Assembling a solar black pipe joint involves a series of precise steps to ensure functionality and efficiency in solar water heating systems. 1. Gather necessary materials, 2. Cut black pipes to required lengths, 3. Apply appropriate adhesive, 4. Fit joints securely, 5. Allow adequate curing time. The most critical step is applying the adhesive properly; this secures the joint and prevents leaks. Not overlooking the importance of using compatible materials is essential, as different types of plastics react differently to various adhesives, which could compromise the integrity of the system. In the solar heating context, ensuring the proper assembly of the joints is crucial as it directly impacts system performance and longevity.

1. UNDERSTANDING SOLAR BLACK PIPE JOINTS

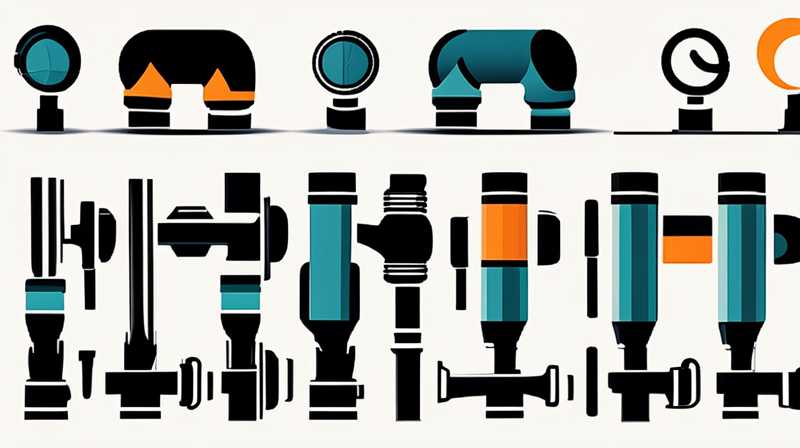

Solar black pipe joints are pivotal components in solar water heating systems, allowing for the effective transport of heated water. Understanding their assembly is vital for optimal functionality. The materials used and the process of assembling these joints can significantly impact overall system performance and efficiency.

The primary purpose of black pipe joints is to connect pipes that carry hot water from solar collectors to storage tanks or distribution systems. These joints need to be robust, heat-resistant, and impermeable to prevent any leaks that would compromise energy transfer and system efficiency. Therefore, the materials and techniques used in their assembly warrant thorough examination to ensure that they meet the necessary standards.

The construction of solar black pipe joints typically involves materials such as high-quality PVC or CPVC, which are both efficient in heat transfer and resistant to corrosion. An understanding of the specific requirements of your solar heating system will dictate the exact materials used. Proper assembly is not simply about connecting pipes; it is essential to consider thermal expansion, pressure compatibility, and the joint layout, which can alter heat dynamics within the system.

2. TOOLS AND MATERIALS REQUIRED FOR ASSEMBLY

Before embarking on assembling solar black pipe joints, having the right tools and materials is crucial. Essential tools include pipe cutters, deburring tools, solvent cement, and appropriate protective gear. Each of these tools plays a significant role in ensuring that the pipes fit together correctly and that the connections are sealed against leaks.

Pipe cutters are designed to create clean, precise cuts, minimizing the risk of burrs or jagged edges. Jagged edges can lead to improper fitting of joints, which may compromise the entire system. After cutting, using a deburring tool ensures that any rough edges are smoothed out, making it easier for the adhesive to create a strong bond. It’s vital to also have protective gear, such as gloves and goggles, to safeguard against accidental burns or chemical exposure during the assembly process.

The choice of materials is equally important. Using high-quality black pipes specifically designed for solar applications, along with compatible adhesives, is necessary to maintain efficiency and durability. Selecting materials resistant to UV and extreme temperatures will ensure longevity, reducing the need for frequent repairs or replacements. Reliable equipment and quality materials lay a strong foundation for a functional solar heating system.

3. CUTTING AND PREPARING THE PIPES

Cutting and preparing the black pipes is a crucial step that sets the stage for effective joint assembly. Precision in this phase cannot be overstated. When cutting pipes, ensuring that they are cut to the correct lengths that fit your system layout will prevent unnecessary strain on joints and fittings.

After measuring and cutting the pipes, the preparation process involves deburring the edges. Deburring is essential as it removes any sharp edges or debris that might interfere with the joint connection. A clean edge also enhances the bonding surface area for adhesive, which is vital for creating a secure joint. This preparation stage may seem minor, but it directly influences the integrity of the entire system.

Furthermore, it is advised to clean the cut edges with a cleaner appropriate for the materials used. Ensuring that the surfaces are free from contaminants such as dirt, oils, or moisture will promote better adhesion. A clean surface allows the joint to come together more securely, minimizing the risk of leakages and ensuring that the system operates as intended.

4. APPLYING SOLVENT CEMENT AND ASSEMBLING JOINTS

The application of solvent cement is a critical phase in assembling solar black pipe joints. Using the correct adhesive is paramount for a sturdy bond and leak-proof joints. The process begins with the careful application of the solvent cement on the inside of the fitting and the outside of the pipe, ensuring that each part is adequately coated.

It’s important to act quickly once the adhesive has been applied, as most solvent cements have a limited working time. After applying the adhesive, the pipe should be inserted into the fitting with a rotating motion to evenly distribute the cement, leading to a stronger bond. This step helps in ensuring that the adhesive penetrates well and adheres to the surfaces effectively.

Once the joint is assembled, allowing adequate curing time is essential before subjecting it to any pressure or water flow. Curing times can vary by product; hence, adhering to the manufacturer’s guidelines is critical for the longevity of the joint. Rushing this process can lead to weak bonds that may fail under thermal and pressure stress during system operation.

5. TESTING THE ASSEMBLY

After assembling the solar black pipe joints, testing is a necessary step to ensure the system’s integrity. Conducting a pressure test verifies that the joints are sound and leak-free. This test involves applying pressure to the system, often with water or air, to check for leaks and ensure that the assembly can withstand operational conditions.

For a water system, pressure testing usually requires filling the pipes with water and then pressurizing. Monitoring any visible connections during this process is vital; if water leaks from joints, adjustments may be needed to either reapply adhesive or replace the fitting altogether. For air pressure tests, ensure that all joints are sealed before applying air pressure to the system, as this can reveal less visible leaks.

It is prudent to perform these tests before the system is put into operation to avoid potential failures that may lead to damage or inefficiencies. Successful completion of this testing phase will guarantee that your solar black pipe joint assembly can handle the expected thermal dynamics and operational pressures effectively.

6. MAINTAINING SOLAR BLACK PIPE JOINTS

Maintenance is an ongoing requirement to ensure that solar black pipe joints continue to function efficiently over time. Regular inspections play a crucial role in identifying issues before they escalate. This includes checking for visible wear and tear, signs of leaks, or damage due to thermal expansion.

If a problem is detected, addressing it promptly is key to maintaining the system’s efficiency. Common maintenance tasks may include tightening loose connections or replacing fittings that have worn down due to stress or environmental factors. Taking proactive measures can extend the lifespan of the assembly and improve system performance.

Additionally, keeping the system clean and free from debris can mitigate risks associated with blockages and pressure accumulation. Regular checks on the condition of insulation around the joints can also be beneficial, as insulation helps regulate temperature and prevent losses during colder months.

Lastly, documenting maintenance activities can help track the performance of the system and assist in identifying any recurring issues. This level of attention ensures that the solar heating system operates effectively while maximizing energy efficiency in the long run.

FREQUENTLY ASKED QUESTIONS

WHAT MATERIALS ARE REQUIRED FOR ASSEMBLING SOLAR BLACK PIPE JOINTS?

The assembly of solar black pipe joints requires specific materials to ensure durability and efficiency. Primary materials include high-quality black pipes made from either PVC or CPVC, a suitable solvent cement designed for these materials, and fittings compatible with the pipe dimensions. The selection of materials should account for thermal resistance and UV stability, essential for solar applications.

In addition, tools such as pipe cutters, deburring tools, and protective gear—gloves and goggles—are pivotal to ensure safety and precision during assembly. The effectiveness of the assembly process hinges on using compatible materials that withstand pressure and the operating temperature of the system. All components must adhere to the required standards to prevent any operational inefficiencies or failures.

HOW DO I DETECT A LEAK IN MY SOLAR BLACK PIPE JOINT?

Detecting a leak in solar black pipe joints involves a few strategic steps. Begin by visually inspecting all joints and connections for signs of moisture or water pooling, as these indicate potential leak points. Conducting a pressure test by filling the pipes with water and then monitoring for leaks is another effective method to identify problematic areas.

Another approach is to use a specialized leak detection solution. This involves applying the solution to the joint and observing for bubbles, which indicate the presence of escaping air or water under pressure. This method is particularly useful for identifying tiny leaks that may not be visible to the naked eye.

Ensuring that the system is turned off and allowed to cool before conducting these tests is crucial, as thermal expansion may prevent accurate detection. By staying vigilant and regularly checking the integrity of the system, you can effectively manage and mitigate potential issues that arise from leaks in solar black pipe joints.

HOW OFTEN SHOULD I MAINTAIN MY SOLAR BLACK PIPE JOINTS?

The frequency of maintenance for solar black pipe joints is subject to several factors, including the environmental conditions and the operational intensity of the system. As a general rule, a thorough inspection should occur at least twice a year to ensure that all joints and connections are secure and free from damage.

Regular observing of the system during seasonal transitions is also wise, particularly before and after winter months when temperature changes can impact joint integrity. If the system operates under high pressure or in variable temperatures, quarterly maintenance checks may be prudent to mitigate the risks of leaks or joint failures.

Documenting maintenance activities aids in identifying trends regarding joint performance and helps forecast when more detailed examinations may be needed. Overall, staying proactive about maintenance will contribute significantly to the system’s longevity and operational efficiency.

In summation, assembling solar black pipe joints is a systematic process involving precise steps that must be followed to ensure a durable, leak-proof installation. Critical actions include gathering appropriate materials, understanding the role of each component, cutting and preparing the pipes, applying adhesives with expertise, and testing the assemblies post-construction. Regular maintenance ensures that the system continues to operate effectively, maximizing its performance, efficiency, and longevity. Future considerations should involve staying informed about advancements in materials and techniques, as improvements can often lead to enhanced system performance. This knowledge is crucial for anyone engaged in the crafting and upkeep of solar water heating systems, promoting both sustainability and energy efficiency in the long term. Engaging in continual education around best practices, technology, and methodologies will solidify your capability in effectively assembling and maintaining solar black pipe joints.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-assemble-solar-black-pipe-joint/