To connect a data cable to a solar panel, follow these essential steps: 1. Ensure compatibility between the solar panel and the data cable, 2. Identify the correct connection points on the solar panel, 3. Use appropriate connectors to establish a secure link, 4. Verify successful communication and data transfer. In detail, ensuring compatibility is crucial since different solar panel systems may utilize various data protocols. Thoroughly checking the specifications for both devices before commencing installation prevents potential issues. This careful preparation sets the stage for a smooth and effective connection process.

1. UNDERSTANDING SOLAR DATA COMMUNICATION

Solar panels convert sunlight into electricity, but they can also communicate performance data. Data cables play a pivotal role in monitoring output and optimizing the efficiency of solar installations. Understanding the purpose of connecting a data cable to a solar panel lies in recognizing the significance of this data. Monitoring systems provide real-time insights into performance metrics such as voltage output, current levels, and energy production, contributing to informed decision-making on maintenance and efficiency improvements.

Phased deployment of various monitoring technologies means various data transmission methods are available. These may include RS485, CAN, or Ethernet protocols, which provide versatility and adaptability to different setups. Consequently, it’s essential to evaluate the specific needs of the solar panel system in question, eluding assumptions about one-size-fits-all solutions. Failing to apply tailored communication strategies could lead to inefficiencies in data representation and monitoring.

2. ESSENTIAL EQUIPMENT AND TOOLS

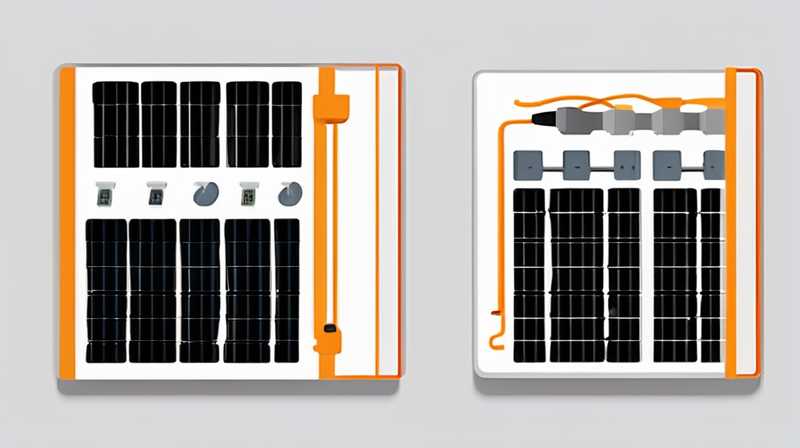

Before embarking on the connection journey, gathering the necessary tools and equipment is vital. Essential items include the correct type of data cable, connectors, and various hand tools for installation. Data cables can range from simple two-wire options to complex multi-core cables, each designed for specific applications. Matching the cable type with the solar panel specifications is crucial; handling this task with diligence will ensure longevity and effectiveness in communication.

Connectors also require consideration. Weather-resistant and durable connectors help maintain the integrity of both the electrical and data connections against environmental factors. Appropriate connectors facilitate secure links that minimize risks of disconnections or signal interference. Having adequate tools, such as wire strippers, crimping tools, and electrical tape, can ease the installation process significantly. Properly equipping oneself ensures a streamlined experience during the setup.

3. STEP-BY-STEP CONNECTION PROCESS

Carefully executing the connection process enhances the reliability of the setup. Initially, ensure that all power sources are disconnected, promoting an accident-free environment during installation. Prioritizing safety is paramount, as electricity can pose serious hazards. Wearing protective gear and following safety protocols should not be neglected during this phase.

Next, prepare the data cable by stripping the ends to reveal sufficient conductor length. This preparation allows for effective termination into the connectors. Following this, connect the data cable to the designated terminal on the solar panel; adherence to color coding and terminal marking is vital for proper functionality. One erroneous connection can lead to malfunction or lack of monitoring capabilities.

After establishing the connection, ensure all cables are securely fastened and organized to prevent damage from environmental factors or during maintenance activities. Careful organization promotes ease in future troubleshooting or upgrades. Finally, reconnect the power source and verify functionality using a compatible monitoring device or software. Conducting a systematic check ensures that data transmission operates accurately and reliably.

4. COMMON ISSUES AND TROUBLESHOOTING

Despite meticulous connections, challenges may arise post-installation. Being prepared to troubleshoot common issues enhances your capacity to maintain reliable solar operations. Frequent problems can range from cable damage due to environmental exposure to communication failures between the solar panel and the data monitoring system.

One forwarding issue centers around data loss, which could result from interference or improper grounding. Addressing grounding correctly is crucial, as ungrounded systems may expose the installation to a higher risk of fluctuations or failures. Conducting routine inspections to identify broken cables or loose connectors helps prevent larger problems down the line.

In the instance of a failed system, diagnosing the root cause is essential. Verifying power source connectivity and using diagnostic tools to analyze data output can help determine the specific technical issues. Additionally, consulting the manufacturer’s guidelines or customer support can yield tailored advice relevant to the model and type of equipment being used.

5. REGULAR MAINTENANCE AND UPKEEP

Maintaining reliable data communication between solar panels and monitoring systems requires ongoing effort. Establishing a regular maintenance schedule can significantly reduce the risk of communication failure. Routine inspections may involve checking all cable connections, assessing the condition of connectors, and confirming that environmental factors are not causing damage.

Cleaning the cables while inspecting them is equally important. Pollutants and debris can accumulate over time, causing interference or damage to the signal integrity. Ensuring that both data and power cables are clear of obstructions can help maintain uninterrupted performance. Inspecting for physical wear or degradation will also enable proactive maintenance, thus prolonging the life of the installation.

Additionally, firmware updates for monitoring systems may improve performance or resolve bugs. Keeping software current is critical in adapting to advancements in technology and ensuring compatibility with other devices. Not only will this increase operational efficiency but it may also unlock new features to enhance your system’s capabilities.

FAQ

WHAT TYPE OF DATA CABLE IS REQUIRED FOR CONNECTION TO A SOLAR PANEL?

The type of data cable required for connecting to a solar panel varies based on the monitoring system and technology in use. Common options include twisted pair cables for RS485 communications or shielded Ethernet cables for more advanced setups. Careful consideration of the specific communication protocol supported by the solar panel is essential to ensure compatibility. Consulting the manufacturer’s documentation or specifications before selecting the cable type can prevent installation errors. Additionally, using high-quality cables helps to improve signal integrity and durability in outdoor environments. If in doubt, seeking expert advice can ensure that the correct data cable is chosen based on the unique configuration of the solar panel system.

HOW CAN I TEST WHETHER MY DATA CONNECTION IS WORKING PROPERLY?

Testing the data connection’s efficacy involves several methods to determine successful communication between the solar panel and the monitoring system. One such method includes using software tools to analyze data transmission directly, confirming whether performance metrics are being sent and received correctly. Observing live data through the monitoring interface provides immediate feedback on system status. Another approach involves utilizing multimeters or diagnostic tools to check voltage levels and signal integrity along the data line. Regular inspections of the physical connections, looking for signs of wear, damage, or loose fittings, also play a significant role in ensuring reliable communication. Documenting the tests performed and results obtained can provide invaluable insights for troubleshooting in the future.

WHAT ARE THE SAFETY PRECAUTIONS TO FOLLOW DURING INSTALLATION?

Ensuring safety during the installation of a data cable to a solar panel is critical for minimizing risks. Disengaging power sources before beginning the installation prevents electrical shock and protects all components involved. Wearing protective gear, such as gloves and goggles, helps safeguard against potential hazards. Inspecting tools and equipment beforehand is essential for identifying any faults or risks. Confirming the environment is clear of unnecessary obstructions and ensuring adequate lighting will enhance safety during the installation process. Additionally, following documented installation procedures and manufacturer guidelines can help avert unintended accidents or damage. It is prudent to enlist qualified professionals if unsure about safety protocols or required technical skills for the installation.

The process of connecting a data cable to a solar panel is a crucial undertaking, involving various considerations to ensure efficient operation and communication. By prioritizing safety, selecting the appropriate tools, and understanding the technical requirements of different solar panel systems, one can significantly enhance both performance and data reliability. Meticulously following each step, from preparation through maintenance, establishes a proactive approach towards the installation. Additionally, being equipped with knowledge of troubleshooting techniques is vital for swiftly addressing potential disruptions in communication. This comprehensive methodology not only serves as a roadmap for efficient implementation but creates a solid foundation for the longevity of the solar power installation. Recognizing the importance of ongoing maintenance and periodic assessments can support systems in delivering optimal performance throughout their lifespan. With the right approach and dedication, adventuring into the realm of solar energy can lead to considerable benefits, shaping a sustainable future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-data-cable-to-solar-panel/