To connect an angle valve and a solar tube, one must follow specific steps that ensure a secure and efficient setup. 1. Understanding the Components is crucial; both elements must be compatible for optimal performance. 2. Proper Installation Techniques are essential to avoid leaks; utilizing the right tools and methods enhances durability. 3. Regular Maintenance cannot be overlooked; this ensures longevity and functionality of the system. 4. Troubleshooting Common Issues will help in addressing potential problems early; being proactive prevents costly repairs.

By focusing on these aspects, one can effectively establish a reliable connection between the angle valve and the solar tube, leading to an operational solar heating system that maximizes efficiency and performance.

1. UNDERSTANDING THE COMPONENTS

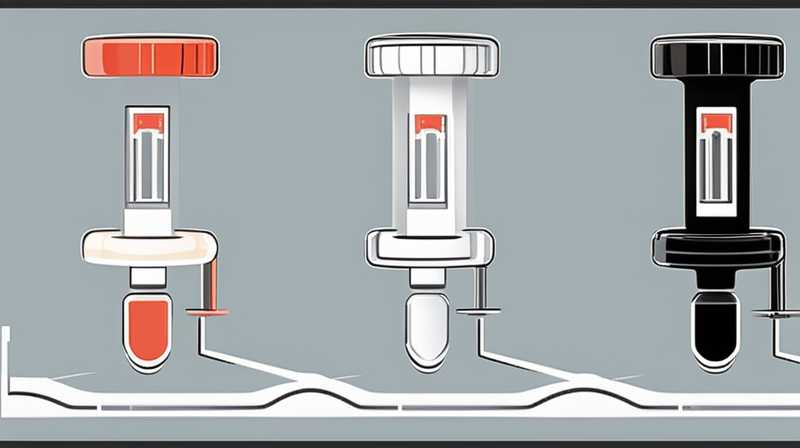

Connecting an angle valve and a solar tube begins with a clear comprehension of what each component entails. An angle valve acts as a control mechanism for fluid flow, typically integrating into a plumbing system welcoming various applications ranging from home heating to solar energy systems. Its design includes an inlet and outlet at a right angle, allowing for a streamlined connection to pipes. In the context of solar tube systems, they are cylindrical structures designed to capture solar energy and utilize it for heating water or air. The angle valve’s incorporation is critical in regulating this process effectively.

To create an efficient connection, it is vital that both the angle valve and the solar tube have compatible sizes and threading types. Most solar tubes utilize standard non-corrosive materials, which resist damage from prolonged exposure to water and sunlight. On the other hand, angle valves come in various materials, including brass, stainless steel, and plastic. Choosing the right material depends on the specifics of the installation site and the fluid being controlled. Ensuring compatibility not only aids in a seamless installation but also minimizes future maintenance challenges. Once familiarity with the elements is established, the next step involves determining installation requirements.

2. PROPER INSTALLATION TECHNIQUES

Embarking on the installation necessitates a strategic approach that guarantees security and efficiency. Initially, gather all required tools such as wrenches, Teflon tape, and pipe fittings. Prior to actual installation, inspect both the angle valve and the solar tube for any visible defects or malformations. Any imperfection can lead to complications down the line. Preparation also includes ensuring that the work environment is clean and free from obstructions, which increases safety and effectiveness.

Once ready, apply Teflon tape to the threaded ends of the angle valve and the solar tube. This helps provide a watertight seal, significantly reducing the risk of leaks. Begin by carefully threading the angle valve onto the solar tube, ensuring that the alignment is correct. Avoid overtightening, as this may lead to damaging the threading or compromising the valve’s structural integrity. After creating a snug fit, it’s advisable to use a wrench for a final secure twist. This process may differ slightly depending on the specific models being used, thus consulting the user manuals often proves beneficial.

Completing thorough connections ensures that there is a reliable passageway for fluid, leading to efficient operation.

3. REGULAR MAINTENANCE

Maintaining the system post-installation is paramount to ensure longevity and efficiency. Regular checks should include inspecting the angle valve and solar tube for any signs of wear, rust, or other forms of degradation. Given that both components are often exposed to fluctuating temperatures and environmental conditions, consistent monitoring will help in identifying issues early on. It is also wise to clean any debris or sediment that may accumulate around the fittings and valves. This not only maintains optimal performance but also prevents blockages that could hinder functionality.

In addition to visual inspections, performing routine operational tests is advisable. This can involve opening and closing the angle valve to ensure smooth operation. Moreover, checking the connections for any leaks should form part of the ongoing maintenance regime. Should any issues be discovered, employing immediate repairs will ensure minimal disruption to overall system performance. In the event of persistent problems, consulting with a professional plumber or technician specializing in solar systems can provide deeper insights and solutions, enhancing overall efficiency.

Furthermore, if necessary, consider upgrading components to more advanced models that offer improved performance or energy efficiency. Such investments may yield long-term cost savings on energy bills.

4. TROUBLESHOOTING COMMON ISSUES

Even with thorough installation and diligent maintenance, occasional issues may arise when connecting an angle valve with a solar tube. Recognizing common problems and understanding how to address them is vital. One frequent concern is water leakage at the joint where the angle valve meets the solar tube. This can occur due to insufficient sealing or improper tightening during installation. If detected, it is essential to turn off the water supply and disassemble the connection carefully to inspect the fittings. Reapplying Teflon tape or replacing worn washers may resolve the issue.

Another concern may be the angle valve’s failure to operate correctly, leading to inadequate control over fluid flow. This can happen due to internal blockages caused by debris or sediment buildup. In such cases, removing the valve for cleaning is recommended. Disassembling the angle valve provides access to its internal components, allowing for thorough cleaning and inspection. After ensuring all parts are free from obstructions and functioning properly, reassemble and test the connection to ensure fluid flows naturally.

Lastly, improper alignment during installation can cause strain on the joints, leading to misalignment of the entire system. This often manifests as rattling sounds or vibrations during operation. Careful realignment and resecuring of connections should correct any displacement, restoring normal function.

5. FREQUENTLY ASKED QUESTIONS

WHAT IS THE BEST MATERIAL FOR AN ANGLE VALVE IN SOLAR APPLICATIONS?

Selecting the appropriate material for an angle valve when dealing with solar applications is critical for durability and performance. Brass and stainless steel both emerge as top choices for several reasons. Brass benefits from excellent corrosion resistance, ensuring longevity even when exposed to moisture. This material is typically cost-effective and easy to source. However, when subjected to extreme heat, brass may weaken, which can become a concern during prolonged exposure to direct sunlight or high-temperature situations associated with solar installations.

Stainless steel, conversely, presents outstanding resistance to rust and extreme temperatures, making it an optimal choice for solar energy systems. Its robustness extends the lifespan of the angle valve, ensuring it can withstand significant fluctuations in environmental conditions. Although it may come at a higher price point initially, the long-term benefits often outweigh these costs. Ultimately, the best material depends on specific application requirements, including budget constraints and expected environmental factors.

HOW OFTEN SHOULD I MAINTAIN THE ANGLE VALVE AND SOLAR TUBE SYSTEM?

Determining the frequency of maintenance for an angle valve and solar tube system largely depends on usage patterns and environmental conditions. Ideally, a bi-annual check should be implemented for routine assessments. During such intervals, visually inspect for leaks, corrosion, and optimal functionality of both components, focusing particularly on the valve, as it regulates water flow directly.

However, if the solar heating system operates in areas that frequently experience harsh weather or high sediment levels in the water, more regular monitoring may be warranted. This includes quarterly inspections to ensure that debris does not impede the operation of your angle valve. Implementing a comprehensive maintenance schedule can reduce the probability of significant repairs and extend the overall longevity of the system. Always consult with a professional if abnormalities arise during your assessments to avoid potential costly alterations later.

WHAT ARE THE SIGNS THAT MY ANGLE VALVE IS MALFUNCTIONING?

Recognizing signs of malfunctioning angle valves can prevent major issues and ensure quick resolution. Common indicators include irregular flow rates, unusual noises, and visible leaks at the valve joints. If the valve fails to open or close properly, which may be characterized by the presence of resistance during manual operation, this suggests internal blockages or damage that requires immediate attention.

For those hearing hissing or banging noises, these often result from air trapped within the pipes or significant changes in pressure. These sounds could signify improper installation or existing system issues. Regularly checking for leaks around the joints is crucial, as this might indicate faulty seals or tightening that requires addressing. Ensuring these conditions are remedied in a timely fashion will maintain the integrity of the entire system.

In conclusion, establishing a successful connection between an angle valve and a solar tube is a multifaceted process that emphasizes diligent understanding, proper installation techniques, and regular maintenance. Each step has its unique importance, guiding individuals toward a comprehensive grasp of how these components function together to optimize the solar energy heating system. By being proactive in setup and future care, users can ensure prolonged efficiency and performance. Understanding crucial compatibility requirements, utilizing the right materials, and ensuring proper installation practices are essential foundational steps. Without these elements in place, even minor oversights may lead to significant complications down the line. This is further compounded by the importance of establishing a thorough maintenance regimen; frequent checks on your angle valve and solar tube’s condition can aid in early identification of potential issues, significantly saving on long-term costs. Engaging in proper troubleshooting techniques and understanding common problems will enhance one’s success in resolving issues swiftly and effectively. This multi-angle approach ultimately leads to a better-performing system with enhanced reliability. With careful attention to detail across all these stages, one can confidently navigate through the complexities of connecting an angle valve to a solar tube. Proper preparation, knowledge, and perseverance will result in a well-functioning solar heating system that delivers continuous benefits.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-angle-valve-and-solar-tube/