Choosing a solar thermal insulation barrel for engineering involves several key considerations: 1. Assessing the thermal performance, 2. Evaluating material durability, 3. Determining the size and capacity requirements, 4. Analyzing the installation method. Each of these aspects plays a crucial role in ensuring that the selected barrel effectively harnesses solar energy, minimizes heat loss, and meets the engineering project’s specific demands.

1. ASSESSING THERMAL PERFORMANCE

Thermal performance serves as the foremost consideration when selecting a solar thermal insulation barrel. The efficiency with which a barrel can retain heat directly influences energy conservation and overall system efficacy. Major factors that impact thermal performance include the insulation material’s R-value and the design of the barrel itself. R-value measures the insulation’s resistance to heat flow; a higher R-value indicates better insulation. Common materials such as polyurethane, polystyrene, and fiberglass each possess distinct R-values and thermal properties that should align with project demands.

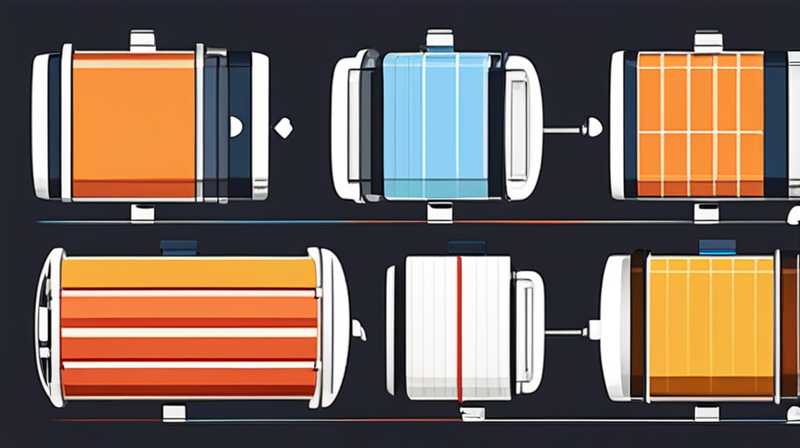

In addition, the geometry of the barrel can significantly affect thermal performance. Cylindrical shapes, for instance, tend to reduce heat loss due to less surface area exposed to the environment than flat surfaces. Selecting a barrel with optimal geometry can greatly enhance heat retention and consequently improve the system’s efficiency. Furthermore, consider the environmental factors that may impact thermal performance: shading from nearby structures, typical weather conditions, and the geographic location should influence the type of barrel that is most suitable.

2. EVALUATING MATERIAL DURABILITY

Durability of materials used in manufacturing the insulation barrel is another essential factor to consider. Barrels exposed to outdoor conditions must withstand various climatic challenges such as UV radiation, moisture, and temperature fluctuations. Materials like high-density polyethylene or stainless steel are often preferred for their resistance to corrosion and UV degradation. When assessing durability, understanding the environmental conditions in which the insulation barrel will operate is crucial, as regulation standards may vary based on geographic regions.

Moreover, prolonged exposure to extreme conditions can degrade performance over time. Conducting a life-cycle analysis will provide insight into the long-term viability of the materials under consideration. This analysis should include not only the expected lifespan of the insulation material but also the maintenance requirements and potential repair modalities. Investing in durable materials initially can reduce costs and prevent system failures, thereby ensuring the project’s reliability and performance over time.

3. DETERMINING SIZE AND CAPACITY REQUIREMENTS

Determining the appropriate size and capacity configuration for a solar thermal insulation barrel is critical in achieving desired outcomes. Capacity must align with the thermal needs of the system being implemented, which can vary extensively depending on the specific application. For instance, residential applications may necessitate barrels of smaller capacity compared to commercial installations, where significant heat retention is required.

When selecting size, consideration must also be given to available space for installation and the overarching system design. Overly bulky barrels can hinder efficiency by making maintenance challenging or occupying valuable real estate. To make informed decisions, engineers should calculate the anticipated energy load and select a barrel that meets, but does not excessively surpass, this requirement.

4. ANALYZING INSTALLATION METHOD

The method of installation can have significant implications on the performance and efficiency of solar thermal barrels. Assessing the complexity and practical aspects of installation is essential for proper integration into existing systems. Different installation methods may exist, including direct mounting solutions versus rack-mounted systems, each with its own advantages and limitations.

Furthermore, installation requirements should encompass connectivity with related thermal systems. Proper piping, insulation, and integration with existing energy systems must be planned carefully to ensure seamless operation. Engineers must also consider future needs and whether the insulation barrel design accommodates potential system expansions or modifications. A well-planned installation that allows for flexibility can facilitate system upgrades in the long run, optimizing energy yields and system performance.

FAQs

WHAT MATERIALS ARE BEST FOR SOLAR THERMAL INSULATION BARRELS?

The materials ideal for solar thermal insulation barrels include polyurethane, polystyrene, and fiberglass. Each of these materials offers a unique R-value, impacting how well they retain heat. Polyurethane, for instance, boasts one of the highest insulating values, making it suitable for areas with significant temperature variations. Polystyrene is often favored for its cost-effectiveness and lightweight properties, while fiberglass is known for its resilience in high moisture situations. The best choice depends on the specific environmental conditions and energy requirements of the project.

HOW DO YOU DETERMINE THE OPTIMAL SIZE OF A SOLAR THERMAL INSULATION BARREL?

To determine the optimal size of a solar thermal insulation barrel, one must analyze the energy demands of the system it will support. The energy load calculations should factor in the intended use, ambient temperature fluctuations, and heat loss potential. A detailed assessment of both historical and projected energy consumption will provide a guideline for capacity requirements. Furthermore, consideration of available installation space must also be taken into account to ensure the barrel fits within the designated area while still providing adequate thermal capacity.

WHAT ARE THE COMMON INSTALLATION CHALLENGES WITH SOLAR THERMAL INSULATION BARRELS?

Common challenges encountered during the installation of solar thermal insulation barrels include hydraulic connections, ensuring airtight seals, and alignment with existing systems. Maintaining efficiency involves precision during installation; any leaks can lead to substantial energy losses. Additionally, installers must navigate spatial constraints, ensuring that the barrel is accessible for future maintenance while still placed in a position that maximizes energy absorption. A meticulous plan that anticipates potential hurdles can mitigate these challenges, thereby greatly enhancing installation success.

The selection process for a solar thermal insulation barrel is a multifaceted endeavor, comprising various critical aspects that must be meticulously examined. Evaluating thermal performance is paramount, as the barrel serves to harness and retain solar energy efficiently. Subsequently, the durability of materials must be considered to ensure resilience in diverse environmental conditions, maintaining performance over time. Correctly determining the size and capacity facilitates optimal energy loads without wasting space or resources. Moreover, understanding installation methods is essential for integration and future scalability.

In respect to all these elements, a comprehensive approach ensures efficient functionality of the insulation barrel while maximizing overall energy savings for the engineering project. Adequately addressing these areas during the selection process will not only enhance the immediate performance of the thermal insulation barrel but also foster long-term reliability and cost-efficiency. Such foresight and diligence in selecting the appropriate solar thermal insulation barrel ultimately contribute to the sustainability of engineering projects aimed at utilizing renewable energy resources.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-choose-solar-thermal-insulation-barrel-for-engineering/