1. Understanding the Types of Solar Solenoid Valves, 2. Assessing Pressure Requirements, 3. Evaluating Durability and Material, 4. Considering Control Mechanisms, 5. Budgeting and Cost Considerations

In selecting an appropriate solar solenoid valve, several factors must be weighed carefully. 1. The identification of the specific types of solar solenoid valves available is crucial. Newcomers to the field may not grasp the distinctions among models and how they cater to different systems. 2. Assessing the pressure requirements is paramount. Each application necessitates varying pressure levels, and understanding the specific needs of the system will prevent difficulties later. 3. Evaluating the durability and material of the valve ensures longevity. High-quality materials withstand wear and tear, especially in outdoor settings. 4. Considering control mechanisms is essential for efficient operation. Options range from manual to automated systems, and the intended use will dictate the best choice. 5. Budgeting is key to a successful acquisition. Understand that investing in a quality valve might incur initial costs, but it ultimately saves money through efficiency and reduced maintenance.

1. UNDERSTANDING THE TYPES OF SOLAR SOLENOID VALVES

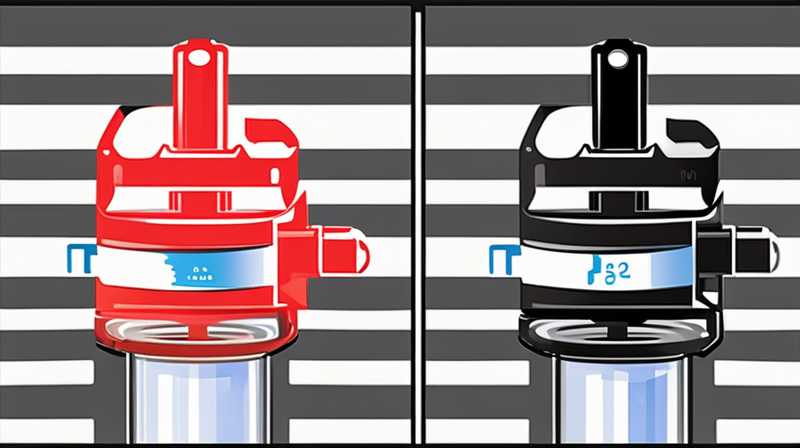

Solar solenoid valves come in a variety of shapes and functionalities, catering to different requirements in solar-powered irrigation, heating systems, and hydroponics. Recognizing the available types is significant in selecting the most suitable model for specific applications. Generally, two primary variants exist: normally closed and normally open solenoid valves. Normally closed valves remain in a shut position until air pressure or electronic actuation opens them, making them ideal for preventing undesired flow when the system is inactive. Conversely, normally open valves allow flow until the energizing force closes them, making them useful for applications requiring constant flow until a specific action is triggered.

The choice between these two types greatly affects system design. In irrigation applications, for instance, utilizing normally closed valves permits water to be available where needed only when the system is actively watering, thus conserving resources. In contrast, when constant circulation is required, normally open options are preferable. Beyond these, numerous manufacturers introduce variations designed for specific applications, such as anti-drain valves or backflow preventers, offering additional layers of control and security. Therefore, weighing these characteristics is essential in making an informed decision.

2. ASSESSING PRESSURE REQUIREMENTS

Pressure requirements are intrinsic elements that dictate valve compatibility within a solar application. Various systems operate at distinct pressure levels, and understanding the operational demands is crucial. Typically, valves are rated according to their maximum allowable pressure, and selecting a valve that can handle the intended system pressure without exceeding its limits is imperative. Failing to choose correctly can result in leaks or premature failure, leading to a waste of time and resources to address these issues later.

It’s paramount to assess both static and dynamic pressures within the application. Static pressure can be measured when the fluid is undisturbed, while dynamic pressure occurs when the fluid is flowing. Correct valve selection necessitates consideration of these variables, especially in environments with fluctuating pressures where valve performance may be compromised if not appropriately matched. Additionally, environmental conditions, such as temperature fluctuations or exposure to corrosive elements, can affect pressure levels and, thus, valve performance. Therefore, a meticulous evaluation of all pressure aspects is necessary to ensure successful operation.

3. EVALUATING DURABILITY AND MATERIAL

Durability is directly linked to the materials used in constructing solar solenoid valves. Selecting valves constructed from high-quality materials will extend their life cycle, providing reliable service even under harsh environmental conditions. Common materials include brass, stainless steel, and plastic. Each has its set of advantages; for example, brass offers excellent toughness and resistance to corrosion, while plastic valves can be lightweight and cost-effective.

An understanding of the application’s geographic location is vital in assessing material suitability. For instance, regions with extreme weather conditions may require more resilient materials, such as stainless steel, which stands up well to corrosion caused by humidity or exposure to aggressive chemicals. Additionally, other environmental factors can influence material choice; UV exposure in sunny environments may necessitate light-resistant plastics or coatings to prevent degradation over time. Thus, careful evaluation of the application’s demands alongside material properties is critical to ensure the longevity and efficiency of the solar solenoid valve.

4. CONSIDERING CONTROL MECHANISMS

Control mechanisms significantly impact the performance and efficiency of solar solenoid valves. Different systems utilize various methods to actuate valves, ranging from manual operations to fully automated setups controlled by timers or sensors. For instance, in agricultural applications, automated irrigation systems use sensors that detect soil moisture levels, triggering solenoid valves to open only when needed. This helps to conserve water and optimize plant growth conditions.

In contrast, manual valves can be advantageous for smaller systems where automation may be unnecessary. Such simplicity can offer ease of installation and reduced complexity, although it may require more labor input to operate. Understanding the specific requirements of the application in question will guide the selection of control systems. Advanced technology has even paved the way for smart solenoid valves that can integrate with IoT devices, providing real-time tracking and control from remote locations. Thus, the choice of control mechanisms plays a vital role in achieving an efficient system.

5. BUDGETING AND COST CONSIDERATIONS

Budgeting holds a pivotal role in successfully acquiring solar solenoid valves. An understanding of initial costs, ongoing expenses, and projected long-term savings is necessary for making informed financial decisions. When considering initial costs, it is vital to remember that cheaper options might seem appealing, but long-term functionality should not be overlooked. Investing in a quality valve may involve higher upfront costs but could lead to substantial savings on maintenance and replacements.

Operating costs must also be factored into the overall budgeting process. These may encompass energy consumption for automated systems, potential repairs, and even costs related to downtime caused by valve failures. A comprehensive assessment of potential costs ensures that funds are allocated efficiently while preventing unexpected expenses in the future. Furthermore, incentives, rebates, or grants may be available for using energy-efficient technologies, providing additional financial relief. Consequently, a well-planned budget that encompasses both immediate and ongoing costs will facilitate better financial outcomes.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE DIFFERENT TYPES OF SOLAR SOLENOID VALVES?

Solar solenoid valves primarily fall into two categories: normally open (NO) and normally closed (NC). Normally open valves allow fluid flow in the absence of electrical power, making them suitable for applications requiring constant flow until an electric signal is received to close it. On the other hand, normally closed valves remain shut unless activated by an electric signal. This makes them ideal for applications where the flow should not be present at all times. There are other variants as well, such as anti-drain valves meant to prevent backflow and maintain pressure. When selecting a valve type, it’s essential to consider the specific application requirements, as this decision directly influences the efficiency and functionality of the entire system.

HOW DOES PRESSURE AFFECT SOLENOID VALVE FUNCTIONALITY?

Pressure plays a critical role in the performance of solar solenoid valves. Each valve has a maximum pressure rating, representing the highest pressure it is designed to handle safely. Selecting a valve that can cope with both static and dynamic pressures relevant to the system ensures seamless operation without leakage or failure. If a valve is subjected to pressures beyond its limits, it may fail prematurely, necessitating costly repairs and replacements. Furthermore, fluctuations in system pressure can influence how a valve operates over time. Therefore, thoroughly assessing pressure requirements before selecting a solenoid valve is crucial for ensuring long-term performance and reliability.

WHAT MAINTENANCE IS REQUIRED FOR SOLENOID VALVES IN SOLAR SYSTEMS?

Maintenance of solenoid valves in solar systems is integral to sustaining operational efficiency and longevity. Regular inspection for wear and damage is crucial, particularly in outdoor installations where exposure to environmental factors is heightened. It is advisable to check for any residue, leaks, or corrosion around the valve body and connections. It may also be beneficial to exercise the valve periodically, ensuring it opens and closes correctly without sticking or hesitation. Depending on the type of fluid passing through the valve, cleaning may be necessary to prevent blockages. Finally, reviewing the manufacturer’s recommendations for maintenance allows operators to establish a tailored schedule specific to the system’s needs, ensuring optimal performance and durability.

5. IMPORTANT CONSIDERATIONS WHEN SELECTING A SOLAR SOLENOID VALVE

Selecting the appropriate solar solenoid valve necessitates careful deliberation of various facets to ensure optimal system operation. Understanding specific functionality requirements, assessing pressure requirements relevant to the intended application, and evaluating the durability and material selection of the valve will all significantly impact the decision-making process. Additionally, effective control mechanisms and thorough budgeting considerations will culminate in successful selection and implementation.

Investing time and resources into identifying the right valve will yield substantial returns in reliability and efficiency, minimizing potential issues down the line. A carefully chosen solar solenoid valve contributes to system longevity, operating at peak efficiency and meeting energy conservation goals. Ultimately, an informed choice encourages sustainability, aligning with broader environmental objectives. In the journey to harness solar energy efficiently, the meticulous selection of components like solenoid valves serves as a vital foundation for success.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-choose-solar-solenoid-valve/