Assembling solar lanterns involves several straightforward steps that require careful attention to detail and adherence to safety protocols. 1. Required components, including solar panels, LED lights, and battery packs, must be gathered. 2. Toolkit preparation involves essential tools such as screwdrivers and pliers, which ensure efficient assembly. 3. Adherence to manufacturer instructions is crucial as it guarantees optimal performance of the lantern. 4. Testing the assembled lanterns should follow assembly to confirm that they function properly and provide adequate light. Pay particular attention to how the solar panel is positioned to maximize sunlight absorption.

1. REQUIRED COMPONENTS

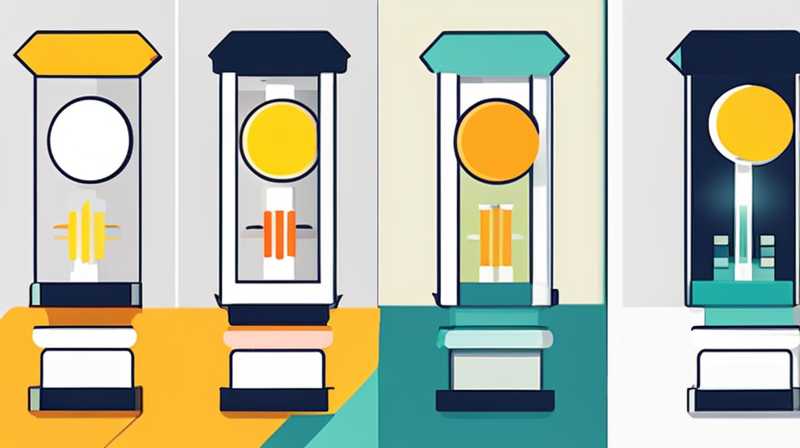

To successfully create solar lanterns, understanding and preparing the necessary components is vital. Each lantern typically consists of solar panels, LED lights, and battery packs. The solar panels convert sunlight into electrical energy, while LED lights serve as the source of illumination. Battery packs store the solar-generated energy, enabling the lanterns to function during hours of darkness.

Starting with the solar panels, these devices are comprised of photovoltaic cells that capture sunlight. They should be of high quality to ensure durability and efficiency. When selecting LED lights, choosing highly efficient options will significantly reduce power consumption while providing ample brightness. Lastly, battery packs are integral, ensuring that the lantern has enough stored energy to illuminate effectively at night.

In addition to these main components, implementing various accessories can enhance functionality. For instance, incorporating switches allows users to control the lighting levels or activate the lanterns only when necessary, prolonging battery life. Furthermore, including casings that provide protection against weather conditions—including rain and dust—extends the lifespan of the solar lanterns.

2. TOOLKIT PREPARATION

Equipping the right toolkit is crucial in the assembly process for optimal results. Essential tools typically include screwdrivers, pliers, and wire cutters. These instruments will aid in assembling parts securely and efficiently, impacting the lantern’s overall performance.

When sourcing tools, consider investing in a multitool that encompasses various screw heads, since solar lanterns may come with differing screws for attachment. A soldering iron becomes necessary if joining wires necessitates a secure connection that ensures durability. Having these tools organized and accessible will facilitate the assembly process and significantly reduce the assembly time.

Organizing the workspace is equally important. Allocate a designated area with ample lighting to minimize the likelihood of accidents. Keeping components separated and within reach can enhance efficiency, ensuring that one can focus solely on assembly. Additionally, having a guide or a reference manual available helps prevent missteps during the process.

3. ADHERENCE TO MANUFACTURER INSTRUCTIONS

Following the manufacturer’s instructions is imperative when assembling solar lanterns. Each product may contain unique designs and specifications, necessitating complete attention to detail outlined in the instructions. The manufacturer typically provides an assembly guide, which includes diagrams and specific steps to follow.

Carefully reviewing the assembly guide allows for a better understanding of how each component integrates to create a functional lantern. Verify that every part required is present before commencing assembly to avoid unnecessary interruptions. In cases where confusion arises from language translation, utilizing translation tools can clarify instructions and facilitate a smoother experience.

Additionally, safety precautions mentioned in the guide must never be overlooked. Some components, especially for electric assembly, could pose hazards if mishandled. Ensuring that work areas are free of distractions can prevent negligence and foster a secure environment for assembly.

4. TESTING ASSEMBLED LANTERNS

Once the assembly is complete, thorough testing becomes essential to confirm functionality. This process begins with checking each component’s connections and ensuring no loose wires exist. Notably, the solar panel’s positioning affects energy absorption, so adjustments may be needed for optimal sunlight exposure.

Conducting a test by placing the lantern in direct sunlight during the day allows the solar cells to charge fully. Verify how the lantern operates when evening approaches, ensuring that the LED lights illuminate as expected. Monitoring the performance through several evenings will provide insight into the battery’s longevity and help identify any potential issues early on.

If discrepancies arise, such as dim lighting or malfunctioning parts, revisiting the assembly with a focus on the instructions is essential. This diligence ensures that the lanterns function optimally and can be relied upon for their intended uses.

COMMONLY ASKED QUESTIONS

HOW LONG DOES IT TAKE TO ASSEMBLE SOLAR LANTERNS?

Assembling solar lanterns can vary significantly based on the complexity of the design and the skill level of the assembler. For most DIY setups, allocating one to three hours is reasonable, depending on the individual’s familiarity with the components involved. Detailed instructions streamline the process, allowing assembly to occur without excessive frustration or confusion.

Moreover, collecting all the necessary tools and components in advance can contribute notably to the efficiency of the assembly process. Pre-assembly preparation can mean the difference between a smooth, uninterrupted experience and one fraught with interruptions or lost time in searching for items.

For beginners, the task may require more time, especially while learning to handle tools properly and understanding how components fit together. Over time, as one gains experience, the speed of assembly will dramatically improve.

WHAT CAN CAUSE SOLAR LANTERNS TO MALFUNCTION?

Multiple factors can contribute to the malfunction of solar lanterns. A primary cause often lies in the solar panel’s exposure to sunlight; if the panel is obstructed by debris, dust, or other environmental factors, its efficiency diminishes drastically. Regular cleaning of the panel’s surface will improve performance significantly.

Another issue might arise from the battery’s longevity. Over time, batteries may suffer from reduced capacity due to repeated charging and discharging cycles. Replacing batteries as they degrade ensures continued functionality once the original power source no longer retains a charge.

Wiring issues may also lead to malfunctions. Loose or damaged connections can prevent electrical energy from flowing efficiently throughout the lantern. Regular inspections of wiring and soldered joints will help identify and rectify problems before they escalate.

HOW DO I MAINTAIN SOLAR LANTERNS?

Maintaining solar lanterns is integral for ensuring longevity and optimal performance. Regular cleaning of the solar panels to remove dirt, dust, or debris is vital, as these elements can inhibit efficient energy absorption. A soft cloth and mild cleaning solution are typically sufficient to restore the panel’s functionality.

Additionally, periodically inspecting the battery will allow for the early identification of decline in performance. Certain batteries degrade faster than others; noting signs of swelling or leakage can indicate when replacement is necessary. Moreover, if the lantern is not exposed to sunlight for extended periods, charging it occasionally ensures battery health.

Finally, protecting the lanterns from harsh weather conditions is advisable, especially if the devices are used outdoors. Storing them in a sheltered space during extreme weather can prevent damage to components, ensuring that they remain functional and ready for use whenever needed.

The art of assembling solar lanterns demands precise attention to every detail throughout the entire process. By focusing on essential components, utilizing the right tools, adhering strictly to the assembly instructions provided by the manufacturer, and carrying out thorough testing after assembly, one can ensure the creation of a reliable and efficient solar lantern. This venture into renewable energy not only minimizes reliance on traditional electrical sources but also promotes sustainability and environmental awareness, making it a rewarding experience. Successfully crafted solar lanterns can provide ample illumination during nighttime, enhancing outdoor experiences while contributing to energy conservation efforts.

Furthermore, embracing the challenges that arise during assembly fosters problem-solving skills and resourcefulness in tackling unexpected issues. For those encountering difficulties, seeking guidance through online resources, tutorials, or expert opinions can bridge gaps in knowledge and simplify the learning curve. Ultimately, mastering solar lantern assembly serves not just as a beginner’s project but can ignite a passion for embracing more sustainable living practices in various aspects of daily life. Engaging in solar technology positions individuals to become not only proficient DIYers but also advocates for cleaner and more sustainable energy solutions. As reliance on fossil fuels continues to present ecological challenges, investing energy and effort into assembling solar lanterns marks a significant step in nurturing environmental stewardship and fostering a brighter future for generations to come.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-assemble-solar-lanterns/