1. To construct a solar photovoltaic panel rack effectively, you need to consider several essential elements: 1) selecting appropriate materials, 2) determining the optimal design for your location, 3) ensuring structural integrity for various weather conditions, and 4) adhering to local regulations and codes. In detail, the selection of materials involves understanding the balance between cost, durability, and weight, with aluminum often being preferred for its lightness and resistance to corrosion, while steel offers sturdiness but adds significant weight and the potential for rust if not properly treated.

1. MATERIAL SELECTION

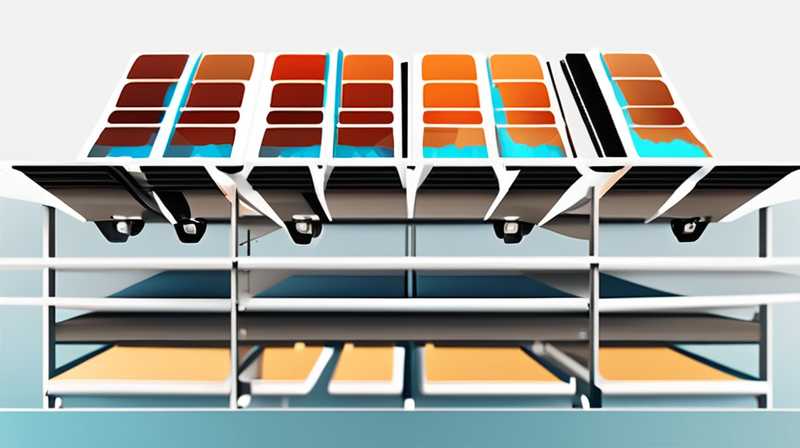

Creating a robust solar photovoltaic panel rack commences with an astute choice of materials. Aluminum, known for its lightweight properties, along with outstanding resistance to corrosion, is frequently favored. It ensures easy handling and installation, reducing the physical burden during assembly. Additionally, aluminum does not require extensive maintenance and offers longevity, which is a critical factor for outdoor installations exposed to various environmental stresses.

On the other hand, steel remains a popular option for those requiring stronger frameworks. Steel provides a level of sturdiness that can often exceed that of aluminum, particularly in supporting heavy panels in high-wind areas. However, weight presents challenges during installation, and untreated steel can succumb to rust, necessitating careful consideration in selection. The choice between aluminum and steel hinges upon the specific climate and structural demands of the installation site, thus warranting rigorous analysis before procurement.

2. DESIGN CONSIDERATIONS

After selecting the materials, the next pivotal step involves determining the design of the rack. The angle and orientation of solar panels are critical for maximizing energy capture. A well-planned incline facilitates optimal sunlight absorption throughout the year, particularly in locations that experience varying solar angles due to seasonal changes. Engineers often recommend an inclination of around 30 to 45 degrees, depending on geographical location.

Furthermore, the integration of adjustable racks can offer significant benefits. Such designs allow the angle of solar panels to be modified throughout the year, adapting to seasonal shifts in sunlight exposure, thus enhancing energy production. This flexibility can be a valuable investment for those residing in areas with pronounced seasonal variations. Moreover, ensuring that the chosen design conforms with local zoning laws and safety codes is essential to avoid future regulatory pitfalls.

3. FOUNDATION AND STRUCTURAL INTEGRITY

An aspect that significantly affects the durability and performance of a solar rack revolves around the foundation and overall structural integrity. A solid and level base is imperative, as it serves as the foundation for supporting substantial weight while withstanding various external forces like wind and rain. The choice of foundation might differ depending on whether the installation occurs on a ground mount or a roof. For ground-mounted systems, concrete footings or pier foundations can provide stability.

Additionally, bracing and cross-member support are crucial for maintaining structural integrity. Incorporating these elements minimizes sway and reinforces the rack against high winds and other environmental stresses. Engineers suggest performing site assessments and wind load calculations to determine the appropriate bracing requirements, ensuring the system’s long-term functionality and safety.

4. INSTALLATION PROCESS

Commencing the installation process demands meticulous planning. Before assembly, one must gather all necessary tools and equipment. Standard tools may include a drill, level, wrenches, and potentially a saw for any custom adjustments required. Safety equipment such as helmets and harnesses should not be neglected, particularly in elevated installations, to mitigate risks during assembly.

Once materials and tools are gathered, the actual construction can begin. Following the design plans meticulously will ensure that each component is fitted correctly and securely. An important tip is to begin with the frame construction, securing it to the foundation before mounting the solar panels. Each panel must be adequately fastened using designated hardware to mitigate vibrations and potential dislodgement during harsh weather. Test all fittings and checks for alignment along the way, which is essential for both aesthetics and functionality.

5. MAINTENANCE AND MONITORING

After the successful installation of the solar photovoltaic panel rack, the focus shifts to maintenance and monitoring. Regular inspections are necessary to ensure the integrity of the structure and the functionality of the solar panels. This involves checking for loose bolts, structural damage, or any signs of wear on the materials used.

Furthermore, monitoring energy production levels can help identify potential issues early on. Integrating monitoring systems that provide real-time data regarding energy generation assists in evaluating the performance of the solar system. In turns, these insights may guide effective maintenance strategies, improving panel efficiency over time.

COMMON INQUIRIES ABOUT SOLAR PHOTOVOLTAIC PANEL RACKS

WHAT MATERIALS ARE BEST FOR SOLAR PANEL RACKS?

The best materials for solar panel racks include aluminum and steel, each with distinct advantages. Aluminum is lightweight, resistant to corrosion, and requires minimal maintenance, making it ideal for most installations. Conversely, steel offers greater strength and sturdiness, particularly in windy regions, but it requires treatment to prevent rust. Ultimately, the choice should depend on the specific conditions of the installation site, including environmental factors and the weight capacity required.

HOW DO I DETERMINE THE OPTIMAL ANGLE FOR MY SOLAR PANELS?

To optimize solar panel performance, consider the latitude of the installation location, seasonal sun angles, and whether a fixed or adjustable rack will be utilized. As a general guideline, a tilt angle of 30 to 45 degrees typically maximizes energy absorption throughout the year. For varying seasons, adjustable racks provide flexibility to adapt to changes in sunlight angles, thereby enhancing overall efficiency and energy capture.

WHAT TYPE OF FOUNDATION IS REQUIRED FOR A SOLAR RACK?

The type of foundation needed for a solar rack largely depends on whether it is a ground-mount or roof-mount system. Ground-mounted systems often require concrete or pier footings to ensure stability and support, particularly in areas prone to high winds or heavy snow. Roof mounts, however, typically utilize anchoring systems that integrate with the roof structure, which requires careful assessment to maintain the integrity of the home or building).

In summary, constructing a reliable solar photovoltaic panel rack demands a strategic approach that encompasses critical considerations such as material selection, thoughtful design, and adherence to safety standards. Choosing the right materials can significantly influence the durability and effectiveness of the structure, with aluminum standing out for its lightweight and corrosion-resistant properties, while steel offers added strength at the potential cost of increased weight. Furthermore, establishing a robust design with the right angles and adjustments can optimize sun exposure, ultimately contributing to higher energy production. Ensuring that the foundation provides adequate support and stability under varying weather conditions is paramount, as is maintaining the system through regular inspections and monitoring. By carefully executing each of these elements and addressing common concerns around installation and maintenance, stakeholders can achieve a successful solar panel implementation, enabling both energy efficiency and cost savings over the lifespan of the installation.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-build-a-solar-photovoltaic-panel-rack/