To effectively bend solar pipes, one must follow a series of precise steps and utilize the appropriate tools to ensure both functionality and integrity of the pipes. There are several methods to achieve this, including 1. Heat application, 2. Bend radius determination, 3. Use of bending equipment, and 4. Checking for defects. Among these, the most critical process involves using heat to soften the material, allowing for controlled bending without compromising the structural integrity.

UNDERSTANDING SOLAR PIPES

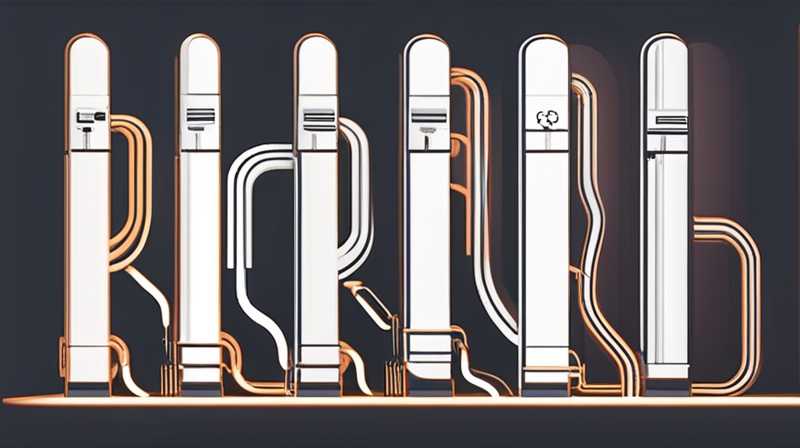

Solar energy systems primarily employ pipes for transporting heat transfer fluids. These fluids facilitate the transfer of solar heat collected by panels to applications for heating and power generation. Solar pipes, often constructed from materials like copper or PEX, present unique challenges when bending because the integrity and flow efficiency must remain intact.

The bending process serves several purposes, including minimizing the distance between solar collectors and storage tanks, optimizing system efficiency, and integrating seamlessly into existing structures. When improperly bent, pipes may kink or develop weak points, leading to potential failures that compromise the effectiveness of the system.

BENDING TECHNIQUES UTILIZED IN SOLAR PIPE INSTALLATION

Implementing the right bending technique is key to achieving optimal results in solar pipe installation. Various methods exist, each with its advantages and limitations.

HEAT BENDING

Heat bending involves using an external heat source to warm the pipe material prior to bending. This approach works exceedingly well for plastic materials, while metallic pipes necessitate greater caution. When heating a solar pipe, it is crucial to maintain an appropriate heat level without overheating, which could cause damage.

To perform heat bending, one must prepare the pipe by measuring the desired bend and marking guidance lines. Heating is typically executed with heat guns or specialized bending ovens, ensuring that the temperature reaches a point just above the material’s melting or softening point. Once adequately heated, the bending process must be conducted swiftly yet carefully to avoid cooling before achieving the desired angle.

MECHANICAL BENDING

Mechanical bending employs specialized tools, such as pipe benders or mandrel benders. This approach is particularly beneficial for metal pipes, as it ensures that the pipe maintains its shape and structural integrity even under extreme bends.

Utilizing these bending tools requires not just skill but also an understanding of the specific properties of the materials in use. The bend radius, which is the distance from the centerline of the pipe to the outer surface of the bend, must be carefully calculated for effective use of mechanical benders. Improper calculations can lead to significant issues, including kinks and reduced flow capacity.

OTHER CONSIDERATIONS FOR PIPE BENDING

In addition to selecting the proper bending method, various considerations must be taken into account throughout the process. The material type and thickness directly influence the chosen technique.

MATERIAL SELECTION

The material used in solar piping affects its bendability. Copper pipes, for instance, can often be manipulated more easily than rigid materials such as PVC or other plastics. Understanding the properties of the material is crucial, including the tensile strength and ductility which dictate how much force can be applied without causing structural failure.

Additionally, when selecting pipe material for bending, consider its thermal expansion and contraction properties. As temperatures fluctuate, pipes will change dimensionally. If bends are not designed with this in mind, the system could experience significant stress and potential leakage at the joints.

BEND RADIUS AND ANGLE

The bend radius is a pivotal factor in the bending process, since it can significantly influence the fluid dynamics within the pipe and therefore the overall efficiency of the solar system. A bend that is too tight will inherently increase the amount of turbulence in the flow, leading to a decrease in energy efficiency.

When establishing the necessary bend angle, it is also essential to maintain consistent flow. Angles that are excessively sharp can create obstructions and pressure drops, which hinder the performance of the piping system. Generally, a bend radius of at least three times the diameter of the pipe is recommended as a rule of thumb.

TOOLS REQUIRED FOR PIPE BENDING

A range of tools is available for bending solar pipes, varying from manual handheld tools to electric machines designed for industrial applications. Selecting the right tool can improve not only the effectiveness but also the safety of the bending process.

HANDHELD PIPE BENDERS

For smaller projects or DIY installations, handheld pipe benders provide a practical solution. These manual tools allow for a good degree of control, making them ideal for bending small sections of piping without excessive force.

One must remember to use a bender designed for the specific pipe size to avoid damage or misalignment during the bending process. This equipment often incorporates guides that make it easier to achieve consistent angles and prevent the pipe from collapsing during the operation.

POWERED PIPE BENDERS

For larger installations or more extensive projects, powered or hydraulic benders are highly recommended. These machines apply consistent pressure across the length of the pipe, ensuring even bends while significantly reducing physical labor.

Moreover, these tools come equipped with various settings that can accommodate a range of pipe sizes and materials, making them versatile for different solar projects. While the initial investment may be higher, the efficiency and results achieved often justify the expense.

UNSUNG BENEFITS OF PIPE BENDING IN SOLAR INSTALLATION

Beyond its functional aspects, bending enables several additional advantages that impact the overall system’s viability. Optimizing space and enhancing aesthetic appeal are often overlooked benefits.

SPACE OPTIMIZATION

In densely populated areas or locations constrained by space, the ability to bend pipes allows for more compact solar installations. By strategically routing pipes around obstacles, contractors can minimize the necessary installation footprint while ensuring an efficient design.

This spatial efficiency not only aids in deployment but can also reduce costs associated with additional materials and man-hours during installation.

AESTHETIC INTEGRATION

Aesthetics play a critical role in the acceptance of solar installations in residential and commercial settings. Bending pipes allows for seamless integration into existing structures, significantly reducing the visual impact. Smooth, thoughtful designs enhance property appearance while avoiding unsightly configurations that might lead to community pushback.

MAINTENANCE TIPS FOR BENT SOLAR PIPES

Regular inspection and maintenance are paramount for ensuring the longevity and efficiency of bent solar pipes. Minor issues can escalate into major concerns if not addressed promptly.

REGULAR INSPECTIONS

Conduct regular visual checks for any signs of wear, leaks, or misalignment in bent sections. By catching problems early, one can prolong the lifespan of the pipe and maintain system efficacy.

Long-term monitoring also involves understanding environmental influences on the piping—temperature changes, physical damage, or chemical exposure can all play a role. Utilizing smart monitoring technology allows for real-time assessments of operational efficiency.

PROPER SUPPORT STRUCTURES

To ensure the integrity of bent solar pipes, the use of appropriate support structures is crucial. Properly securing pipes along their lengths with system brackets or hangers keeps them stable, reducing strain on bends and joints. These supports should allow for some movement while preventing undue stress that might lead to cracks or breaks.

ENSURING EFFICIENCY IN BENDING PROCESS

Achieving successful bends in solar piping requires a clear methodology focused not only on the technical aspects but also on creating an organized workspace and maintaining a systematic approach.

PLANNING

Planning prior to executing any bends can prevent headaches down the line. Map out the system layout carefully, calculating all bends and confirming measurements before commencing work.

By having an organized workstation with all necessary tools at hand, the bending process will be smoother and more efficient. Preemptive planning minimizes the likelihood of mistakes that could require rework or lead to wasted materials.

SAFETY CONSIDERATIONS

Given the physical demands of bending pipes, proper safety measures are essential. Utilizing personal protective equipment (PPE), such as gloves and eye protection, can safeguard against potential injuries from heat and sharp edges.

Further, ensuring that tools are routinely maintained and in good working order minimizes accidents and slips during the bending process. Recognizing the correct techniques and methodologies protects not just the individual performing the work but also the integrity of the system being installed.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE RECOMMENDED BEND RADIUS FOR SOLAR PIPES?

When bending solar pipes, the recommended bend radius varies depending on the material used. Generally, a radius of at least three times the diameter of the pipe is advisable. For example, if the outer diameter of the pipe is 1 inch, the bend radius should be no less than 3 inches. Maintaining an appropriate radius is crucial for preventing turbulence and potential blockages that could arise from sharp bends.

Additionally, using improper bend radii can lead to stress concentrations in the material, increasing the risk of leaks or pipe failure. Therefore, precise measures and adherence to these guidelines are critical to ensuring optimal functionality and longevity of the pipes.

CAN I BEND SOLAR PIPES MYSELF?

Yes, bending solar pipes can be accomplished using various methods, and DIY projects are quite common. However, it is important to have the right tools and knowledge of the materials involved to avoid damaging the pipes. Handheld pipe benders, heat guns, and appropriate safety gear are essential for success in this endeavor.

While looking to save costs, proper technique should not be overlooked. If in doubt, hiring a professional may yield better outcomes. The expertise of skilled technicians ensures that the bends are executed safely and correctly, promoting efficient performance in the solar system.

HOW CAN I AVOID KINKS OR DAMAGE WHEN BENDING PIPES?

To avoid kinking or damaging pipes during the bending process, employing the right technique and tools is paramount. Heating pipes evenly prior to bending can significantly reduce the risk of damage. For plastic materials, controlling the temperature ensures that the material does not become too soft or melt.

Additionally, using equipment designed specifically for the pipe’s diameter and material will ensure a smoother bend. Gradually applying pressure allows for better control, which further decreases the likelihood of creating kinks or sharp angles that can disrupt the flow of fluids.

FINAL THOUGHTS

Bending solar pipes is fundamental in achieving efficient and optimized solar energy systems. Proper methods tailored to the material of the pipes, combined with a keen understanding of bend radius, play a critical role in the successful implementation of these installations. The selected techniques must align with the specific requirements of the project, considering factors such as strain, thermal properties, and environmental influences. Furthermore, regular maintenance and inspections assure longevity and functionality of the pipes. Hence, investing time and resources into acquiring the correct tools and techniques is not just advisable, but essential for anyone involved in solar pipe installations. Such diligence ensures that the entire solar energy system operates at peak efficiency, translating into reliable energy production and transformative impacts on consumer sustainability.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-bend-solar-pipes/