To clean a solar thermal barrel, the following methods can be utilized: 1. Physical inspection and preparation of tools, 2. Using appropriate cleaning solutions, 3. Ensuring thorough rinsing of all residues, 4. Reassembly and check for leaks. An elaborate process involves a physical inspection of the barrel, which ensures that any visible debris or buildup is noted and addressed effectively. This initial step allows for a comprehensive understanding of the current condition of the equipment, paving the way for a successful cleaning operation.

1. UNDERSTANDING THE IMPORTANCE OF CLEANING

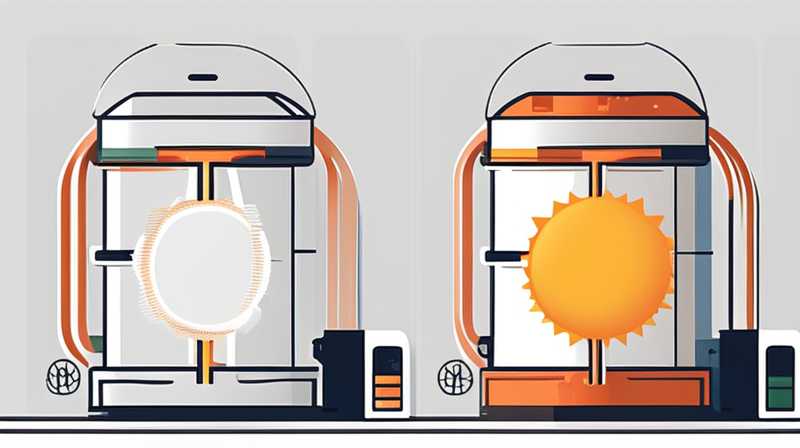

Maintaining the optimal performance of a solar thermal system is essential for reliable energy production. Solar thermal barrels, responsible for heating fluids, can accumulate debris over time, impairing efficiency. Regular cleaning not only enhances performance but also prolongs the lifespan of the equipment. A clean solar thermal barrel ensures better heat transfer and reduces the potential for corrosion and other reparative issues that might arise from stagnation of residue within the system.

Understanding the specific cleaning methods applicable to these barrels is crucial. Specialized cleaning agents can target mineral deposits, while certain methods ensure that any organic growth is effectively eliminated. The process is often technical but is imperative to ensure the system functions at peak efficiency. Moreover, cleaning procedures differ based on the environmental factors surrounding the system, making tailored approaches necessary.

2. PREPARATION FOR CLEANING

Before embarking on the cleaning of a solar thermal barrel, proper preparation is critical. One must gather the necessary tools such as brushes, cleaning solutions, hoses, and protective gear. The selection of cleaning agents is particularly significant. Many manufacturers recommend environmentally friendly options that avoid harsh chemicals to prevent damage to the barrel or the surrounding environment. Ensuring that the tools are appropriate for the job is essential for avoiding unnecessary damage during the cleaning process.

Moreover, preparing the work environment is just as vital. Ensure that areas around the solar thermal barrel are accessible, organized, and clean to avoid introducing further contaminants during the cleaning process. Always turn off any connections to the system and safely disconnect it from other components. This preparation phase can significantly reduce the risk of accidents and ensure a smooth cleaning operation, setting a strong foundation for effective procedures.

3. EXECUTION OF CLEANING PROCEDURES

Following adequate preparation, the next step involves executing the cleaning procedures. 1. Physical inspection should precede any chemical interactions. Visibly assess the barrel for accessibility to sediments or build-up that may require more specialized attention. In many cases, a simple mechanical cleaning with a soft brush can help dislodge stubborn deposits without causing abrasions. Utilizing non-abrasive tools is necessary to maintain the integrity of the barrel’s protective coatings.

2. Applying cleaning solutions is the next crucial action. Soaking time varies, and adherence to manufacturer guidelines is necessary for effectiveness. Pouring the cleaning solution into the barrel and allowing it to sit creates a reaction that breaks down mineral deposits or other buildups aiding in their removal. Utilizing a pump to circulate the cleaning solution can enhance the process, ensuring that every area is treated before rinsing.

4. RINSING AND REASSEMBLY

Upon completion of the chemical cleaning, proper rinsing procedures follow. This step is vital to ensure that no cleaning agents remain in the system. Running clean water through the system helps to flush out residue, which can be verified by monitoring the outflow clarity over time. Ensuring a comprehensive rinse should not be underestimated, as lingering solutions can lead to corrosion or other harmful effects, eventually undermining the system’s functionality.

Reassembly and leak checks are always the concluding steps in the cleaning process. Once the barrel has been thoroughly cleaned and rinsed, it can be reassembled carefully. Carefully reconnect all fittings and components, ensuring secure seals to prevent any leaks once the system is reactivated. A thorough check around the joints and connections for any signs of leakage is a necessary precautionary measure. Regular checks post-cleaning can also ensure that the system remains free from contamination and operates efficiently.

FAQs

WHAT ARE THE SIGNS THAT A SOLAR THERMAL BARREL NEEDS CLEANING?

Recognizing when a solar thermal barrel requires cleaning involves identifying several indicators. 1. Diminished heat output is one major sign; when the system fails to heat fluids effectively, it may point to buildup inside the barrel. Additionally, 2. Visible sediment within the system is an overt indication that cleaning is necessary. Clogged filters or a substantial drop in fluid flow might also suggest that the barrel requires attention. Finally, 3. Unusual noises from the system can indicate disruptions caused by debris obstructing usual fluid paths, necessitating a thorough evaluation and cleaning procedure.

CAN I USE HARSH CHEMICALS TO CLEAN MY SOLAR THERMAL BARREL?

While it may be tempting to opt for harsh chemicals to facilitate the cleaning process, exercising caution is paramount. 1. Potential damage to the barrel and its components must be considered; strong acids or bases can degrade protective coatings and even the structural material of the barrel. Furthermore, 2. Environmental impacts must be addressed, as harsh chemicals can contaminate surrounding soil or water supplies detrimental to the ecosystem. Opting for mild, biodegradable cleaners specifically designed for solar thermal systems ensures both effectiveness and safety, yielding a successful cleaning without harming the barrel.

HOW OFTEN SHOULD MY SOLAR THERMAL BARREL BE CLEANED?

The frequency of cleaning a solar thermal barrel can vary based on 1. System usage and environmental factors. In general, a routine inspection at least twice a year is advisable for optimal performance. Systems located in harsh climates may require more frequent attention, as dust, debris, and mineral buildup can occur at an accelerated rate. Additionally, 2. Performance monitoring offers insights into cleaning schedules; if noticeable efficiency drops are observed, an immediate cleaning might be necessary to restore effectiveness. Developing a proactive maintenance routine ensures longevity and efficiency in solar thermal systems.

In summarizing the process of cleaning a solar thermal barrel, understanding the significance of rigorous maintenance is crucial. Regular cleaning enhances efficiency and extends lifespan; therefore, gathering suitable tools and preparing thoroughly initiates a successful cleaning journey. Each procedure must be executed attentively, ensuring safety and effectiveness. Particularly important is rinsing and the final reconstruction of the system while checking for any potential leaks, which guarantees continued operational integrity. Ultimately, maintaining solar thermal barrels will yield significant returns on investments in both energy savings and system reliability, making it integral to the upkeep of a solar thermal system. By adhering to recommended cleaning practices, individuals can assure the performance of their systems, reaping the benefits of sustainable energy solutions for many years.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-clean-a-solar-thermal-barrel/