consumption across all components involved. Using robust monitoring software can also indicate any discrepancies between expected performance and actual energy usage. By ensuring a reliable power supply, the solar display circuit board can maintain operations smoothly and accurately represent data.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLAR DISPLAY CIRCUIT BOARD?

A solar display circuit board serves as the central hub for interpreting and presenting data gathered from solar energy systems. This board allows users to visualize essential information, such as energy production levels, battery status, and performance analytics of solar panels. By translating complex data into comprehensible formats, these circuit boards facilitate informed decision-making for optimal solar energy utilization.

Typically, these boards can support various input forms, including real-time readings and historical performance data. Such features empower users to track how much solar energy has been generated over time, identify trends, and make appropriate adjustments to their solar setups. High-quality solar display circuit boards are often designed to withstand environmental challenges, ensuring longevity and reliability.

In advanced systems, smart functionalities may be integrated into the display boards, allowing for remote monitoring and control. This ability enables users to interact with their solar systems directly from their smartphones or tablets, enhancing convenience. Overall, the solar display circuit board is a crucial component that bridges the gap between technology and user experience in solar energy systems.

HOW CAN I TROUBLESHOOT ISSUES WITH MY SOLAR DISPLAY CIRCUIT BOARD?

When facing issues with a solar display circuit board, systematic troubleshooting becomes essential for identifying and rectifying the problem. The first step involves verifying power supply integrity. Check the battery’s voltage levels and assess the functionality of any connecting wires to ensure there are no loose or damaged connections. Without power, the entire solar display system will be non-functional.

Following power verification, it is crucial to examine the wiring connections throughout the system. Inspecting each wire connected to the solar panel, charge controller, battery, and display board should be a priority. Referring to the manufacturer’s schematic diagrams can provide clarity on proper connections.

If the wiring appears intact and grounded, it may be necessary to recalibrate the display settings. This process often entails reviewing the control unit’s configuration to ensure it is set up appropriately. Many units have a reset function or can be reprogrammed from scratch to restore performance.

Finally, if all else fails, consulting the user manual or contacting customer support may provide additional insights. Oftentimes, manufacturers offer troubleshooting guides specific to their products, which can help users navigate their challenges effectively.

HOW OFTEN SHOULD I MAINTAIN MY SOLAR DISPLAY SYSTEM?

Maintenance of a solar display system is crucial for promoting optimal performance and longevity. Regular inspections and upkeep help identify potential issues before they escalate into costly repairs. Generally speaking, a thorough maintenance routine should be established at least biannually, although quarterly checks could be beneficial, especially in regions with harsh weather conditions.

The maintenance process should begin with cleaning the solar panels to ensure maximum energy absorption. Dust, debris, and grime can accumulate on the panels, blocking sunlight and reducing overall efficiency. Depending on the surrounding environment, cleaning might be necessary after storms or heavy winds to maintain optimal performance.

Additionally, regular checks on battery functionality are essential. Monitoring battery health ensures that it retains adequate charge and performs effectively during periods without sunlight. Checking terminal connections for corrosion or looseness can prevent power losses.

Finally, reviewing the display unit for performance accuracy and verifying that all data logging systems function efficiently is essential. This routine helps users understand their solar energy consumption accurately and optimize their systems as needed.

**Given the significance of interconnectivity in solar display systems, the outlined processes for connecting a solar display circuit board are imperative. Mastery over the connection process ultimately dictates the efficacy and longevity of solar technology in harnessing renewable energy. Every child’s play, when equipped with appropriate knowledge, ensures smooth operational functionalities across all components involved. Engaging with the components thoroughly fosters a deeper understanding and appreciation for the detailed mechanisms driving solar energy solutions, ultimately enabling users to maximize energy efficiency and sustainability. One cannot underestimate the importance of proper wiring, meticulous programming, and ongoing maintenance in achieving optimal system performance. Leaving any of these aspects unattended might result in subpar functionality or operational inefficiencies. As more individuals gravitate toward sustainable energy solutions, becoming proficient in handling solar display systems not only empowers users but also contributes significantly to environmental conservation efforts. Investing time and resources in understanding how to connect and maintain solar display circuits represents a commitment to fostering a greener future.*

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-solar-display-circuit-board/