To connect PPR pipe to solar pipe effectively, it’s essential to follow specific procedures for a secure and reliable installation. 1. Understand the compatibility of materials, 2. Gather necessary tools and materials, 3. Use appropriate fittings, 4. Ensure proper sealing and insulation. Each of these components plays a vital role in ensuring that the connection remains leak-free and maintains system efficacy. Understanding the compatibility of the materials is particularly important, as the differences in thermal expansion and contraction between PPR and solar piping can lead to issues if not addressed.

The process begins by assessing the compatibility of the materials involved. PPR pipes are known for their durability and resistance to corrosion, while solar pipes are typically made from metals that also withstand high temperatures and pressures. The effectiveness of the connection depends largely on utilizing suitable fittings that accommodate the distinct thermal properties of each material. Proper sealing techniques and insulation measures further enhance the reliability of the connection, reducing the risk of leaks and inefficiencies.

1. UNDERSTANDING MATERIAL COMPATIBILITY

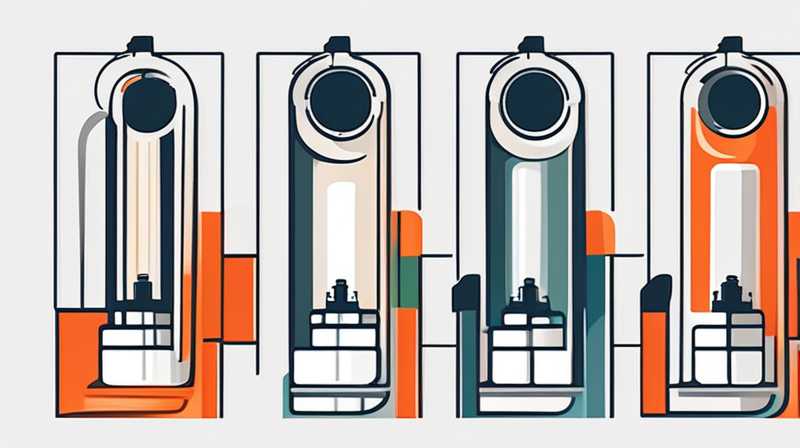

Before initiating the connection process, comprehending the material properties of PPR and solar pipe is paramount. PPR (Polypropylene Random Copolymer) is a thermoplastic polymer recognized for its resistance to chemical corrosion and its ability to withstand high temperatures, making it an ideal choice for hot water transport systems. Conversely, solar pipes, typically metallic, are designed to endure expansive temperature ranges, particularly under solar heating applications.

The thermal expansion difference between these two types of piping can lead to substantial challenges if not considered. Each material reacts differently when subjected to temperature changes, and if the connection is made without this understanding, it might lead to stress points that could result in leaks or even failure points over time. Furthermore, the type of solar pipe material—whether copper or aluminum—also influences the choice of fittings and welding methods needed for a secure connection.

Moreover, the longevity and performance of the piping system is markedly affected by the materials used. PPR and metal solar pipes can operate efficiently together if proper fittings are selected, ensuring minimal movement between the pipes that could arise from temperature-induced expansions.

2. GATHERING TOOLS AND MATERIALS

The success of the connection hinges on the collection of appropriate tools and materials. Essential tools include a pipe cutter, wrench, heat source (for thermal welding or coupling), Teflon tape, and suitable connecting fittings like couplings or unions designed to accommodate both PPR and the chosen solar pipe material.

Each tool plays a specific role in ensuring that the connection is secure and reliable. For instance, a pipe cutter enables precise cuts on both PPR and solar pipes, which is critical for achieving a flush connection. Using a wrench is crucial for tightening fittings appropriately without experiencing undue stress on the pipe joints, which could lead to subsequent issues.

Nonetheless, selecting the right fittings is crucial for a successful connection. Adapters must be available that bridge the gap between PPR and solar pipes effectively, and ensuring they are made from compatible materials is essential to facilitate effective thermal expansion. Non-corrosive materials are preferred, especially given that the solar piping will deal with significant temperature fluctuations, and any degradation in fittings can compromise the entire system.

3. USING APPROPRIATE FITTINGS

Relying upon the right fittings is one of the most critical aspects of connecting PPR to solar pipe. The choice of fittings not only supports easier installation but also ensures the system operates efficiently under fluctuating conditions. Fittings may include mechanical couplings designed specifically for transitioning between differing pipe materials.

Universal or transition fittings can be particularly beneficial when dealing with varied pipe materials. Utilizing these fittings reduces the likelihood of leaks since they are engineered to accommodate the unique properties of PPR and the metallic components of solar piping. Proper fit, in terms of diameter and alignment, is vital to maintain ideal performance of the piping system.

Further enhancing the connection performance is the consideration of sealing methods. Sealing compounds or Teflon tape applied to threaded fittings can effectively prevent leaks at junctions. In addition, for thermal welding methods, it is crucial to ensure temperature settings are appropriate; excessive heat can damage PPR, while insufficient heat may not adequately fuse the materials together.

4. ENSURING PROPER SEALING AND INSULATION

After selecting appropriate fittings, maximizing the integrity of the connection necessitates adequate sealing and insulation practices. Leak-proof connections are essential to ensure that the system maintains its efficiency and longevity. Proper sealing methods, such as adhesive sealing compounds, joint compounds, or using suitable sealing rings, can significantly mitigate potential leaks.

In addition to sealing, insulating the connection where PPR meets solar pipe is critical to prevent temperature loss and protect against condensation. Insulation sleeves or wraps can be strategically applied to prevent energy losses, which is particularly relevant for systems reliant on solar energy. By reducing heat loss, the system optimally functions, leading to savings on energy bills over time.

Addressing insulation concerns also safeguards the pipe connections from potential damage caused by atmospheric conditions. Adverse weather factors can lead to condensation or ice formation, particularly in colder climates, which can severely affect the integrity of the piping system if not insulated properly.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE BEST WAY TO CONNECT PPR PIPE TO SOLAR PIPE?

When connecting PPR pipe to solar pipe, using specialized fittings designed for transition is optimal. Ensure fittings are compatible with both materials and sealable to prevent leaks. Begin by cutting pipes to length and preparing the ends uniformly. If implemented properly, mechanical fittings or adhesive bonding can bridge the differences in material properties effectively. Proper attention to sealing and insulation is crucial for long-term performance.

CAN I USE GLUE OR CEMENT ON PPR PIPES IN SOLAR WATER SYSTEMS?

While there are specific adhesives designed for PPR pipes, standard PVC cement is not suitable due to varying thermal expansion rates. Instead, soluble adhesives that are compatible with both PVC and PPR can be used. Always check for manufacturer recommendations and ensure that any adhesive employed is specifically rated for hot water use to prevent early failure of the system.

HOW DO I KNOW IF MY CONNECTION IS LEAKING?

To detect leakage, observe the connection points visually for signs of moisture or wetness. A pressure test of the entire system can also reveal hidden leaks. Regular maintenance checks can help catch issues early. In addition, utilizing pressure gauges can give readings to ensure the system maintains stable pressure levels, indicating the integrity of the connections.

The importance of connecting PPR pipe to solar pipe effectively cannot be overstated. Ensuring a reliable, leak-proof joint means understanding the unique properties of both pipe types, utilizing appropriate tools, and selecting high-quality fittings to accommodate thermal expansion and contraction. Inadequate connections can lead to inefficiencies that compromise the system’s overall functionality, leading to increased maintenance costs or system failures. Selecting the right materials, using effective sealing methods, and incorporating insulation measures into the design are all crucial steps in achieving a successful connection. With proper planning and execution, a durable and effective connection between PPR and solar pipes can be established, ensuring that solar heating systems operate at peak efficiency and reliability. Ultimately, thorough understanding and adherence to best practices will contribute to the longevity of both the piping and the entire system. Investing time and effort into ensuring that connections are made correctly pays dividends in the form of long-lasting and efficient plumbing solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-ppr-pipe-to-solar-pipe/