To assemble a Yuanneng solar bracket successfully, follow these steps: 1. Gather all necessary tools and components, ensuring you have screws, brackets, and tools like a wrench or screwdriver. 2. Lay out the solar panel on a flat surface for ease during assembly. 3. Start attaching the base brackets to the frame of the solar panel using the appropriate screws. 4. Securely fasten the brackets to avoid any movement or instability during installation on the roof or ground. 5. Finally, adjust the angle of the brackets if necessary for optimal sun exposure. This methodical approach facilitates a well-structured assembly process, guaranteeing the stability and effectiveness of solar energy capture.

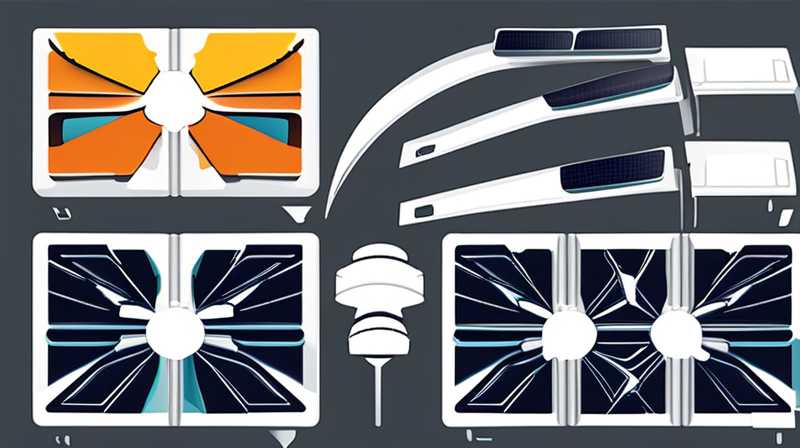

1. UNDERSTANDING THE COMPONENTS OF A YUANNENG SOLAR BRACKET

Assembling a Yuanneng solar bracket necessitates a comprehensive understanding of its components. Primarily, this assembly involves various parts: the brackets, mounting screws, screws for the solar panel, and the base. Each individual component plays a critical role in the effectiveness and stability of the overall system. Thorough examination and handling of these pieces will contribute to efficient assembly.

The structural integrity of the solar brackets largely relies on the material and design caliber. Yuanneng products are typically built with durability in mind, featuring corrosion-resistant materials. This is particularly important because solar panels are exposed to diverse climatic conditions. A robust bracket ensures that the panels remain secure and operational over long periods. Carefully reviewing the manufacturer’s specifications will provide better insights into each component’s purpose and layout.

2. PREPARING FOR ASSEMBLY

Before diving into the assembly, meticulous preparation is essential. A conducive workspace that is organized and free from distractions will facilitate a smoother and more efficient process. Gather all required tools, including socket wrenches, screwdrivers, and measuring tapes. Having these items within reach minimizes interruptions and enhances operational efficiency.

Equally important is the identification of each component of the bracket system. Familiarizing yourself with the mounting components, bolt types, and alignment tools will save time during assembly. It is advisable to read through the instruction manual provided by Yuanneng to understand the specific configurations needed for the solar system being assembled. Furthermore, ensuring that each tool is in good working condition will eliminate potential hindrances during the assembly phase.

3. ASSEMBLING THE BASE BRACKETS

The stability and efficiency of solar panels begin with the correct assembly of base brackets. To initiate this process, the brackets should be positioned according to the solar panel’s dimensions. The base brackets will serve as the foundation; their proper installation directly influences the solar panel’s angle and sun exposure. Manufacturers typically provide specifications depicting how many brackets are necessary, depending on the number of solar panels.

Aligning the brackets correctly is critical. Use the specified measuring tape to ensure even spacing and optimal alignment. Once positioned, insert screws through the pre-drilled holes on the brackets. Employ a wrench to tighten the screws firmly yet cautiously, preventing any over-tightening that could damage the components. Repeat this for all brackets, as consistency in the assembly will contribute significantly to achieving maximum solar energy efficiency.

4. ATTACHING THE SOLAR PANELS

Once the base is secure, the next step is to attach the solar panels to the brackets. This phase requires careful handling, as solar panels are both fragile and heavy. It is wise to have an extra pair of hands around to assist during this process. Align the solar panel with the attached brackets, ensuring that holes on the panel correspond with those on the brackets.

After proper alignment, use the securing screws included in the bracket kit. This step is essential, as loose fittings could lead to vibrations and potential failure of the solar panel setup. After attaching the panel, double-check each connection point for stability. Each screw should be tightened appropriately, ensuring that no panel is left unsecured. Investing time and precision in this phase guarantees reliability and longevity.

5. POSITIONING FOR OPTIMAL SUNLIGHT HARVESTING

To maximize solar energy absorption, the angle and orientation of the solar panels require careful consideration. Yuanneng brackets often allow for angle adjustments, which facilitate optimizing the solar panels’ position according to geographical locations. It’s crucial to follow guidelines on recommended tilt angles for the panels, varying with seasons and solar paths.

Utilizing a protractor or angle gauge can ensure accurate settings. If unsure, resources are available to provide angle recommendations based on the local climate. Once the desired angle is reached, securely fasten the brackets to prevent any movement. Adjustments should be systematic and thoughtful. Regular assessments of the panels’ orientation can yield significant energy production increases.

6. SAFETY AND REGULATORY CONSIDERATIONS

Safety must not be overlooked during solar bracket assembly. Anticipate potential hazards associated with handling heavy equipment and tools. Always wear personal protective gear, including gloves and safety goggles. It’s beneficial to have knowledgeable individuals assess safety guidelines when using ladders or performing work at elevated heights.

Understanding local regulations and codes regarding solar panel installation is equally paramount. Many jurisdictions enforce specific guidelines governing structural integrity, electrical work, and aesthetic considerations. Familiarizing oneself with local regulations before installing solar panels protects against potential fines and costly modifications post-assembly. Engaging a licensed professional, when necessary, ensures compliance and promotes safe installation procedures.

7. MAINTENANCE OF SOLAR BRACKETS

Post-installation, the sustainability of solar panels greatly depends on ongoing maintenance. Regular inspections of the brackets, screws, and panels are necessary to ensure that all components remain intact and functioning correctly. Check for signs of wear and corrosion, particularly if exposed to harsh environmental conditions. Cleaning the panels occasionally to remove debris and dust improves energy absorption. Adopting a preventive maintenance routine will extend the lifespan of the solar panel system significantly.

Establish a timeline for routine evaluations, perhaps once every few months or after adverse weather conditions. Collaborating with installation professionals may bring valuable insights into specific maintenance practices tailored to local climates. Documenting any observations during these evaluations will aid in timely repairs and will enhance system performance.

8. POTENTIAL CHALLENGES DURING ASSEMBLY

Various challenges may arise during the assembly process of Yuanneng solar brackets. Common obstacles include misalignment of panels and difficulty in securing brackets tightly. Such issues can result from inadequate preparation or hastiness in the assembly phase. Ensuring that the work area is well organized and that no components are overlooked can mitigate these challenges.

In cases where securing bolts become stripped or erratic, it might be necessary to replace these fasteners promptly. Using appropriate sizes and types of screws that match the manufacturer’s specifications is essential to avoid these issues. Employing a systematic approach and continuously assessing the work at various stages can effectively overcome such challenges and enhance the final assembly’s quality.

9. EVALUATING THE ASSEMBLY PROCESS

After completing the assembly, evaluating the entire process becomes essential. Conduct a walk-through of each step, assessing for any potential faults or areas of improvement. Identification of weaknesses in the assembly phase leads to more efficient practices for future installations. Encourage feedback from all participants involved in the assembly to gain diverse perspectives.

Documenting these evaluations not only benefits future projects but also contributes to a culture of continuous improvement. Over time, these records can reveal trends and patterns that warrant further investigation or optimization. Ultimately, thorough evaluations ensure the reliability and efficiency of the installed solar panel systems, which is vital to their long-term success.

FAQs

HOW LONG DOES IT TAKE TO ASSEMBLE A YUANNENG SOLAR BRACKET?

The duration required to assemble a Yuanneng solar bracket can considerably vary based on several factors. On average, with proper preparation and organization, the assembly may take anywhere from two to four hours. However, this timeframe can extend if additional panels are involved or particular structural adjustments are necessary. Moreover, working with a team can expedite the process significantly, as two or more pairs of hands reduce the time per task.

It is critical to allocate ample time during the assembly process. Rushing the installation may lead to mistakes or unsafe conditions that can compromise the efficacy of the solar panel system. Therefore, permitting adequate time ensures that each step is executed carefully and accurately, contributing to the longevity of the solar brackets.

CAN I ASSEMBLE YUANNENG SOLAR BRACKETS ALONE?

While it is technically feasible for one person to assemble Yuanneng solar brackets alone, the endeavor may become quite challenging, particularly when handling larger solar panels or complex installations. Having an additional person assists not just with lifting and positioning but also provides an extra set of eyes to ensure everything aligns correctly during the assembly.

Safety is another consideration; some parts may require secure placement or reaching high elevations safely. Collaborating with a colleague or helper promotes safe practices, allowing for a more efficient and manageable assembly process. Therefore, while independence in assembly is commendable, enlisting help can significantly enhance safety and efficiency.

WHAT TO DO IF A COMPONENT IS MISSING OR DEFECTIVE?

Encountering a missing or defective component during the Yuanneng solar bracket assembly can be disheartening, but it is essential to act promptly. First, thoroughly assess the packaging and assembly area to ensure the component isn’t misplaced. Often, small pieces may become hidden within the packaging material or other items.

If the item remains absent, or if a defective part has been identified, contacting Yuanneng’s customer support is imperative. Most reputable companies offer replacement parts or support services to rectify assembly challenges. Ensure that you retain documentation, such as receipts or order confirmations, to facilitate easier resolution processes. Taking swift action can minimize unnecessary delays in installation.

Considering the assembly of a Yuanneng solar bracket involves a multi-step process that prioritizes precision and safety, adherence to guidelines is paramount. Each segment of the installation serves an integral role in the effectiveness of solar energy capture. Proper understanding of components, maintaining an organized workspace, and consistently adhering to safety protocols constitute foundational best practices. Continuous evaluations and maintenance further fortify the structure’s integrity, enhancing the overall functionality of the solar panels. By approaching the assembly with foresight and care, you ensure a successful and efficient solar energy system capable of delivering sustainable power for years to come.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-assemble-yuanneng-solar-bracket/