1. Assembling a solar valve involves several critical steps that require careful attention to detail, preparation, and tools.

2. First, ensure you have the necessary components and tools for assembly.

3. Third, follow the manufacturer’s instructions rigorously. Make sure to double-check connections to maintain system integrity.

4. Fourth, test the assembled valve for leaks and proper function once the installation is complete.

The process of assembling a solar valve demands precision and understanding of both the components and the specific requirements dictated by the system’s design. Given the growing emphasis on renewable energy solutions and the efficient harnessing of solar power, utilizing a solar valve systems becomes increasingly relevant.

1. UNDERSTANDING THE COMPONENTS

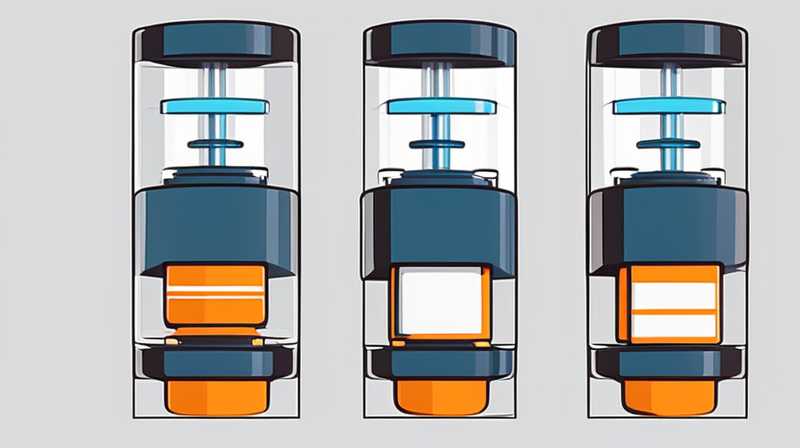

In order to assemble a solar valve correctly, a thorough understanding of the components involved is paramount. A solar valve typically consists of a few essential parts: the valve body, actuator, and various control mechanisms. Each element plays a crucial role in ensuring that the valve functions appropriately within the solar energy system. The details provided in the manufacturer’s instructions can significantly simplify the assembly process by clearly outlining the specifics of each component.

Having a precise comprehension of how these components interact can lead to more effective assembly techniques. For instance, the valve body serves as the main structure where the flow of the heat transfer fluid occurs, while the actuator controls the opening and closing mechanism based on temperature or pressure changes in the system. Moreover, understanding how these parts fit together creates a foundational knowledge that allows a smooth assembly experience.

When embarking on the assembly of a solar valve, it is essential to gather all necessary materials first. The importance of possessing the proper tools cannot be understated as they facilitate each step. Common tools may include wrenches, screwdrivers, and sealant, among others. Comprehensive preparation will expedite the assembly process and minimize the potential for errors.

2. PREPARING FOR ASSEMBLY

Preparation involves not only gathering tools but also conducting a thorough inspection of each component. Ensure that the valves, fittings, and seals are free from damage or wear and conform to the specifications required by the system. This step is essential as any defects can lead to inefficiencies or failure in the solar system’s performance.

Understanding local codes and regulations about solar installations is another critical aspect of preparation. Many regions have specific guidelines governing the installation of solar energy components to ensure safety and sustainability. Familiarizing oneself with these regulations can prevent future complications, including fines or the need for modifications after installation.

Once components are inspected and tools are prepared, the workspace should be organized to facilitate a smooth assembly process. A clean, clutter-free environment reduces the risk of losing components. It also helps in maintaining focus, which is paramount when dealing with small pieces that require precision.

3. ASSEMBLY STEPS

With preparation complete, the assembly process begins. The first step typically involves securing the valve body in place. Many valves utilize a set of screws or bolts to affix the body to the solar system framework securely. It’s important to achieve proper torque specifications outlined by the manufacturer to prevent leaks and ensure durability.

After securing the valve body, the next action is to install the actuator. This actuator may be electronic or mechanical and needs to be attached according to the design provided in the specifications. Make sure that the actuator is oriented correctly for optimal performance. Any misalignment during assembly can lead to performance issues down the line.

Additionally, connecting the control mechanisms is essential for the operational functionality of the valve. Wiring the electrical components, for example, necessitates adherence to strict electrical codes and safety guidelines to prevent hazards. Each wire should be secured and insulated correctly to allow for safe energy transfer from the solar collector to the valve and beyond.

4. CALIBRATION AND TESTING

Once the assembly is completed, the next phase involves calibration. A well-calibrated solar valve ensures that it opens and closes at the correct temperatures, enhancing the system’s efficiency. Follow the manufacturer’s instructions to calibrate the valve properly. This often involves testing the valve in the operational environment to ensure accurate response.

Testing should also include inspecting all connections for leaks. A simple visual inspection followed by a pressure test can help identify any issues that may not be immediately visible. If leaks are detected, one must re-tighten connections or replace damaged seals to ensure a complete seal.

Moreover, it is advisable to monitor the valve’s performance over time. Introducing a regular maintenance schedule can significantly extend the lifespan of the valve and improve the overall efficiency of the solar energy system. Keeping detailed records helps identify patterns and potential problems early.

5. TROUBLESHOOTING COMMON ISSUES

In some instances, assembling a solar valve may not go flawlessly, and it’s important to recognize common issues. One prevalent problem involves improper alignment, which can cause the valve to malfunction and impact energy efficiency. If issues arise, thorough troubleshooting steps should be taken.

One critical aspect of addressing alignment issues is to review the assembly instructions and ensure that all components are appropriately positioned. Unbolt and readjust if necessary, taking care to follow torque specifications to prevent further complications.

Another common problem pertains to electrical connections. Issues may arise from loose or damaged wiring that can lead to erratic valve behavior. Inspecting electrical connections regularly ensures safe operation and efficient functionality within the system.

6. MAINTENANCE INSIGHTS

Regular maintenance is a necessity to ensure the long-term success of the solar valve. To avoid issues in the future, it is advisable to conduct annual inspections to check for leaks, wear, and proper function. Ensuring that all components remain in optimal condition enhances system efficiency and lifespan.

Additionally, seasonal checks can be beneficial, especially before peak usage periods. These checks can help identify risks associated with environmental factors, such as extreme weather conditions, that might affect the valve’s functionality. As a result, being proactive with maintenance can prevent significant issues from arising.

Keeping a maintenance log is prudent. This log can record inspections and repairs over time, assisting in identifying trends and potential future issues. Proactive maintenance ultimately ensures a reliable and efficient operation of the solar energy system.

7. COST-EFFECTIVENESS OF ASSEMBLY AND MAINTENANCE

From a financial perspective, assembling a solar valve can be a cost-effective measure. Doing the installation oneself, if a certain level of skill exists, can lead to savings in labor costs. It is also beneficial to compare costs and options available in the market when purchasing components to ensure that quality is maintained without overspending.

Investing time in proper assembly and maintenance generally leads to reduced long-term costs associated with repairs and replacements. Evaluating costs associated with potential downtime due to malfunctioning valves emphasizes the importance of proper assembly and ongoing maintenance. Doing it right the first time saves money and ensures reliable performance from the solar energy system.

8. ENVIRONMENTAL IMPACT AND EFFICIENCY

Finally, the environmental benefits of a well-assembled and maintained solar valve are substantial. Properly functioning solar systems reduce reliance on fossil fuels and enhance the usage of renewable energy sources. An efficiently operating solar valve is pivotal in maximizing the energy harnessed from the sun.

Using renewable energy sources not only diminishes carbon footprint but also promotes sustainability. As society transitions towards clean energy solutions, enhancing system efficiency becomes crucial. Optimally functioning solar valves contribute measurably to this shift and encapsulate the broader vision of a sustainable future.

FREQUENTLY ASKED QUESTIONS

WHAT TOOLS ARE NEEDED FOR ASSEMBLING A SOLAR VALVE?

When preparing to assemble a solar valve, a variety of tools will be necessary. Commonly needed tools include wrenches of various sizes, screwdrivers, and pliers. Utilizing a torque wrench may also be essential in order to achieve the correct tightness in connections as specified by the manufacturer’s guidelines. Other helpful items are sealants to ensure a leak-free assembly, operational manuals for reference, and possibly a multimeter for checking electrical connections if the actuator is electrically controlled. Furthermore, it is wise to have safety equipment, such as gloves and safety glasses, on hand to ensure safe handling of components during assembly. Proper organizational methods for the tools can help streamline the assembly process, thus making the task more efficient.

HOW CAN I TEST THE SOLAR VALVE AFTER ASSEMBLY?

Upon completion of the assembly, multiple testing methods can gauge the function of the solar valve effectively. One critical test is a pressure test, which verifies that all connections are tight and do not leak under pressure. To execute this test, the system should be filled with fluid, and pressure should be monitored closely, ensuring it remains stable without any drop.

Another essential testing method involves ensuring that the actuator responds appropriately to changes in temperature or pressure. This can typically be achieved by simulating the conditions under which the valve is designed to operate. Observing the valve’s operation during these simulations provides insight into its efficiency and functionality. Moreover, regular monitoring over time can help in recognizing any gradual declines in performance, allowing for proactive maintenance measures to be implemented.

WHAT ARE COMMON MISTAKES MADE DURING ASSEMBLY?

Several common pitfalls typically occur during the assembly of solar valves. One prevalent mistake is failing to follow the manufacturer’s guidelines carefully. Ignoring specific recommendations regarding torque settings and component alignment can lead to inefficiencies and damage to the system. It is imperative to ensure that all fittings and seals are appropriately tightened and aligned; improper installation can result in leaks or malfunctions.

Another mistake includes neglecting electrical safety protocols during assembly. Electrical components must be properly insulated and securely attached to prevent hazards. Additionally, many individuals may overlook the importance of pre-assembly inspections, which can uncover potential issues before they manifest during operation. Attention to detail throughout the assembly process greatly contributes to the successful operation of solar valve systems.

Assembling a solar valve requires meticulous attention, knowledge of components, and adherence to guidelines to ensure optimal operation. Engaging in proper preparation and execution leads to increased efficiency in solar systems, aligning with broader environmental goals. Mastering the assembly process not only enhances personal skill sets but also contributes positively to the sustainability movement and promotes better energy solutions. Furthermore, ongoing maintenance and regular checks ensure that the systems continue to perform well over time. By understanding the complexities involved in solar valve assembly and maintenance, individuals contribute to a more sustainable future while enjoying the benefits of reduced energy costs and environmental impact.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-assemble-a-solar-valve/