To classify the quality of solar solenoid valves, several critical parameters must be assessed, including 1. material composition, 2. performance specifications, 3. operational durability, and 4. manufacturer reputation. Material composition refers to the substances used to produce the valves, as these affect their resilience to environmental factors. Performance specifications involve evaluating the valve’s flow rate, pressure rating, and response times, which are vital for ensuring effective functioning in solar applications. Operational durability must be rigorously tested to ascertain the expected lifespan under real-world conditions. Finally, the reputation of the manufacturer plays an essential role in determining quality, as established brands often exhibit more consistent quality standards based on extensive industry experience and customer feedback.

MATERIAL COMPOSITION

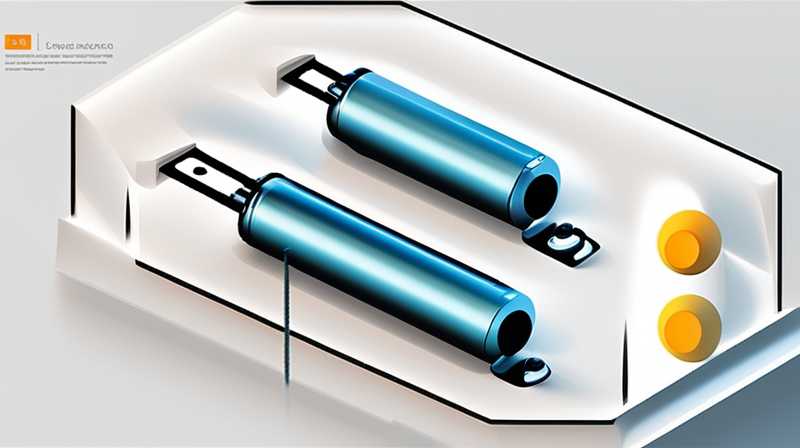

The essence of solar solenoid valves hinges on their material composition, which significantly impacts their resilience and overall functionality. These valves are often exposed to challenging elements such as UV radiation, humidity, and temperature fluctuations. High-quality materials are essential for preventing degradation over time. For instance, brass, stainless steel, and specialized polymers are among the notable materials used in manufacturing these components.

Brass valves are esteemed for their corrosion resistance and robustness but may not perform optimally in highly corrosive environments. Conversely, stainless steel valves offer superior resistance to corrosion and high-temperature conditions, making them highly suitable for applications in harsher environments. Polymers, while lightweight and resistant to corrosion, may lack the operational longevity under extreme pressure scenarios.

Beyond mere selection, the manufacturing process defines how well these materials perform. Methods such as forging and machining can enhance the longevity and reliability of valve components. The thickness of the material and internal coatings also play a role. Coatings that resist corrosion can extend the life of solenoid valves exponentially, thus maximizing investment returns in solar applications.

PERFORMANCE SPECIFICATIONS

The performance specifications of solar solenoid valves dictate how efficiently and reliably they operate within solar-powered systems. Key parameters include flow rate, pressure rating, and actuation speed. The flow rate is determined by how quickly fluid can pass through the valve when activated, which has direct implications for the efficiency of the solar system. If the flow rate is inadequate, it could hinder the entire solar setup’s performance.

A valve’s pressure rating indicates the maximum pressure it can sustain without failure. This characteristic is paramount because solar applications may experience varying pressures, especially in systems where there is a considerable fluctuation in liquid temperatures. A robust pressure rating ensures continuous functionality even under fluctuating operational conditions. Moreover, evaluating the actuation speed is critical; solenoid valves must respond swiftly to changes in system demand. A lag in response can lead to operational inefficiencies, ultimately affecting the solar system’s overall performance.

Another integral aspect is the energy consumption of the solenoid valve. Given that these valves are often powered by solar energy, selecting low-power solenoids can enhance the sustainability of the entire system. Valve designs that enable quick activation while minimizing energy draw are preferable, as they can help in maintaining the balance of the overall solar energy usage.

OPERATIONAL DURABILITY

Understanding operational durability is vital for predicting a solar solenoid valve’s lifespan and reliability over time. The term encapsulates several aspects, including resistance to fatigue, thermal stability, and resilience against environmental factors. Solar installations often face extreme weather situations, and components must withstand not just pressure, but also other challenges such as moisture, dust, and temperature variations.

Choosing solenoid valves constructed with high-quality seals and gaskets is critical as they prevent leakage and maintain operational efficacy. Regular exposure to rain, dirt, and other environmental challenges can break down subpar rubber or plastic materials leading to deterioration. Additionally, valves should undergo rigorous testing standards such as those set by ASTM (American Society for Testing and Materials) to ensure their capability to function effectively over their anticipated lifespan.

Moreover, it can be beneficial to look into warranty periods and service agreements offered by manufacturers. Companies that demonstrate confidence in their products often provide extensive warranties, reflecting the durability standards met during production. Evaluating what testing has been done on the valves can significantly inform decisions on quality.

MANUFACTURER REPUTATION

The reputation of the manufacturer plays a crucial role when classifying the quality of solar solenoid valves. Companies that specialize in solenoid technology and have extensive experience in solar applications typically provide products that have been proven over time. It is valuable to examine the history and customer feedback associated with a manufacturer. Testimonials and product reviews can offer insights into reliability and performance in practical scenarios.

In addition, manufacturers that adhere to international standards such as ISO certification tend to have more rigorous quality control processes in place. This certification provides an assurance that the products are manufactured under strict quality assurance systems, helping to mitigate the risk of purchasing inferior valves. Engaging with industry forums and user communities can also provide anecdotal evidence regarding the real-world performance of products, aiding potential buyers in making informed decisions.

Trade shows and exhibitions often showcase newer technologies and innovations introduced by various manufacturers, providing an excellent opportunity to examine products firsthand. Such events allow attendees to ask questions, gain first-hand knowledge, and understand the offerings in greater detail. Investigating a manufacturer’s capacity for research and development can also be beneficial for assessing long-term viability and their commitment to evolving technology.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE KEY FACTORS AFFECTING THE QUALITY OF SOLENOID VALVES?

Several vital factors influence the quality of solenoid valves in solar applications. Material composition is paramount, as it determines resistance to corrosion and environmental wear. Valves made from stainless steel or high-performance polymers usually outperform standard materials. Performance specifications, including flow rate, pressure rating, and actuation speed, are crucial; a well-rated valve will operate effectively under varying conditions. Also, operational durability plays a significant role; high-quality seals and durable materials ensure longevity under challenging environmental conditions. Lastly, investigating the manufacturer’s reputation is essential. Established brands often provide reliable warranties and customer service, ensuring customers receive components that meet or exceed expectations.

HOW CAN I DETERMINE THE APPROPRIATE SOLENOID VALVE FOR MY SOLAR SYSTEM?

Selecting the appropriate solenoid valve for a solar system hinges on several critical measures. First, assess your specific requirements—what is the necessary flow rate and pressure rating for your application? Analyze your system’s characteristics to ensure compatibility within the solar framework. Investigate the environmental conditions the valve will face, as this can dictate the material and design you should choose. Typically, stainless steel offers superior resistance to moisture and temperature fluctuations but may be overkill in less demanding conditions.

Moreover, consider the space constraints and installation methodology, ensuring the valve fits seamlessly within your setup. Finally, always look to verify the manufacturer’s specifications and gather peer reviews. This approach ensures you’re not only meeting immediate needs but also investing in durability and efficiency for the long term.

WHAT ARE THE COMMON MISTAKES TO AVOID WHEN CHOOSING SOLENOID VALVES?

Mistakes in selecting solenoid valves can lead to inefficiencies and unnecessary expenses. One common error is underestimating the effect of environmental conditions; opting for low-cost materials can lead to premature failure. Ensuring the valve can withstand humidity, temperature shifts, and UV exposure is crucial to maintaining longevity. Also, it is vital to consider incorrect sizing. A valve that is too small may restrict flow, while one that is too large can lead to inefficiencies and increase energy consumption.

Focusing solely on price is another pitfall; selecting the cheapest option often sacrifices quality and durability. Consider the long-term investment value of a higher-quality product, which, in most cases, pays off through lesser maintenance needs and enhanced performance. Moreover, neglecting review data and the manufacturer’s reputation can be detrimental. Always prioritize brands known for quality and customer satisfaction.

In sum, assessing the quality of solar solenoid valves requires a multifaceted approach focusing on material composition, performance specifications, operational durability, and manufacturer reputation. These dimensions interact to influence the overall effectiveness of valves within solar energy systems, providing insights into their long-lasting value and reliability. Carefully selecting components ensures that the solar system operates efficiently, withstands adverse conditions, and delivers significant returns on investment. A rigorous evaluation based on these parameters fosters informed decisions, reducing the risk of operational inefficiencies and component failure. Whether through materials offering superior resistance or performance guarantees established by reputable manufacturers, investing time in understanding solenoid valves shapes a reliable groundwork for successful solar energy applications. With a thorough assessment, users can confidently ensure their systems achieve their fullest potential while granting sustainability in the long run.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-classify-the-quality-of-solar-solenoid-valves/