Changing a solar diode can seem daunting, but it can be accomplished with some guidance and proper tools. 1. Identify the faulty diode, 2. Gather the necessary tools, 3. Disconnect the solar panel from the battery or load, 4. Remove the old diode, 5. Install a new diode. Each of these steps is crucial for ensuring a successful replacement that maintains the functionality of your solar system. The most critical step involves identifying the faulty diode, as it ensures other parts of the system remain unaffected.

1. INTRODUCTION TO SOLAR DIODES

Solar diodes serve a significant role in a solar energy system by ensuring the safe functioning of the overall setup. They are primarily utilized in solar panels to prevent reverse voltage, thus protecting the energy conversion components. Understanding the function of these small yet vital components is crucial for anyone involved in solar energy applications.

Awareness of the signs indicating diode failure can help solar energy users avoid larger issues in their systems. A faulty diode can result in poor energy conversion, overheating, and irreversible damage to solar panels. Therefore, it is essential to know how to address diode failures promptly. Adequate troubleshooting procedures can facilitate timely interventions.

2. TOOLS REQUIRED FOR DIAGNOSIS AND REPLACEMENT

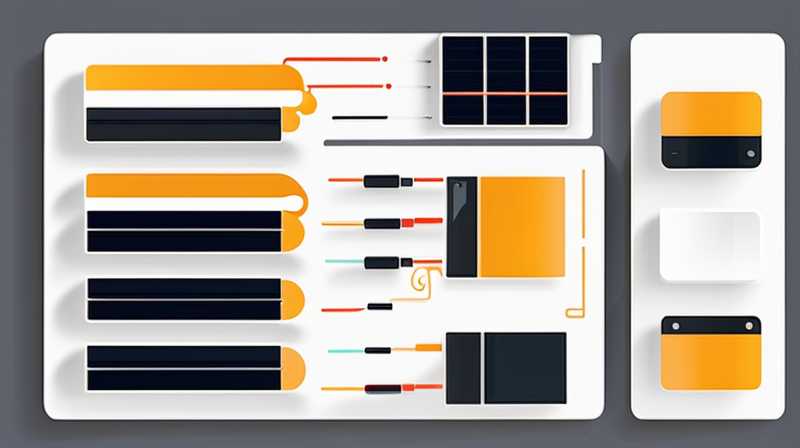

Before embarking on the diode replacement task, compiling the necessary tools is vital. A multimeter is an essential tool that enables users to measure voltage, current, and resistance within electrical components. This measurement is crucial for diagnosing whether a diode is functioning correctly or has succumbed to failure. A soldering iron, solder, and heat shrink tubing are indispensable for ensuring reliable electrical connections during the replacement process.

Using a toolkit that includes needle-nose pliers and wire cutters can make the entire operation smoother. Wire strippers will help expose fresh wire ends for making connections. Having a small flashlight or headlamp can also assist in illuminating hard-to-see areas, particularly in lower-light environments such as crawl spaces or dark rooftops. Thus, being well-prepared with the necessary tools can streamline the process considerably.

3. DIAGNOSING A FAULTY SOLAR DIODE

To determine if the diode has failed, start by performing a simple multimeter test. With the solar panel disconnected from any battery or load, set the multimeter to the diode test mode. This mode will allow for checking the forward voltage drop across the diode, indicating whether it functions correctly. A healthy diode should display a reading of around 0.5 to 0.7 volts when connected in the forward direction. An infinite reading, typically denoting a broken diode, means that a replacement is necessary.

Another method for verifying diode functionality involves the observation of physical symptoms. Burn marks, discoloration, or signs of corrosion can indicate that the diode has failed. It is essential to examine all connections within the circuit to ensure that there are no loose wires or disrupted connections, as these can exacerbate the problem. Conducting these diagnostic procedures ensures that one can pinpoint the fault accurately and that the subsequent replacement process addresses the correct issue.

4. SAFETY PRECAUTIONS DURING REPLACEMENT

Safety should always be a priority during any electrical work. Disconnecting the solar panel from batteries or electrical loads is non-negotiable before proceeding with any repairs. This disconnection minimizes the risk of electric shock and allows for a safer working environment. Wearing insulated gloves and using insulated tools significantly reduces the risk of accidents.

Another important safety measure involves working in a well-ventilated area when using soldering tools. This helps prevent inhaling harmful fumes produced during the soldering process. Additionally, if the solar panel has been exposed to sunlight prior to the replacement, it can become quite hot. Allowing sufficient time for cooling reduces the risk of burns. These precautions can go a long way in ensuring both the safety of the technician and the integrity of the solar system.

5. REMOVING THE OLD DIODE

Once the necessary tools have been gathered and safety measures implemented, the next step involves removing the defective diode. Carefully examine the solar panel’s rear to locate the diode. Many times, diodes are housed under a transparent cover or a heat sink, so gently removing any protective covers is essential. A soldering iron can be used to melt the solder securing the diode in place while maintaining precautions against overheating surrounding components.

As the existing solder begins to melt, use a pair of needle-nose pliers to carefully pull the diode away from the circuit board. All solder remnants should be cleared away to create a clean working area for the installation of the new diode. Successful removal sets the stage for inserting the new component securely.

6. INSTALLING A NEW DIODE

With the old diode removed, it is time to install the new component. Ensure that the replacement diode is of the same type and specifications as the original by checking identifiers such as voltage ratings. Align the new diode with the existing holes on the circuit board, ensuring that the anode and cathode are connected correctly—misconnecting these can result in immediate failure of the new diode.

Once positioned, secure the diode into place with solder. Applying an appropriate amount of solder is critical; too little may lead to a weak connection, while excess solder can create shorts. Allow the connection to cool down appropriately. After confirming security and proper alignment, consider applying heat shrink tubing over the solder joint to provide additional protection against environmental factors such as moisture.

7. TESTING THE NEW DIODE

After successfully soldering the new diode into position, the next step involves testing its functionality. Once again, utilize a multimeter set to diode test mode. Connect the multimeter probes to the respective ends of the new diode to measure the forward voltage drop. A reading in the expected range (approximately 0.5 to 0.7 volts) will confirm that the diode is functioning as intended.

If the reading indicates a failure, double-check that all connections are secure and that no solder bridges exist between terminals. Ensure that the multimeter is functioning correctly by testing it on a known working diode beforehand. If complications persist, consider consulting relevant documentation or seeking professional assistance. Testing ensures that all new components are functioning efficiently before reconnecting the solar panel entirely to its designated system.

8. RECONNECTING THE SOLAR PANEL

With a new diode functioning correctly, the final step involves safely reconnecting the solar panel to its load or battery. Prior to reconnecting, examine all wiring and terminals, ensuring that they are clean and free from corrosion. This inspection can help mitigate future issues and enhance overall performance.

Reconnect the solar panel to the battery or load in the designated configuration while ensuring polarity is correctly aligned. Once connections have been made, switch on the system. Monitor the panel’s output through the multimeter or other monitoring devices to ensure proper energy flow. This final verification can reassure the technician that the work has been successfully completed, leading to better energy production for the solar system.

9. MAINTENANCE AND MONITORING

Regular maintenance and monitoring of solar systems contribute significantly to their longevity and effectiveness. Check diodes and other components regularly to ensure they are operating optimally. Cleaning the surface of solar panels to remove dust and debris can also enhance efficiency.

Establishing a monitoring schedule for periodic checks can identify potential issues early before they manifest into bigger problems. Understanding when diodes and other components may need preventive replacement can ensure sustained performance and minimize downtime. Knowledge of how to attend to these components can ultimately lead to better efficiency from the solar energy installation.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE SIGNS OF A FAULTY SOLAR DIODE?

Identifying the signs of a defective solar diode is essential for maintaining an efficient solar energy system. Some common indicators include reduced power output, overheating, or visible damage such as discoloration or burn marks on or around the diode. A thorough inspection using a multimeter can provide definitive confirmation.

Another observable sign could be an irregularity in system performance; for example, if the panel’s output fluctuates without any external factors impacting it, it might indicate a diode issue. Physical inspection and routine checks can prevent the potential for more serious failures in the solar system. Conducting periodic maintenance ensures sustained operation efficiency and long-term system viability.

CAN I CHANGE A SOLAR DIODE MYSELF OR SHOULD I HIRE A PROFESSIONAL?

Changing a solar diode is a task that can be performed independently, provided one possesses the necessary tools and a basic understanding of electrical components. If you are comfortable with soldering and wiring, there is no reason to hire a professional unless the system’s design is particularly complex.

For individuals who lack experience with electrical systems, seeking professional assistance is advisable. However, taking part in learning how to manage these minor repairs can enhance understanding and reduce future costs. Deciding the best course of action depends on individual comfort levels accompanied by the system’s configuration.

HOW OFTEN SHOULD SOLAR DIODES BE REPLACED?

The lifespan of solar diodes generally aligns with that of the solar panels themselves, often lasting over 25 years. Despite this, external factors such as weather conditions, inadequate ventilation, and electrical stress may affect their longevity. Regular monitoring and maintenance can help identify diodes starting to fail and allow for preemptive replacement.

Establishing a maintenance routine—including checks for physical damage, electrical test readings, and cleaning debris from solar panels—can facilitate effective performance. Being proactive about monitoring and replacing components can enhance the long-term effectiveness of a solar energy system.

Upkeep of a solar system necessitates a meticulous approach, ensuring all components are functioning optimally to maximize energy production. Engaging with routine evaluations for the diodes will better equip users in compressing long-term repair costs and enhancing system reliability. Moreover, understanding each component’s individual role and lifespan will encourage a comprehensive approach to energy management.

The replacement process of solar diodes involves careful consideration and methodical execution. Proper preparation is essential in gathering the necessary tools and prioritizing safety. Through detailed diagnosis, removal of existing diodes, and testing the replacements, effective management of any solar system can be achieved. Ensuring connections are solid and functioning correctly promises enhanced efficacy for solar energy systems. Engaging in routine maintenance checks will reduce the risk of future failures, making it a best practice for anyone involved with solar technology. With the right knowledge, proactively changing diodes can lead to substantial long-term benefits in energy production and system reliability.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-change-solar-diode/