To effectively package solar panels, consider several critical factors, including 1. Selecting appropriate materials for protection, 2. Implementing proper cushioning techniques, 3. Ensuring secure handling during transportation, 4. Adhering to relevant regulations and standards. Notably, the correct choice of materials greatly affects the safety and integrity of solar panels during transit. For instance, using strong, durable materials that can withstand external pressures and impacts is vital. Opting for packaging that is both lightweight and robust ensures the efficiency of shipping while minimizing the carbon footprint. Furthermore, effective cushioning will absorb shocks and mitigate the chances of damage, particularly for delicate components. Ultimately, understanding and complying with guidelines specific to solar panel transport can help prevent legal issues and ensure product safety.

1. UNDERSTANDING SOLAR PANEL STRUCTURE

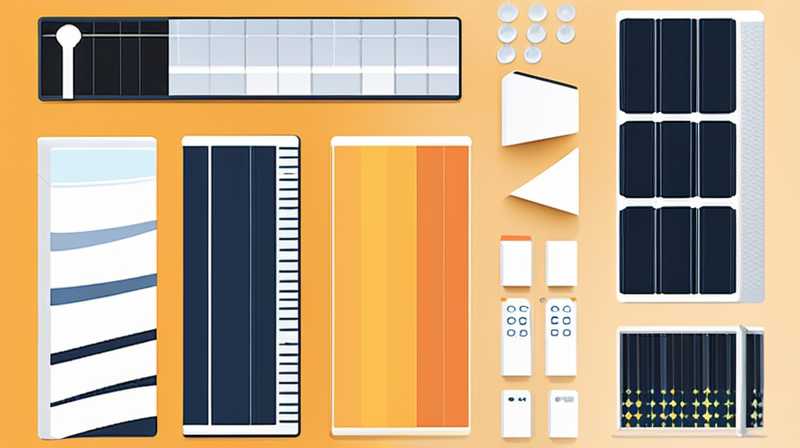

The fundamental design of solar panels significantly influences packaging strategies. Solar panels comprise sensitive components such as photovoltaic cells, glass layers, and protective backing materials. Each of these elements requires careful consideration when determining the most effective packaging solutions. Due to the fragile nature of photovoltaic cells, the primary concern while packaging is to avoid any impact or pressure that might cause breakage. Thus, one must focus on a packaging design that provides maximum protection by utilizing quality cushioning materials and robust outer shells.

Moreover, the weights and dimensions of these panels can vary quite significantly. Understanding the specific dimensions, weight limits, and structural features of the solar panels is imperative in developing a tailored packaging solution. Different panel designs may require varied stacking methodologies and configurations. While one type may be small and compact, another could be significantly larger, necessitating a flexible approach during the design and implementation phases of the packaging process to ensure their safety and usability during shipping.

2. MATERIAL SELECTION FOR PACKAGING

Choosing appropriate materials is a cornerstone of effective solar panel packaging. High-quality cardboard boxes, custom-engineered foam, and shock-absorbent materials ensure optimal protection. Corrugated cardboard boxes are commonly used due to their lightweight yet sturdy nature. They are readily available and can be constructed to varying sizes specifically suited to the dimensions of solar panels. When combined with necessary cushioning materials, such as foam inserts or inflatable air pillows, firm support is achieved, minimizing the risk of damage.

Evaluating the environmental aspect when selecting materials is also paramount. Biodegradable and recyclable materials provide sustainability options that align with the renewable energy ethos of solar panels. This not only enhances the ecological footprint of the packaging process but also appeals to eco-conscious customers. Striking a balance between sustainability and protection is essential in modern packaging strategies, as they will be vital in maintaining the integrity of both the product and the environment.

3. EFFECTIVE CUSHIONING TECHNIQUES

Cushioning is a critical component that protects solar panels from shocks and vibrations during transportation. Effective cushioning techniques include the use of foam padding, biodegradable packing peanuts, and custom-fit inserts. The goal is to create a buffer that absorbs impact energy, thus shielding the solar panels from potential damage. A common method involves layering foam padding along the inside of the packaging containers, which serves as a protective barrier between the panels and any external forces that might be encountered during shipping.

Custom-fit inserts made from rigid foam can also add significant protection to the solar panels. These inserts hold the panels securely in place, preventing any movement within the packaging during transit. The combination of custom inserts and additional padding provides a dual layer of protection. Additionally, inflation packing material can be utilized, which conforms tightly to the shape of the panels, providing utmost stability while minimizing weight. Ensuring that the solar panels are immobile within the packaging prevents unnecessary friction and potential misalignment that could lead to panel damage.

4. SECURE HANDLING PRACTICES

Ensuring safe handling practices during transportation is an integral element in safeguarding solar panels. Employees involved in the packaging and shipping processes should receive proper training on handling fragile materials. This training should encompass techniques for lifting, loading, and transporting panels to mitigate the risk of accidental damage. Training emphasizes proper lifting techniques, usage of handling equipment, and what to do in case of unexpected situations.

Moreover, the use of clear signage and labeling on packages is essential to communicate fragility. Labels indicating “Handle with Care” or similar warnings help alert handlers to exercise caution. When managed correctly, these practices establish a foundation for safe transportation procedures. Encouraging feedback from transportation personnel about potential issues can lead to improvements in handling processes, further enhancing the overall safety of solar panel transit.

5. REGULATIONS AND STANDARDS

Navigating the complex world of regulations and standards is crucial when packaging and transporting solar panels. Performing extensive research on relevant industry guidelines can avert legal complications and ensure compliance. Different countries have specific regulations governing the transport of fragile goods, often requiring adherence to safety standards during shipping. Knowing these regulations is vital for manufacturers and distributors, as failure to follow outlined guidelines can lead to delays, fines, or damages.

Additionally, engaging with certification organizations and adhering to industry standards can enhance product credibility in the market. Certifications provide assurance to consumers regarding the quality and reliability of the packaging solutions. Companies that actively pursue compliance display their commitment to safety and quality, which can enhance their brand image and foster trust with consumers, ultimately leading to increased sales and stronger market positioning.

6. COST-EFFECTIVE PACKAGING SOLUTIONS

Developing cost-effective packaging solutions is essential for maintaining a profitable operation. Evaluating various packaging options and comparing costs without compromising quality ensures economic efficiency. While opting for high-quality materials may implicate higher upfront costs, implementing durable packaging can reduce the overall risk of damage, resulting in fewer returns and savings in the long run.

Additionally, businesses should assess shipping logistics when considering packaging costs. Optimizing packaging dimensions can also lead to significant savings in shipping fees, as smaller packages often incur lower costs and reduce carbon footprints. Implementing a strategy focusing on both quality and cost-effectiveness allows businesses to enhance their packaging methodology while maintaining profitability.

7. DETERMINING THE APPROPRIATE SHIPPING METHOD

Selecting the right shipping method plays a crucial role in ensuring the safe delivery of solar panels to their end destination. Factors like distance, climate, and mode of transportation will impact the final choice of shipping method. For instance, ground shipping may be adequate for shorter distances, while air freight may be necessary for urgent deliveries. However, air freight can be much more expensive, so it is essential to weigh urgency against cost.

Environmental considerations should also be evaluated during the shipping process. Opting for carbon-neutral transportation options or those that utilize sustainable practices aligns with the overall sustainability goals of solar energy. Choosing a reliable shipping partner experienced in handling fragile goods is also paramount; they should provide tracking information and maintain communication throughout the transit process, ensuring peace of mind for all parties involved.

FAQs

WHAT MATERIALS ARE RECOMMENDED FOR PACKAGING SOLAR PANELS?

When packaging solar panels, selecting robust materials is vital. Corrugated cardboard boxes, high-density foam, and protective cushioning serve as suitable packaging options. Corrugated cardboard offers durability while being lightweight, reducing shipping costs. High-density foam protects against impacts, while cushioning materials fill voids and prevent movement during transit. Furthermore, opting for environmentally friendly materials such as biodegradable packing peanuts aligns with sustainable practices, enhancing the overall appeal to eco-conscious consumers.

HOW CAN HANDLING PROCEDURES BE IMPROVED?

Improving handling procedures involves training and implementing best practices for employees. Training focuses on safe lifting techniques, proper use of equipment, and the importance of handling fragile materials. Regular workshops or safety briefings can reinforce this training, keeping safety protocols fresh in employees’ minds. Moreover, imposing strict guidelines regarding the transportation of delicate products enhances accountability. Establishing a feedback loop for employees can help identify pain points and lead to continuous improvement in handling processes, minimizing risks and enhancing safety.

WHAT REGULATIONS SHOULD BE CONSIDERED WHEN PACKAGING SOLAR PANELS?

Understanding regulations is pivotal for compliant solar panel packaging. Countries often have specific guidelines governing the transport of fragile goods, including solar panels. Researching local and international regulations can prevent legal issues. Institutions like the International Organization for Standardization (ISO) provide relevant guidelines that manufacturers should follow. Additionally, ensuring adherence to certifications related to safety standards can build trust with consumers and improve market positioning, reinforcing the quality and reliability of the packaging solutions used.

Embarking on the journey to package solar panels effectively is no small feat. Various facets play a significant role in guaranteeing product safety during transportation. From understanding the structural intricacies of the panels to selecting premium materials, attention to detail is of utmost importance. Cushioning techniques and secure handling practices not only safeguard the product but also reflect the ethos of sustainability embedded in solar technology. By adhering to industry regulations and striving for cost-effective solutions, companies can maintain profitability while delivering reliable products.

In an era increasingly leaning towards sustainable energy, the packaging of solar panels cannot be overlooked. As solar energy continues to gain traction worldwide, ensuring the efficient transport of solar panels becomes increasingly relevant. By investing in high-quality packaging solutions that protect these fragile products during transit, businesses can ensure successful deliveries and uphold their brand reputation. Ultimately, the overall commitment to effective packaging translates into enhanced consumer trust, bolstered sales, and contributes to the planet’s sustainability objectives—benefits that resonate far beyond mere packaging material.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-best-package-solar-panels/