To connect a solar contactor, one must follow specific steps that ensure the device is wired correctly and operates efficiently within a solar power system. 1. Understand the solar contactor’s role, 2. Gather appropriate tools and materials, 3. Follow a systematic wiring process, 4. Test for functionality. The primary task involves establishing a reliable and safe connection between the solar panels and the inverter while ensuring protection against overloads and faults.

It is essential to note that a solar contactor acts as an automatic switch that manages the power flow in a solar system. This function is often crucial because it automates the control of power generated by solar arrays, ensuring that the energy is correctly routed to where it’s needed, such as charging batteries or supplying the electrical grid. The installation process should be handled with care, emphasizing safety protocols. Properly connecting the solar contactor enhances system efficiency and longevity.

1. UNDERSTANDING SOLAR CONTACTORS

Solar contactors play a pivotal role in photovoltaic installations. They are electromechanical switches that facilitate the safe and efficient transmission of electricity generated by solar panels. At their core, solar contactors protect electrical circuits from overload conditions, ensuring that the energy produced is safely managed and directed.

Essentially, these devices serve multiple functions, including disconnecting the solar array from the inverter during maintenance or in response to fault conditions. This capability is crucial, as it ensures the safety of both equipment and personnel. Understanding the operational principles of these contactors is fundamental for anyone looking to work with solar technology.

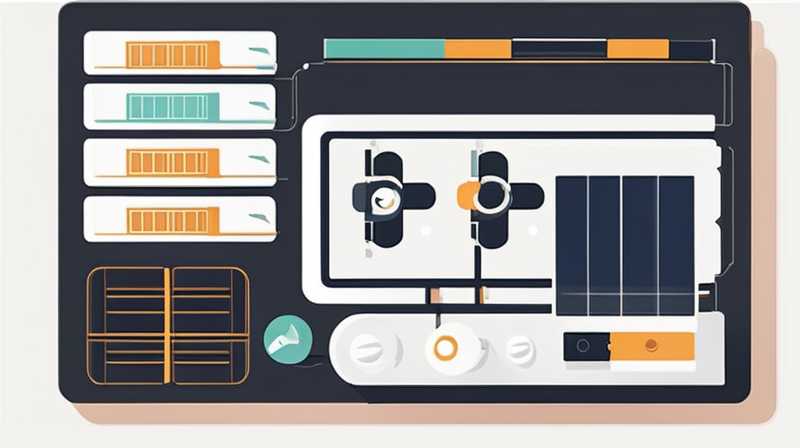

The mechanics of a solar contactor involve the use of an electromagnet that, when energized, pulls in a movable armature and closes the contacts, allowing electricity to flow. This process is reversed when the current is turned off, permitting the contacts to open again. Such dynamic operation underscores the need for proper installation and connection procedures, highlighting the importance of adhering to specified guidelines.

2. PREPARING FOR INSTALLATION

Before beginning the connection process, it is imperative to gather all necessary tools and materials. Required items typically include the solar contactor, wiring connectors, appropriate gauges of wire, screwdrivers, wire strippers, a multimeter for testing, and safety gear like gloves and goggles. Ensuring that you have all tools within reach can facilitate a smoother installation process.

Furthermore, ascending knowledge about the electrical characteristics of the solar system is essential. Prior to installation, determine the voltage and amperage specifications of the solar panels and the inverter. Such specs will guide you in selecting the correct contactor model and wire gauge to prevent overheating and ensure optimal functionality.

In addition, reading through any manufacturer instructions for the specific model of the solar contactor is critical. Each model may have particular requirements, and heeding these details will ensure a successful installation. A meticulous approach at this stage lays a firm foundation for the entire project.

3. WIRING THE SOLAR CONTACTOR

Wiring the solar contactor involves several precise steps that must be executed to maintain safety and functionality. Begin by disconnecting the power supply to the solar system to avoid any potential electrical hazards. Confirm this disconnection using a multimeter. Upon ensuring the system is de-energized, proceed with the wiring connections.

To commence, connect the power supply leads to the input terminals of the solar contactor. Typically, these connectors are labeled as L1 and L2, representing line voltage inputs. Ensure that these leads are securely clamped to prevent any loose connections, which can lead to arcing or overheating.

Next, identify the output terminals labeled T1 and T2, which direct power from the contactor to the inverter or battery storage systems. Use the appropriate wire gauge based on the current specifications of the solar array. Connecting these leads correctly is vital, as it dictates the efficiency of energy transfer throughout the system.

It is equally important to establish a grounding connection for safety. Attach the grounding wire to the designated terminal on the solar contactor, and connect the opposite end to an established grounding point within the system. This step is crucial for protecting both the equipment and personnel from potential faults or surges.

4. TESTING THE CONNECTION

After completing the wiring, proceed to verify the installation’s correctness and functionality. First, ensure all connections are tight and secure. Visually inspect the entire setup for any exposed wires or potential short-circuits.

Next, restore power to the solar system and monitor the operation of the solar contactor. Using a multimeter, measure the voltage at the input terminals. Confirm that it matches the expected levels based on the system specifications. If everything appears normal, check the output terminals for voltage to ensure that the energy flow is unaffected.

Finally, simulate an activation. This can typically be done by disrupting the input voltage momentarily to observe whether the contactor engages and disengages as intended. An operational check should include verifying that the load connected to the output terminals responds correctly to changes initiated by the contactor.

5. MAINTAINING SOLAR CONTACTORS

Like any electrical component, solar contactors require routine maintenance to operate efficiently. Regular inspections should include checking connections for corrosion, particularly in outdoor installations where weather exposure is significant. Tightening loose connections can prevent electrical failures and enhance performance.

Additionally, cleaning the contact surfaces periodically can help in maintaining efficient operation. This process of removal ensures that there is minimal resistance at the contact points, which is crucial for long-term reliability. Use specialized cleaning solutions if needed, but avoid any abrasive materials that can damage the components.

Lastly, should any operational anomalies arise, seek professional assistance. A professional electrician with experience in solar systems can diagnose issues effectively and implement necessary repairs. Practicing proactive maintenance not only extends the lifespan of the contactor but also maximizes the efficiency of the entire solar system.

FREQUENTLY ASKED QUESTIONS

1. WHAT ARE THE COMMON SIGNS OF A MALFUNCTIONING SOLAR CONTACTOR?

Common indicators of a defective solar contactor include intermittent power output from solar panels, unusual noises during operation, and signs of overheating, such as burnt marks at the terminals or a distinct odor. Inspecting for these signs promptly can prevent larger issues within the solar system. Regulatory maintenance checks are advisable, as they can allow for early detection of these symptoms. If such signs are noticed, it is crucial to disconnect the system and assess the contactor’s condition closely.

2. HOW CAN I ENSURE MY SOLAR CONTACTOR LASTS LONGER?

To prolong the lifespan of your solar contactor, regular maintenance is key. Inspect connections for corrosion and ensure wiring is secure and intact. Schedule routine checks to monitor the operational integrity of the unit and replace any worn components immediately. Additionally, maintaining proper environmental conditions can also contribute significantly to the longevity of the contactor. Ensure that it is kept free from excessive moisture, heat, or dust. Following operational guidelines established by manufacturers and consulting professionals during maintenance can also significantly enhance durability.

3. CAN SOLAR CONTACTORS BE USED IN BATTERY STORAGE SYSTEMS?

Yes, solar contactors can be effectively utilized in battery storage systems. They play a vital role in directing the electricity generated by solar panels to charge batteries. Moreover, in systems with hybrid functionality, where both solar and grid energy are in play, contactors ensure the correct distribution of energy based on operational modes. Installing a contactor in battery storage setups protects against overload risks while simultaneously facilitating efficient charging and discharging processes.

The incorporation of solar contactors in solar power systems is indispensable for enhancing safety and efficiency. Proper installation practices are paramount, greatly influencing both performance and longevity. Recognition of their integral functions—securing the flow of energy, reacting to changes in system conditions, and safeguarding equipment—must be a priority for anyone engaged in solar technology. Accurately assessing tools, gathering necessary materials, and following a structured wiring process are essential for anyone embarking on installing a solar contactor. Proficiency in maintenance can further maximize equipment reliability, ensuring uninterrupted energy generation and a longer service life. Through understanding and application of these principles, individuals can harness the full potential of solar energy systems, contributing to a sustainable energy future and reaping the rewards of efficient solar energy management.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-solar-contactor/