To effectively break a solar iron pipe, one must consider several critical aspects, including 1. Knowledge of Materials, 2. Safety Precautions, 3. Appropriate Tools, 4. Techniques for Breaking, and 5. Proper Disposal Methods. Understanding the composition of solar iron pipes is essential, as they are often made from durable materials that can be challenging to fracture. Various recommended methods exist for breaking these pipes, including physical and chemical approaches. Safety should be the foremost concern, employing protective gear and ensuring the surrounding area is free from hazards. The choice of tools significantly impacts the success of the task; using improper tools may lead to ineffective results or potential injuries. Finally, the disposal of the broken pieces must adhere to local regulations to avoid environmental harm.

1. KNOWLEDGE OF MATERIALS

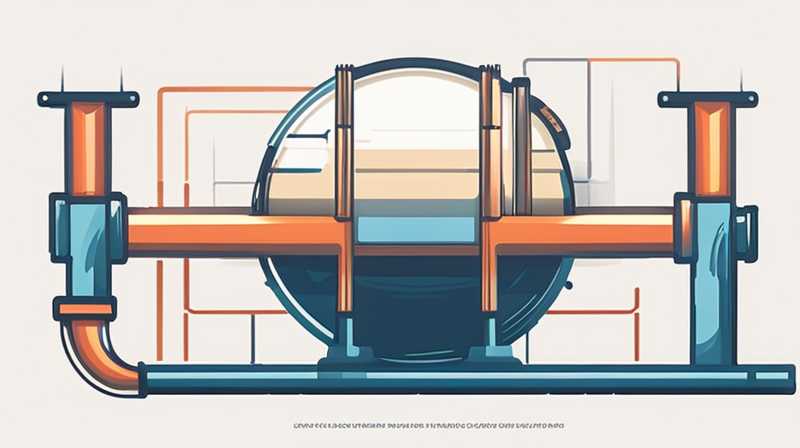

Understanding the composition of solar iron pipes is fundamental to successfully breaking them. Solar iron pipes are typically designed to endure high temperatures and pressures, and as such, they are manufactured from robust materials that might include galvanized steel or stainless steel. This robustness is beneficial for their intended purpose in solar energy systems, where they must transport thermal energy efficiently.

The structure of these pipes presents challenges when attempting to break them. For instance, galvanized pipes have a protective zinc coating that can make them more durable than other metals; this characteristic should be taken into account. Furthermore, it is crucial to be aware of any coatings or treatments that may enhance the pipe’s resistance to wear and tear. The mere recognition that some solar iron pipes may be insulated further complicates the matter, as one must take their insulation into account when choosing breaking methods.

2. SAFETY PRECAUTIONS

Prioritizing safety is absolutely essential when attempting to break a solar iron pipe. The nature of the materials involved can pose various risks, including sharp edges or the potential for mechanical failure. Wearing appropriate personal protective equipment (PPE) is obligatory. Essential gear includes gloves, safety glasses, and steel-toed boots to provide maximal protection during the operation.

Additional precautions should be considered, such as ensuring that the area is well-ventilated, especially if chemical methods are employed. It is also wise to have first aid provisions readily available, as accidents can occur unexpectedly. Prior to initiating the task, clear the workspace of clutter and ensure that all electrical and water sources are turned off to eliminate any hazards that may lead to accidents.

3. APPROPRIATE TOOLS

Using the right tools is critical for safely and effectively breaking a solar iron pipe. Manual tools can include hammers, chisels, and pipe cutters, but it’s essential to select those that are suitable for the pipe’s material and size. Heavy-duty pipe cutters, for instance, may offer a clean break with minimal risk of creating hazardous shards.

For more extensive or tougher pipes, powered tools such as reciprocating saws or angle grinders may be employed, but one must use these with caution. The selection of tools must align with the methods chosen and the nature of the material to avoid complications. It is also advisable to familiarize oneself with the operation of these tools before attempting to use them on the solar iron pipe to ensure that the procedure is handled efficiently.

4. TECHNIQUES FOR BREAKING

Multiple techniques are available for breaking a solar iron pipe, and each approach has its own merits. Physical methods, such as manual breaking with a hammer and chisel, require considerable strength and precision. This method may be appropriate for smaller pipes but can be impractical for larger, more robust versions.

Alternatively, chemical methods present an effective solution for certain operators. Utilizing specific solvents can weaken the bonds within the pipe material, making it more manageable to break. Understanding the chemical’s properties and ensuring that it is appropriate for the material of the pipe is critical. Moreover, ensuring the removal of any hazardous chemical residues is essential for environmental safety.

5. PROPER DISPOSAL METHODS

Proper disposal of broken solar iron pipe remnants is of paramount importance. Local regulations typically govern the disposal of metal materials, which necessitates a clear understanding of the required protocols. It’s crucial to familiarize oneself with metal recycling processes, as many components can be repurposed, minimizing waste and promoting environmental sustainability.

One option for disposal is to contact local waste management services to inquire about designated drop-off locations for recyclables. Many regions have specific guidelines for handling scrap metal, which ensures that these materials do not end up in landfills unprocessed. By adhering to these guidelines, one not only complies with legal obligations but also contributes to broader initiatives aimed at recycling and resource conservation.

FAQS

WHAT TYPES OF TOOLS ARE IDEAL FOR BREAKING SOLAR IRON PIPES?

When selecting tools for breaking solar iron pipes, it is critical to consider the specific characteristics of the pipe material. Depending on the diameter and thickness, pipe cutters and reciprocating saws are frequently employed for more comprehensive cutting needs. Manual tools, such as hammers and chisels, can also suffice for smaller jobs but require precision and safety precautions. It is necessary to understand the strength and durability of the materials involved since some may resist traditional methods of breaking. Regardless of the tools chosen, prioritizing safety by wearing PPE is fundamental in avoiding potential injuries during the process.

IS IT SAFE TO USE CHEMICALS TO BREAK SOLAR IRON PIPES?

Utilizing chemicals to break solar iron pipes can be effective; nonetheless, this approach requires careful consideration. Chemicals designed to weaken metal bonds can accelerate the breaking process, but an understanding of the particular materials and the chemical’s properties is essential. Safety precautions must be followed strictly, including wearing protective gloves and eyewear and ensuring adequate ventilation. Moreover, any chemical residues necessitate proper disposal as per local regulations, ensuring environmental protection while minimizing risks associated with the use of hazardous substances. It is wise to weigh the benefits against the potential dangers when deciding to employ chemical methods for breaking pipes.

HOW CAN I DISPOSE OF THE BROKEN PIECES OF SOLAR IRON PIPE PROPERLY?

Proper disposal of broken solar iron pipe fragments is essential for adhering to environmental regulations. Many municipalities offer recycling services specifically for metallic materials, and it’s advisable to contact local waste management to find drop-off locations. Some areas host specialized recycling centers that accept scrap metal, ensuring the material is processed correctly. Moreover, when disposing of these pieces, it is prudent to segregate them from regular waste to promote recycling. Compliance with local disposal guidelines not only fosters environmental affiliation but also minimizes ecological impacts associated with improper waste management practices.

In essence, breaking a solar iron pipe involves a series of meticulous steps and considerations. One must prioritize a comprehensive understanding of the materials to fully appreciate their characteristics and resistance levels, as the pipes’ durable composition mandates specific breaking methods. Safety cannot be overstated; proper gear and positioning are integral to mitigating risks. The correct selection of tools is also vital, as they enable efficiency and reduce the likelihood of accidents. Examining the various methods for breaking pipes, including physical and chemical strategies, reveals that operators should be well-informed about their respective benefits and drawbacks. Lastly, adherence to disposal guidelines is not merely a regulatory requirement; it also reflects individual responsibility toward environmental health. By taking a thoughtful approach to each of these elements, one can navigate the complexities of breaking solar iron pipes effectively and safely, emphasizing the importance of preparation, execution, and responsible aftercare throughout the entire process.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-break-the-solar-iron-pipe/