Building a solar cell factory involves several critical steps: 1. Conduct thorough market research to identify demand and potential challenges, 2. Secure adequate funding through investors or loans to cover startup costs, 3. Choose an appropriate location that meets logistical needs and government regulations, 4. Implement a sustainable manufacturing process that includes the latest technology and materials. One key point to elaborate further is the importance of selecting the right location, as geographic advantages, access to skilled labor, and proximity to suppliers can significantly affect operational efficiency and production costs.

1. MARKET RESEARCH AND ANALYSIS

Conducting extensive market research comprises a fundamental initial step in establishing a solar cell factory. In-depth understanding of the market dynamics is quintessential for determining the feasibility of the project. Solar energy has gained immense traction due to its eco-friendly nature and governmental push for renewable energy sources. Evaluating both local and global market trends enables an entrepreneur to forecast potential demand accurately.

Effective analysis should encompass an examination of competitors, identifying their strengths and weaknesses. By scrutinizing competitors, one can determine gaps in the market that the new venture might exploit. This prompts the development of a unique selling proposition that differentiates the solar cell factory from existing market players, allowing one to capture and maximize potential market share.

2. FUNDING REQUIREMENTS

Securing adequate funding stands as a critical aspect in the lifecycle of any business venture, particularly in capital-intensive industries such as solar energy. A comprehensive financial plan should outline all necessary costs, from securing equipment to hiring skilled personnel, ensuring that the operation starts with solid financial backing.

Funding sources can vary, encompassing personal investments, loans from financial institutions, or attracting venture capital. Presenting a robust business plan that highlights market potential, operational strategies, and projected profitability can significantly enhance the likelihood of attracting financial support. Moreover, awareness of various funding mechanisms, such as grants or government incentives aimed at renewable energy projects, allows one to optimize funding strategies effectively.

3. LOCATION SELECTION

Choosing an appropriate site for the solar cell factory is crucial for operational efficiency and overall success. The location impacts numerous factors, including proximity to supply chains, access to skilled labor, and logistical convenience for transporting finished products. A careful evaluation of these factors not only influences the production cost but also organizational sustainability.

In addition to logistical considerations, regional policies and regulations play a vital role in location selection. Some regions offer incentives for renewable energy initiatives, such as tax breaks or grants that can significantly reduce operational costs. Engaging with local governments ensures compliance with regulations, fostering a development environment that is conducive to business growth.

4. TECHNOLOGY SELECTION

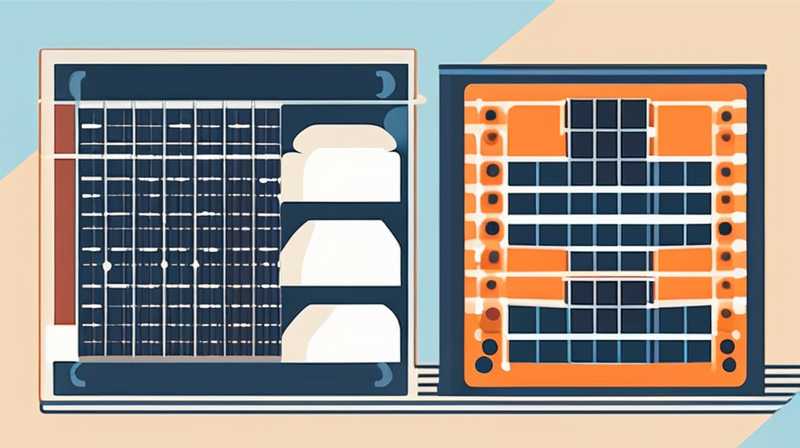

In the production of solar cells, selecting the right technology is paramount for ensuring quality and efficiency. Numerous manufacturing processes, such as thin-film technology and crystalline silicon technology, come with varying efficiency rates, costs, and environmental footprints. Careful evaluation of these technologies allows entrepreneurs to make informed decisions aligned with their production capabilities and sustainability goals.

Investment in cutting-edge technology can lead to substantial returns through improved production rates and superior product quality. Research into emerging technologies may also reveal innovative methods that can reduce costs while enhancing product efficiency. Engaging with industry experts to understand new advancements keeps the factory competitive in a rapidly evolving market.

5. SUSTAINABLE MANUFACTURING PRACTICES

Integrating sustainable manufacturing practices plays a significant role in the production of solar cells, contributing to both environmental sustainability and social responsibility. Establishing processes that minimize waste and utilize renewable energy sources not only enhances the factory’s image but also improves operational efficiency, thereby reducing costs over time.

Implementation of recycling processes for materials and eco-friendly waste disposal measures creates a responsible manufacturing environment. Such practices contribute to reduced carbon footprints, fulfilling corporate social responsibilities while meeting the increasing consumer demand for sustainability in the product lifecycle. Consumers, clients, and investors are increasingly valuing sustainability, making it an important factor for long-term business success.

6. QUALITY CONTROL MEASURES

Establishing rigorous quality control measures is integral to ensuring that manufactured solar cells meet industry standards and customer expectations. This could include implementing automated testing processes, stringent inspections, and employing trained quality assurance personnel. Creating a culture of quality within the organization encourages employees at all levels to prioritize product integrity.

The integration of quality management systems (QMS) can help in monitoring processes continuously. By leveraging data analysis, issues can be identified and addressed proactively, reducing the risk of defects that lead to higher costs and damaged reputations. A commitment to quality ultimately establishes a brand’s reliability, translating into repeat business and customer referrals in an increasingly competitive market.

7. SUPPLY CHAIN MANAGEMENT

Efficient supply chain management significantly influences the production timeline and overall product quality. Building robust relationships with suppliers for materials and components is essential for maintaining consistency and reliability in production. It is imperative to work with suppliers who adhere to ethical practices and offer quality resources suitable for solar cell manufacturing.

Additionally, diversifying suppliers mitigates risks associated with supply chain disruptions, ensuring that production can continue uninterrupted even when faced with unforeseen events. Comprehensive risk assessment strategies can enhance supply chain resilience, improving overall business stability while optimizing operational efficiency.

8. MARKETING AND SALES STRATEGY

A well-considered marketing and sales strategy can propel a solar cell factory to commercial success. Understanding the target market segments and effectively addressing their needs allows for the generation of interest and engagement. Crafting a compelling brand message highlighting the advantages of solar energy assists potential clients in making informed decisions.

Marketing channels can range from digital marketing to traditional advertising, ensuring wide-reaching promotion. Engaging with social media platforms, industry forums, and trade shows cultivates interest and positions the factory as a leader in solar innovation. A balanced strategy that combines awareness and relationship building enhances client acquisition and retention.

Frequently Asked Questions

WHAT IS THE INITIAL INVESTMENT REQUIRED TO BUILD A SOLAR CELL FACTORY?

The initial capital required to establish a solar cell factory can vary significantly based on several critical factors. On average, a small to medium-sized facility may necessitate an investment ranging from one million to several million dollars. This variance depends on the scale of production, choice of technology, and the selected location.

Key components of startup costs include equipment procurement, facility construction or leasing, raw material sourcing, and hiring of skilled labor. Outlay for regulatory compliance and marketing must also be factored into the financial plan. Engaging financial experts in creating a comprehensive budget ensures that all anticipated expenses are accounted for, thereby facilitating a smoother setup and operational phase.

HOW LONG DOES IT TAKE TO COMPLETE THE CONSTRUCTION OF A SOLAR CELL FACTORY?

The timeframe for constructing a solar cell factory is influenced by various factors, including size, design complexity, and local regulatory requirements. On average, one can anticipate a timeline of anywhere between six months to two years from inception to operational status. Initial phases such as land acquisition, site preparation, and permitting can consume considerable time.

Following these phases, the actual construction and installation of equipment commence. Adherence to a clear project schedule, while ensuring that all regulations and standards are met, is crucial in minimizing delays. Collaborating closely with contractors and industry experts can streamline this process, eventually leading to timely project completion.

WHAT ARE THE ENVIRONMENTAL IMPACTS OF SOLAR CELL PRODUCTION?

The environmental impacts of solar cell production encompass diverse aspects, ranging from raw material extraction to manufacturing processes. While solar cells contribute to renewable energy, the production phase can pose certain environmental challenges. Utilization of harmful substances and energy-intensive processes can lead to negative consequences if not managed responsibly.

However, advancements in technology and materials aim to mitigate these effects. Employing sustainable materials, improving energy efficiency, and implementing recycling practices can significantly alleviate environmental burdens. It’s crucial for producers to adopt comprehensive environmental management strategies that minimize waste and optimize resource usage, thereby enhancing sustainability in solar cell manufacturing.

Building a solar cell factory is a multifaceted endeavor that requires careful planning, strategic foresight, and a commitment to sustainable practices. Recognizing the vital importance of market research lays the foundation for informed decision-making throughout the process. Secure funding is essential to overcome the challenges associated with initial costs, enabling the procurement of advanced technologies that enhance production efficiency. Choosing the right location ensures access to essential resources, skilled labor, and advantages of local regulations that promote renewable energy initiatives. Implementing ethical sourcing, robust supply chain management, and sustainable manufacturing not only reduce operational costs but also positions the factory favorably in a market that increasingly values environmental responsibility. Quality control ensures products meet necessary standards, fostering trust amongst consumers and clients. As the demand for solar energy solutions continues to soar, establishing a factory grounded in these principles will pave the way for success in the ever-evolving renewable energy landscape.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-build-a-solar-cell-factory-2/