Connecting pipes for solar heating systems is a critical aspect that directly influences the efficiency and effectiveness of the entire setup. 1. Pipes should be constructed from durable materials, such as PVC or copper, to withstand varying temperatures. 2. Proper insulation is essential to minimize heat loss during transmission. 3. The layout should ensure smooth flow, with minimal bends or obstructions, to maximize energy transfer. 4. Using the correct sizing for pipes maintains optimal water flow, avoiding pressure drops that could reduce performance.

Elaboration on one point: The importance of using durable materials cannot be overstated. Materials like PVC and copper are selected not just for their heat-resistance but also for their long-lasting properties. Copper, for instance, conducts heat exceptionally well, enabling an effective transfer of thermal energy from solar collectors to the water storage units. Conversely, PVC is lightweight and resistant to corrosion, making installation easier and maintenance less frequent. The longevity and performance of solar heating systems hinge heavily on these material choices. Therefore, ensuring that all components, including pipes, meet high standards of quality and durability is paramount for sustained functionality.

1. UNDERSTANDING SOLAR HEATING SYSTEMS

Solar heating systems harness sunlight to produce thermal energy for various uses, primarily in residential settings for water heating. These systems often comprise solar collectors, storage tanks, and a network of pipes for transporting the heated fluid. Understanding the fundamental components and their operations is crucial for effective installation and maintenance.

The solar collectors serve as the heart of the system, absorbing sunlight and converting it to heat. This heat is carried through a fluid (usually water or a water-glycol mixture) that flows through the pipes. The choice of collector, coupled with proper pipe connections, affects the overall efficiency and output of the system.

Additionally, the arrangement and sizing of pipes must be considered during the planning stage. Different configurations may yield varying levels of efficiency. Systems can be direct or indirect, requiring unique considerations for the pipe connections involved.

2. MATERIALS REQUIRED FOR INSTALLATION

Selecting the correct materials for pipe connections is vital for ensuring efficiency and long-term performance. The primary materials used in solar heating systems include copper, PVC, PEX, and stainless steel. Each material possesses distinct characteristics suited for different applications.

Copper pipes are often regarded as the gold standard for solar heating applications due to their superior thermal conductivity. They are particularly advantageous for high-temperature applications. However, this material can be more expensive and requires specialized skills for installation.

On the other hand, PVC pipes are favored for their cost-effectiveness and ease of installation. They are resistant to corrosion, making them suitable for a wide range of environments. Nevertheless, PVC may not be optimal for high-temperature applications as it can soften, limiting its usage in certain systems.

PEX pipes are a flexible option that simplifies installation in complex layouts. They resist scale and chlorine, thereby enhancing their longevity. However, installers should be mindful of the conditions under which PEX is used, as excessive UV exposure can compromise its integrity.

Lastly, stainless steel is utilized in scenarios where high pressure and temperatures are involved. Its resistance to rust and corrosion makes it suitable for outdoor applications where exposure to the elements is inevitable.

3. INSULATION TECHNIQUES FOR PIPEWORK

Proper insulation is indispensable for optimizing the performance of solar heating systems. Insulating the pipes minimizes heat loss and ensures that the heated fluid retains its temperature while traveling from the collectors to the storage tanks. This section delves into various insulation methods available for pipework in solar heating systems.

Foam insulation is widely used for its cost effectiveness and efficiency in minimizing thermal transfer. Typically made from polyurethane or polystyrene, foam insulation is applied in various thicknesses, depending on the specific application and local climate conditions. Employing foam that is specifically designed for high-temperature applications is crucial to maintaining the integrity of the insulation over time.

Furthermore, reflective insulation acts as a radiant barrier to prevent heat loss. It reflects thermal energy back toward the fluid, enhancing the efficiency of the overall system. This method is especially beneficial in climates with significant temperature variations between day and night.

Professionals often recommend a combination of both types of insulation for optimal results. Ensuring that joints and connections are adequately insulated is equally important, as these areas are prone to heat loss and can significantly impact the system’s overall performance.

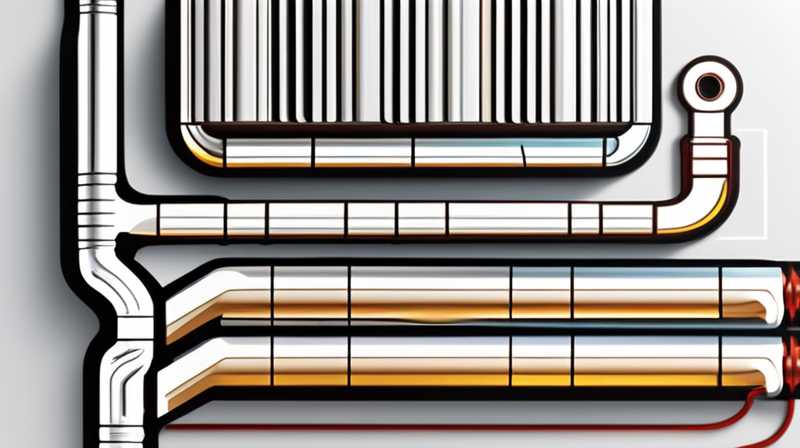

4. LAYOUT AND CONFIGURATION OF PIPES

The configuration of pipe layout profoundly influences the efficiency of solar heating systems. A well-planned layout facilitates optimal water flow and minimizes resistance. This section provides insights into the critical factors influencing the configuration of pipes in solar heating installations.

Pipe diameter is one of the crucial factors affecting flow rates and efficiency. Sizing pipes appropriately ensures that water flows smoothly without experiencing pressure drops that could hinder performance. Determining the ideal diameter requires considering the system’s requirements, including the solar collector’s capacity and the anticipated temperature rise.

Furthermore, the layout design should aim to minimize bends and turns. While it might be tempting to route pipes in a way that appears more straightforward, excessive bends can create turbulence and increase resistance. Keeping the pipe runs as direct as possible promotes unobstructed flow and heat transfer.

In addition, designing the layout to accommodate easy access for maintenance is essential. Consider where valves and fittings are placed; this planning ensures that future repairs or modifications do not necessitate extensive dismantling of the system.

5. INSTALLATION PROCESS AND TECHNIQUES

Embarking on the installation of solar heating systems necessitates a methodical approach. The installation process is not only about physical labor but also requires a deep understanding of hydronics and thermal dynamics to ensure the system’s efficiency. This section outlines key stages in the installation procedure, focusing on the vital steps involved in connecting pipes.

The initial stage includes planning and measurement. Accurate measurements are crucial before cutting and assembling any pipework. During this stage, considerations such as elevation changes, optimal routing, and potential thermal expansions must be evaluated meticulously.

Once the planning phase is complete, the actual installation process begins with cutting and joining pipes. Adhering to manufacturers’ specifications for adhesives and fittings is paramount in achieving secure joints that prevent leaks. For instance, solvent welding for PVC pipes requires specific curing times to ensure the bond’s efficacy, while soldering copper pipes necessitates a thorough understanding of heating and cooling principles to avoid joint failures.

Additionally, troubleshooting potential issues during installation is critical. Common pitfalls include improper joint fittings, insufficient support for hanging pipes, and overlooking insulation at connections. By proactively identifying and addressing these issues, the overall reliability and efficiency of the solar heating systems can be enhanced.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF PIPES ARE BEST FOR SOLAR HEATING?

The selection of pipes for solar heating applications hinges on key factors such as thermal efficiency, cost, and installation ease. Copper pipes are often lauded for their superior thermal conductivity, making them a solid choice for high-temperature applications. However, they can be expensive and require advanced installation skills. PVC pipes, while less thermally conductive, are attractive due to their affordability and ease of use in moderate-temperature environments. PEX pipes offer flexibility and resilience, making them ideal for complex configurations, though care must be taken regarding UV exposure. Ultimately, the ideal choice also considers local climate, installation settings, and budget constraints.

HOW CAN INSULATION IMPACT THE EFFICIENCY OF A SOLAR HEATING SYSTEM?

The efficiency of solar heating systems hinges significantly on effective insulation techniques. Insulation serves to minimize heat loss as heated fluids traverse between the solar collectors and storage tanks. This is particularly crucial in cold climates, where inadequate insulation can lead to substantial heat loss, undermining the system’s overall efficiency. When properly insulated, systems can maintain higher temperatures, ensuring optimal performance during periods of heavy usage. Effective insulation materials, like foam and reflective barriers, not only enhance heat retention but also prolong the lifespan of the entire system by reducing wear and tear caused by thermal cycling.

WHAT COMMON MISTAKES SHOULD I AVOID DURING INSTALLATION?

Several pitfalls can undermine the effectiveness of solar heating installation projects. A typical oversight is inadequate pipe sizing, leading to pressure drops that diminish fluid flow rates. Another aspect often overlooked is the importance of a well-planned layout, where excessive bends and turns can impede the flow. Additionally, neglecting to adequately insulate joints and connections could result in significant heat loss. Lastly, many installers fail to comply with local building codes and regulations, which can lead to legal and operational challenges. Comprehensive pre-planning and adherence to industry best practices can mitigate these mistakes.

The process of connecting pipes for solar heating is a multifaceted endeavor that demands attention to detail and a broad understanding of system dynamics. The careful selection of materials, optimal insulation techniques, and thoughtful layout configurations all play crucial roles in ensuring a successful installation. By meticulously planning each facet, installers can greatly enhance the overall performance and longevity of solar heating systems. Proper installation practices not only maximize efficiency but also contribute to the sustainability of energy resources, aligning with modern ecological and economic concerns.

Beyond technicalities, the knowledge gained about each component and its function empowers professionals to troubleshoot potential challenges effectively. The ability to recognize the implications of material choices, layout design, and insulation methods catalyzes a more comprehensive approach to solar energy applications.

Advancements in technology continue to shape the landscape of solar heating systems, promising even higher efficiencies and easier installations. The ongoing dialogue among industry experts persists, allowing for the sharing of innovations and solutions that can further enhance the performance of solar heating setups.

Ultimately, successful solar heating systems are characterized by strategic planning, informed decision-making, and diligent execution. These factors encapsulate the essence of achieving sustainable thermal energy solutions for contemporary living while reducing reliance on non-renewable energy resources.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-pipes-for-solar-heating/