To effectively cleanse a solar drum, follow these steps: 1. Disconnect power, 2. Gather cleaning supplies, 3. Remove debris, 4. Clean surface, 5. Inspect components, 6. Reassemble and reconnect.

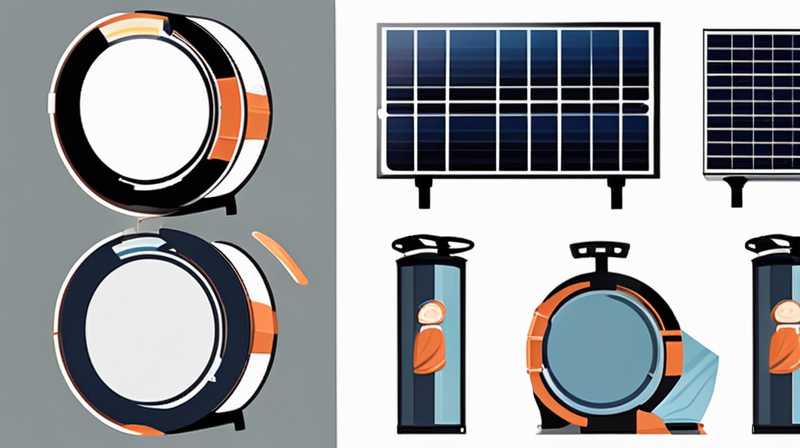

Cleaning the solar drum, a vital element in solar water heaters and other solar systems, involves meticulous attention to detail to ensure optimal performance. Maintenance is essential for maximizing energy efficiency and prolonging the lifespan of the unit. To achieve the best results, individuals should familiarize themselves with the equipment and materials required.

1. UNDERSTANDING THE COMPONENTS OF A SOLAR DRUM

A solar drum, integrated into solar thermal systems, operates primarily by collecting and transferring heat generated from sunlight. Understanding its components is crucial before initiating the cleaning process. The solar drum typically comprises a cylindrical body, end caps, internal coils, and sometimes, insulation layers. The drum’s material, often copper or steel, can influence the cleaning method employed.

The cylindrical design allows for an expansive surface area that maximizes the absorption of solar energy. Meanwhile, the internal coils facilitate the circulation of water or other heat-transfer fluids that distribute the captured heat efficiently. Each component plays a role in the effectiveness of the solar system, making it imperative to keep them clean and functioning optimally. Neglecting aspects such as debris build-up or contamination can lead to reduced heat transfer efficiency or even damage to the system.

2. IMPORTANCE OF REGULAR MAINTENANCE

Periodic maintenance and cleaning of the solar drum cannot be overstated. Various environmental factors contribute to the accumulation of dirt, dust, and other particles on the solar drum’s surface. These pollutants can obstruct sunlight absorption and impede the heating process, leading to diminished system performance.

In addition to performance degradation, neglecting regular cleaning can result in the corrosion of parts and a shorter lifespan of the solar system. The presence of contaminants, especially from the water used in the system, can lead to scale buildup inside the drum. This buildup can restrict water flow through the coils, thus hindering heat transfer efficiency. Therefore, staying proactive with maintenance can dramatically enhance performance and longevity.

3. GATHERING REQUIRED MATERIALS

Prior to undertaking the cleaning of a solar drum, it is essential to gather the right tools and materials. Key items needed for this task include: water, mild detergent, soft brush or sponge, cloths, gloves, goggles, and possibly a pressure washer for exterior cleaning.

Water is crucial for rinsing the drum and diluting any cleaning agents that may be used. Mild detergents, such as dish soap, soften grime without damaging the surface of the drum. Choosing the appropriate cleaning agent can help prevent corrosion and ensure that the drum remains intact. Meanwhile, soft brushes or sponges allow for effective cleaning without scratching the surface.

Safety should remain a priority during the cleaning process. Wearing gloves protects the hands from caustic solutions, and goggles shield the eyes from any splashes. It’s advisable to prepare a specific cleaning area to avoid contamination of surrounding space and to ensure an efficient and organized cleaning process.

4. DISCONNECTING THE SYSTEM

Before beginning the cleansing operation, disconnect the solar heating system from its power source. This essential step ensures safety while working on the unit and avoids accidental activation of any electrical components during the cleaning process.

Following power disconnection, allow any water in the system to cool down to a safe level. Working with heated water may result in burns or other injuries, making it imperative to allow adequate time for cooling. Disconnecting the water lines and removing any necessary panels or components to access the solar drum is necessary to perform a thorough cleaning.

Utilizing manufacturer guidelines can assist in determining the specific disassembly steps needed for each model. Properly documenting the disconnection process increases the likelihood of successful reassembly without any missing parts. This attention to detail sets a foundation for effective cleaning and maintenance.

5. REMOVING DEBRIS AND DIRT

Once access to the solar drum is achieved, the next phase involves removing any accumulated debris, dirt, or posters. Using a soft brush or vacuum cleaner, remove loose particles from the surface. This crucial step helps prevent scrubbing dirt into the surface, which could potentially scratch or damage the drum.

Debris often includes leaves, dust, and even insects that can gather on the exterior and surrounding areas of the solar drum. Following removal, visually inspecting for any particular problem spots is valuable. Watching for areas with exceptional build-up may signal deeper issues, such as leaks or component malfunction. Addressing these concerns before cleaning can further enhance the effectiveness of the entire maintenance practice.

6. CLEANING THE SURFACES

Using a mild detergent diluted in water, begin scrubbing the surfaces of the solar drum. The detergent should be applied using a soft brush or sponge, ensuring a gentle touch to avoid surface scratches. Focus attention on areas where dirt is concentrated and allow the cleaning solution to penetrate tough spots for a few minutes.

The internal components should also receive some attention. If accessible, the coils inside the drum can gather scale and sediment, which may need additional treatment. A vinegar solution or a specialized descaling agent targeted for plumbing can be employed carefully, ensuring any chemicals used are safe for the materials involved in the solar drum’s construction.

After washing, it is paramount to thoroughly rinse all surfaces with clean water. Thorough rinsing removes any detergent residue that may hinder future operations or introduce contaminants into the system later.

7. INSPECTING FOR WEAR AND TEAR

While the cleaning procedure is underway, take advantage of this opportune moment to inspect all parts of the solar drum. Look for signs of wear and tear, such as corrosion, cracks, or other anomalies that may necessitate repair or replacement.

Regular inspections can help identify potential issues early, minimizing the risk of system failure. When specific components show signs of wear, immediate action should be taken to address the problem, whether through repairs or consulting with a professional technician. Proactive measures can prevent escalating damage and maintain system efficiency.

Another essential aspect during inspection is ensuring that all connections, seals, and gaskets remain intact. Poor seals can lead to leaks, reducing the drum’s efficiency and potentially leading to significant water loss. Regular inspection and prompt repair of all interfaces can protect the system’s integrity.

8. REASSEMBLING THE SOLAR DRUM

Once the cleaning and inspection have been completed, the next step involves reassembling the system carefully. Begin by reinstalling any components that were removed during the disassembly process, ensuring that all seals and connections are secure and functioning.

It is crucial to refer to the manufacturer’s manual for specific instructions regarding reassembly. Attention to detail is necessary to prevent leaks or electrical faults when reconnecting the power supply. Additionally, double-check alignment and secure fittings appropriately to ensure optimal operation.

After reassembly, gradually restore power to the system and turn on the water lines. Observe the functionality of the system closely during this step, watching for any unusual sounds or leaks. Address any anomalies promptly by re-inspecting connections and components if necessary. Successful reassembly and testing mark a significant restorative measure ensuring the longevity of the solar drum.

9. ENFORCING A MAINTENANCE SCHEDULE

To maintain optimal performance, implementing a regular maintenance schedule proves beneficial. Routine checks can mitigate the buildup of debris and ensure the solar drum operates at peak efficiency.

The frequency of maintenance may depend on environmental factors, such as proximity to dust-prone areas or weather conditions that promote mildew. Some may find it beneficial to conduct a thorough clean annually, while others may opt for more frequent checks during the most demanding seasons.

Establishing reminders can ensure essential maintenance tasks do not slip through the cracks. Maintaining clear records of inspections, cleanings, and repairs can provide insight into performance trends over time and allow users to track potential issues before they escalate.

10. COMPLIANCE WITH SAFETY REGULATIONS

Taking safety seriously while working on solar systems is non-negotiable. Handling cleaning agents and tools can introduce hazards, thus, implementing strict safety protocols can protect individuals during the cleaning process.

Consider wearing protective gear, including gloves, goggles, and long sleeves to minimize exposure to harsh chemicals or sharp edges during clean up. Following manufacturers’ guidelines and safety standards is crucial in maintaining a safe working environment.

Training and preparation play a critical role in ensuring all individuals involved are fully aware of best practices, potential hazards, and the proper procedures required for effective solar drum cleaning. Compliance with safety regulations minimizes risk to both users and the surrounding environment.

FAQ 1: HOW OFTEN SHOULD I CLEAN MY SOLAR DRUM?

Determining how often to clean your solar drum hinges on your specific circumstances. Generally speaking, a comprehensive cleaning at least once a year is advisable. However, if your solar system experiences heavy usage or is in an area prone to dust or dirt accumulation, more frequent cleanings may be warranted.

Additionally, seasonal changes can affect cleaning frequency. In regions where dust and debris collect during certain times of the year, post-season cleanings may ensure optimum efficiency when the system is most needed. Always monitor the system’s performance; if you notice a decline in efficiency, inspecting and cleaning earlier than scheduled may prove necessary.

FAQ 2: WHAT DEBRIS CAN I EXPECT TO FIND?

Common debris collected on solar drums typically includes leaves, dust, dirt, and the occasional insect. In urban environments, pollution can also contribute to grime build-up on the drum’s surface. While many of these contaminants can often be removed using water and a mild detergent, persistent stains or mineral deposits may require additional treatment.

In isolated areas, entangling wildlife, such as plants or pollen, can also affect operation. Being mindful of your specific environment can aid in preparing for cleaning and ensuring that any unique considerations are addressed.

FAQ 3: WHAT ARE THE SIGNS OF A DIRTY SOLAR DRUM?

Observing the signs of a dirty solar drum can aid in maintaining your solar system’s efficiency. A common indicator includes reduced heating performance; if water takes longer to reach desired temperatures, the drum likely requires cleaning. A visible layer of dirt or debris on the surface and a cloudy water appearance may also signify cleanliness concerns.

Moreover, strange noises, unexpected pressure drop in water flow, or compromised structural integrity may suggest the presence of build-up or contamination inside the solar drum. Regular surveillance for these signs can inform timely action to restore system performance.

Maintaining and caring for a solar drum is an essential process that contributes significantly to the efficiency and effectiveness of the entire solar heating system. A structured approach emphasizing safety, cleanliness, and regular inspections proves invaluable not only for optimizing performance but also for ensuring the longevity of the drum. A meticulous cleaning process should incorporate the removal of debris, thorough rinsing, inspection, and routine maintenance to facilitate the systematic operation of a solar system. Implementing a tailored maintenance schedule ensures proactive measures are taken to uphold the overall functionality and reliability of the solar drum. By understanding the intricacies of the components and adhering to safety precautions, individuals can effectively retain the optimal working condition of the solar drum throughout its lifetime. This commitment to regular upkeep cultivates ongoing sustainability in solar energy utilization.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-clean-the-solar-drum/