1. Understanding Solar Valve Models Can Be Complicated, 2. Classification Is Essential for System Efficiency, 3. Various Factors Play a Role in This Classification, 4. Specific Models Have Distinct Features That Impact Performance

In the realm of solar energy systems, the classification of solar valve models is pivotal for maintaining efficiency and ensuring optimal performance. 1. The first step involves understanding the function of solar valves, which primarily regulate the flow of heat transfer fluids in solar thermal applications, thus maximizing energy capture and minimizing losses. 2. The second aspect concerns the technological variations across models, such as their design considerations, material compositions, and the applications for which they are best suited. 3. Moreover, the distinctions between automatic and manual operation styles should also be noted since they cater to different user needs and installation environments. 4. Ultimately, successful classification of solar valves hinges on comprehensively considering these components, allowing for informed decisions when selecting the appropriate valve for specific solar heating setups.

CLASSIFICATION CRITERIA OF SOLAR VALVES

Understanding Valve Functions

In solar thermal systems, valves serve as critical components for maintaining fluid movement and temperature regulation. A solar valve’s primary function is to control the flow of heat transfer fluids, which may include water or specialized solar fluids, depending on the system design. This control is vital for optimizing energy collection during various operational conditions, such as fluctuating solar irradiance or changes in the heat demands of connected systems. They can be categorized into several types based on their operational principles. For example, two-way valves allow for fluid to circulate in either direction, while three-way valves can divert flow between two directions, adjusting to the heat demand of the system more effectively.

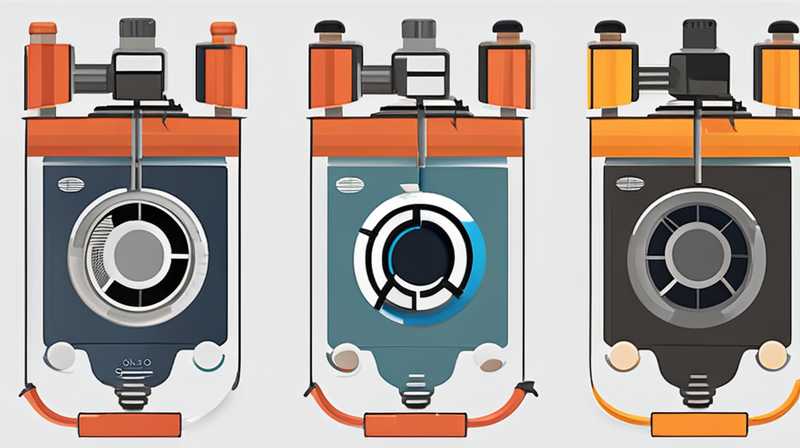

Mechanical Sense Versus Electronic Control

Another way to classify solar valves is based on their operational mechanisms. Mechanical valves operate using temperature-sensitive materials or pressure-responsive designs that react to the fluid’s thermal characteristics. These systems are typically characterized by their simplicity and durability, making them suitable for a wide range of applications where high precision is not as critical. In contrast, electronic or electrically actuated valves provide precise control of fluid movement, using sensors and actuators. This sophisticated approach allows for greater accuracy in maintaining set temperatures and can significantly enhance system performance, especially in larger, more complex installations.

MATERIALS AND DESIGN INFLUENCING CLASSIFICATION

Common Materials Used in Solar Valve Construction

The materials used to manufacture solar valves also play a significant role in their classification. Brass and stainless steel are among the most widely utilized materials for valve bodies, due to their excellent corrosion resistance and durability in outdoor conditions. These materials ensure that the valves can withstand the varying temperatures and pressures present in solar thermal systems. In some instances, polymers and composite materials are employed, especially in applications where weight savings are a primary design consideration. These alternatives, while less common, can offer sufficient durability in less extreme environments.

Thermal Conductivity and Insulation Features

Beyond mere construction materials, the design features of solar valves impact their performance and classification. Valves with advanced thermal insulation features can minimize heat loss, which is particularly crucial in colder climates. Design considerations such as sealing techniques and flow paths can significantly influence how effectively a valve operates within a solar system. Properly designed valves can ensure that fluids circulate efficiently, reducing wear on moving parts and prolonging system life while reducing energy losses resulting from inefficient flow dynamics.

TYPES OF SOLAR VALVE APPLICATIONS

Residential Solar Heating Systems

In residential applications, solar valves are often employed in systems such as solar water heaters or space heating solutions. In these contexts, two-way and three-way valves are typically utilized to efficiently manage the flow of heated water or glycol solutions between collectors and storage units. Control strategies in these systems may be simpler, as the objective is primarily to provide comfortable heating levels with manageable installation costs.

Commercial Applications and District Heating

Larger setups, such as commercial systems or district heating operations, often employ more sophisticated valve arrangements. In these cases, electronic valves become more common due to their enhanced control capabilities, enabling better load balancing and energy management across extensive and diverse heating demands. A combination of different valve types can be seen in these larger systems, where multiple zones need independent control, ensuring optimal performance across the entire network.

SETUP AND MAINTENANCE CONSIDERATIONS

Installation Procedures

The classification of solar valves must also take into account their installation requirements. Some valves are designed for straightforward plug-and-play installation, intended for quick setups without extensive modifications to existing systems. Others may require more detailed installation procedures, involving piping alterations or specific mounting techniques, making them less favorable for DIY enthusiasts. Proper valve placement is critical, as incorrect installations can lead to significant inefficiencies and potential system failures.

Maintaining Longevity and Efficiency

Maintenance is another consideration for classification, with some valves requiring regular checks and servicing to ensure they function optimally. Mechanical valves, for instance, may need to be calibrated and cleaned periodically to prevent build-up of scale or debris. As a general rule, the more complex the valve mechanism, the more detailed the maintenance schedule should be. Establishing clear maintenance protocols can help extend the operational lifespan of solar valves, ultimately affecting the overall sustainability of the solar energy system.

ECONOMIC IMPACT OF SOLAR VALVE CLASSIFICATION

Cost Considerations

The economic aspects surrounding the classification of solar valves are a substantial concern for installers and end-users alike. The initial investment in high-quality valves can yield significant long-term savings. For instance, selecting advanced electronic valves may be costly upfront; however, they can reduce energy wastage and enhance overall system performance, thereby providing financial returns over time. Conversely, opting for less sophisticated models may lead to higher operational costs due to inefficiencies.

Impact on System Efficiency and Reliability

Beyond direct costs, the classification of solar valves affects system efficiency and reliability, as previously mentioned. Efficient systems reduce energy consumption and provide better returns on investment over the system’s lifetime, leading to substantial savings for the user. Valves that fail to perform as expected can cause not just energy losses but also lead to mechanical failures in connected equipment, further amplifying the financial impact of poor valve selections.

FREQUENTLY ASKED QUESTIONS

HOW DO I CHOOSE THE RIGHT SOLAR VALVE MODEL?

Selecting the appropriate solar valve model requires a thorough understanding of the specific application and the system design. Considerations include the type of solar thermal system being utilized, the operational requirements, and the thermal characteristics of the fluid involved. Assessing the technical specifications and compatibility with existing components is essential. Consulting with manufacturers or experienced installers is also advisable, as they often have insights into the best practices for specific installations. Ultimately, it’s imperative to ensure that the chosen valve meets the required efficiency standards and offers durability for the expected environmental conditions.

WHAT ARE THE BENEFITS OF USING ELECTRONIC SOLAR VALVES?

Electronic solar valves offer a multitude of advantages compared to traditional mechanical counterparts. Primarily, they provide enhanced precision in flow control, allowing for more tailored temperature regulation within the system. This capability can lead to significant energy efficiency improvements since they react to real-time data. Additionally, electronic valves often feature integration with smart home systems, providing greater automation and ease of use. While the initial costs can be higher, the long-term savings through improved efficiency and reduced maintenance make them an attractive option for many users.

HOW OFTEN DO SOLAR VALVES NEED MAINTENANCE?

Regular maintenance ensures that solar valves operate optimally throughout their lifespan. For mechanical models, checking and cleaning components should be performed annually, while more sophisticated electronic valves may necessitate inspections less frequently, depending on usage. It is critical to consult the manufacturer’s guidelines for precise maintenance intervals. Performing routine maintenance not only extends the life of the valves but also maintains the overall efficiency and reliability of the solar thermal system, reducing the risk of more extensive and costly repairs down the line.

SIGNIFICANCE OF PROPER CLASSIFICATION IN SOLAR VALVES

Careful classification of solar valve models is imperative for optimizing energy gains from solar thermal systems. Each model possesses unique characteristics, operational features, and interaction dynamics with other system components. By understanding the nuances within this classification, installers can make well-informed decisions that enhance efficiency and system reliability. This comprehensive approach ultimately supports sustainable energy practices, critical in the ever-evolving landscape of renewable energy technologies.

In summary, mastering the classification of solar valve models empowers stakeholders to enhance system performance. Choosing the right valve based on functional, material, and application-based criteria fosters a better understanding of solar technology capabilities. Ultimately, this knowledge contributes to developing more efficient solar heating solutions, aligning perfectly with the goals of sustainability and energy conservation. The continual advancement in solar technologies further emphasizes the need for careful consideration of valve selection, underscoring the importance of thorough research and expertise in the field.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-classify-solar-valve-models/