To assemble a solar street light circuit, one must consider several key elements including selecting the appropriate components, understanding the wiring connections, and ensuring the system is efficient and functional. 1. The initial step entails choosing suitable solar panels and batteries to match the energy needs of the light., 2. Properly connecting the charge controller is vital for battery protection., 3. The circuit connections must be accurately aligned to avoid malfunctions., 4. Testing the entire assembly is crucial before final installation to ensure its operation. A detailed understanding of each component fosters a successful assembly process.

1. COMPONENT SELECTION

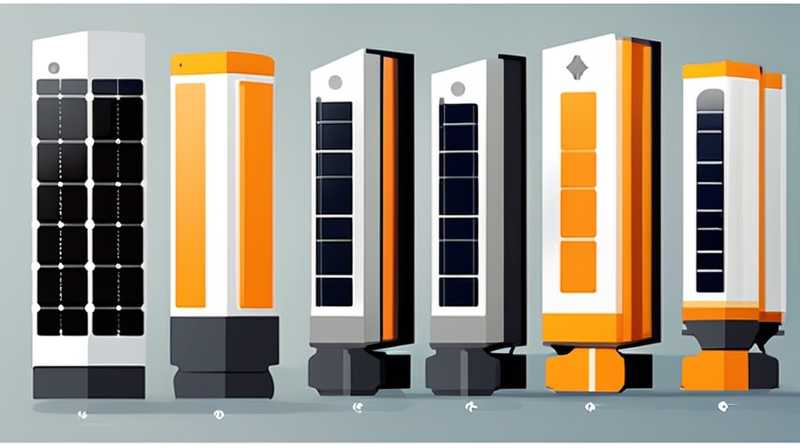

A successful solar street light circuit relies heavily on the appropriate selection of components. The primary components necessary for constructing the system include solar panels, batteries, charge controllers, LED lights, and wiring. Selecting the right solar panel is fundamental, as these panels harness energy from sunlight and convert it into electricity. Solar panels vary in efficiency, size, and voltage output; thus, the choice should match the anticipated energy consumption of the LED lights while considering local weather conditions.

Once the solar panel is selected, attention should be directed toward the batteries. Batteries serve as energy storage devices that power the lights during hours of darkness. The battery type should correspond to the chosen solar panel in terms of voltage and capacity. Lithium-ion batteries, for instance, offer higher energy density and longer lifespan, making them a favored choice in many solar applications. Alternatively, sealed lead-acid batteries may be more budget-friendly but could have a shorter lifespan and require more maintenance. Ultimately, ensuring the compatibility of each component enhances performance and longevity.

2. UNDERSTANDING WIRING CONNECTIONS

Having selected the necessary components, the subsequent focus should shift towards making the correct wiring connections. Proper wiring is crucial for ensuring the safe and efficient operation of the solar street light circuit. The wiring configuration involves connecting the solar panel to the charge controller, the charge controller to the battery, and finally, connecting the battery to the LED light fixture. Each connection must be completed with attention to detail to prevent disconnections, short circuits, and electrical hazards.

Connections typically involve utilizing connectors that can withstand outdoor conditions, such as weatherproof connectors. Conventional soldering or crimping techniques can be employed, though ensuring robust insulation is vital to prevent moisture ingress. Moreover, labeling each wire can greatly assist in troubleshooting future issues. Correctly insulating the wire joints using heat shrink tubing or electrical tape mitigates the chances of corrosion and increases durability against environmental factors. Detailed attention to wiring promotes operational safety and efficiency over the system’s lifecycle.

3. CHARGE CONTROLLER FUNCTIONALITY

Analyzing the role of the charge controller within the solar street light circuit is paramount. The charge controller acts as the brain of the system, regulating the energy flow between the solar panel, battery, and LED light. Its primary responsibilities include protecting the battery from overcharging and discharging, which can significantly affect its lifespan. Over time, neglecting proper charge controller installation can lead to battery damage and reduced performance.

Different types of charge controllers exist, including PWM (Pulse Width Modulation) and MPPT (Maximum Power Point Tracking). PWM controllers are simpler and more affordable but may not optimize energy usage as effectively as MPPT controllers. The latter type is designed for higher efficiency, extracting maximum power from the solar panel. The selection of the charge controller should thus be in alignment with energy needs and budget constraints. Following installation, calibration and configuration settings of the charge controller must be tailored to the specifics of the solar panel and battery utilized, ensuring seamless operation.

4. TESTING SEQUENCE

Once all components have been assembled, it is vital to engage in a thorough testing sequence. Testing ensures that all elements function cohesively, providing insight into any potential issues pre-installation. This stage involves verifying the voltage output of the solar panel under sunlight, testing the charge controller’s operation, and measuring the voltage across the battery to assess its charge levels.

Proper testing not only confirms that the components perform correctly but also helps in identifying any loose connections or faults that need rectification. A multimeter can be highly useful during this stage for measuring electrical parameters accurately. After initial testing, the LED light should also be activated to check its brightness and functionality. It is recommended to carry out these tests multiple times to confirm consistent performance under different conditions. Upon successful testing, the solar street light circuit can confidently be installed in its intended location, ensuring users benefit from an effective and reliable system.

5. INSTALLATION CONSIDERATIONS

The final phase involves carefully deciding on the installation site for the solar street light circuit. Site selection is key, as it must maximize sunlight exposure to the solar panel throughout the day. Factors such as surrounding trees, buildings, or other obstructions can significantly impact the panels’ efficiency. An ideal location should allow for sunlight unobstructed by shade during peak daylight hours.

Post site selection, it is necessary to secure the solar panel properly to ensure stability and durability against environmental factors. Utilizing poles made of resilient materials can aid in safeguarding the solar panels from harsh weather events, such as heavy winds or storms. Moreover, ensuring the LED light is mounted at an appropriate height guarantees optimal light distribution in the intended area. Conducting a post-installation performance evaluation is also recommended to confirm that the street light operates effectively, and adjustments can be made if necessary.

FREQUENTLY ASKED QUESTIONS

WHAT TYPE OF BATTERY IS BEST FOR SOLAR STREET LIGHTS?

Choosing the right battery for solar street lights significantly influences performance and longevity. Lead-acid batteries are commonly used, but advanced lithium-ion options are becoming increasingly popular due to their efficiency and lifespan. Lead-acid batteries are generally more affordable but have a shorter cycle life and require maintenance. Conversely, lithium-ion batteries offer higher energy density and faster charging times, making them suitable for longer use without frequent replacements. Assessing the energy needs of the installation and the budget will help in selecting the best battery type.

HOW LONG DOES A SOLAR STREET LIGHT LAST?

Solar street lights vary in longevity based on several factors, including component quality, maintenance, and environmental conditions. High-quality solar street lights can typically last up to 10 years or longer with proper care. The lifespan heavily depends on the durability of the solar panels, batteries, LED lights, and charge controllers used in the assembly. Regular maintenance efforts such as cleaning the solar panels and checking connections can significantly extend the operational life of the system. Factors like extreme weather and vandalism can also impact durability, making careful selection of materials and installation locations essential.

CAN SOLAR STREET LIGHTS WORK IN CLOUDY WEATHER?

Solar street lights can function effectively in cloudy or overcast conditions, though their performance may be reduced in terms of energy generation. Solar panels are designed to harness sunlight, including diffused sunlight on cloudy days, although the efficiency is generally lower than in direct sunlight. Many solar street lights are equipped with robust battery systems ensuring they store enough energy to operate efficiently during periods of low solar input. Additionally, advancements in solar technology have improved the ability to capture energy even on less sunny days, providing a reliable light source throughout varying weather conditions.

FINAL REMARKS

Assembling a solar street light circuit represents a blend of art and science, necessitating meticulous attention to detail and thoughtful evaluation at each stage. The comprehensive process encompasses component selection, wiring expertise, understanding charge controllers, thorough testing, and strategic installation. Each facet interlinks with the others, making it imperative to grasp how decisions in one area might influence the overall system functionality. Establishing a balance between component quality, environmental considerations, and intended application can lead to a successful assembly, offering a sustainable solution for public and private lighting needs.

Effective assembly promotes not only operational efficiency but significantly enhances durability against the elements and time. Moreover, addressing common questions about material selection, lifespan, and performance under various conditions ensures users make informed choices tailored to their specific needs. Ultimately, the pursuit of a reliable solar street light system contributes toward sustainability and energy conservation goals, reflecting a growing preference for environmentally friendly energy solutions. Through devoted attention to each detail in the assembly process, one can cultivate an effective solar street lighting system that stands the test of time while serving its intended purpose.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-assemble-the-solar-street-light-circuit/