Assembling a solar car can be an exciting and educational project that not only fosters creativity and engineering skills but also promotes awareness of renewable energy sources. 1. Determine the necessary materials and tools, 2. Understand the components of the solar car, 3. Follow a structured assembly guide, 4. Test and troubleshoot the completed vehicle. A detailed explanation of each step is essential for a successful build. This process involves meticulous planning and execution, ensuring that all components work together harmoniously to create a functioning solar-powered vehicle.

1. UNDERSTANDING COMPONENTS OF A SOLAR CAR

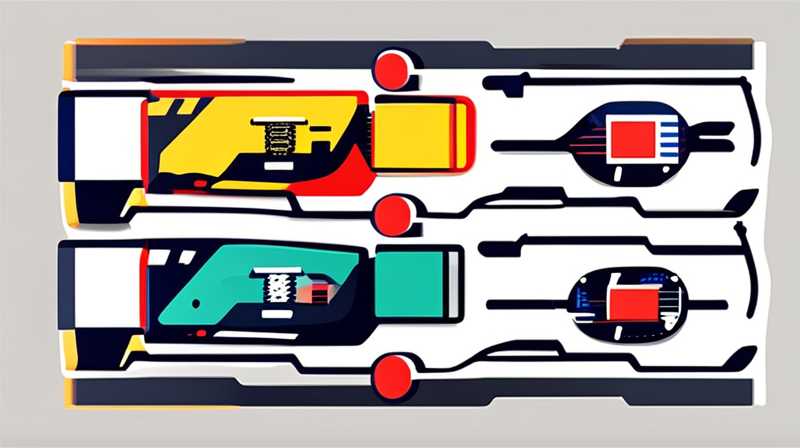

Before embarking on the assembly process, gaining a comprehensive understanding of the essential components required for crafting a solar car is indispensable. At the heart of the operation lies the solar panel, which converts sunlight into electrical energy. This energy then powers the motor, facilitating the movement of the vehicle. Alongside these crucial parts, the chassis serves as the foundational structure, providing stability and support as the car moves.

Furthermore, the wheels play a significant role in mobility, with their design directly influencing performance. The battery is typically included to store excess energy produced during sunny conditions, enabling operation even in low-light situations. To effectively integrate these components, having a clear grasp of their function helps facilitate smoother assembly, thereby minimizing errors or complications during the subsequent construction phase.

In addition, it’s prudent to outline the tools required for the task. Basic hand tools, including screwdrivers and pliers, along with adhesives or fasteners, will be essential for securing different elements of the car together. Having a good workstation equipped with ample lighting will enhance comfort and precision throughout the assembly process.

2. GATHERING MATERIALS AND TOOLS

Proceeding to the next stage, discovering the appropriate materials and tools is paramount for effective assembly. This involves sourcing the highest quality solar panels, motors, and batteries that align with the specific design requirements of the solar car. Opting for lightweight materials, such as plastic or aluminum, for the chassis can greatly improve speed and efficiency by reducing the overall weight of the vehicle.

It is advisable to purchase a solar car kit if one is available, as these kits typically include all necessary components along with detailed instructions. This route can simplify the process, particularly for beginners. For individuals seeking a more customized approach, assembling parts from various sources can offer greater flexibility in design choices. However, this route necessitates meticulous planning to ensure compatibility among picked components.

The list of tools typically includes a soldering iron for creating secure electrical connections, a multimeter for checking circuitry, and various hand tools for assembly. Weighing practical options for tool selection can save time and enhance the efficiency of the entire project, as employing the right tools minimizes complications during assembly.

3. FOLLOWING THE ASSEMBLY GUIDE

With all components gathered and a clear understanding of each piece’s role in the solar car, navigating through the assembly guide is crucial. Initiating the process often begins with the chassis, providing a strong framework upon which the rest of the vehicle is developed. Careful alignment of components during this phase can prevent issues later in the project.

Following the fixation of the chassis, attention shifts to the installation of the wheels and motor. Ensuring that these parts rotate smoothly is essential for optimal performance. An important tip is to double-check the axle alignment, as improper orientation can lead to significant mechanical failure.

Once the motor is securely connected, the focus will turn to attaching the solar panel. Correct positioning is vital to ensure maximum sunlight exposure, enhancing the panel’s ability to generate energy. This part of the assembly often involves soldering wires to establish a safe connection to the motor and battery, thus enabling energy transfer as sunlight stimulates the panel.

Each phase in this assembly process demands thorough attention, as oversight can lead to functional deficits in the final product. By maintaining focus and following the guide, the assembly of the solar car can proceed smoothly with fewer potential complications.

4. TESTING AND TROUBLESHOOTING

Upon completion of the assembly, the next essential step involves testing the solar car to ensure all components function correctly. This phase allows builders to experience firsthand the fruits of their labor while determining if any adjustments are necessary. To start the testing process, place the car in direct sunlight and observe its ability to move. A functional solar car should glide smoothly and respond well to sunlight, showcasing the effectiveness of its engineering.

Troubleshooting may uncover various issues, such as insufficient movement, which could stem from inadequate power supply, misaligned components, or even poorly connected wiring. In such instances, checking the connections to the solar panel, motor, and battery is of utmost importance. Employing a multimeter can assist in verifying if voltage is being adequately supplied to the motor.

If difficulties persist, reevaluating each part’s compatibility with other components may reveal hidden incompatibilities or errors in the assembly. This investigative process tailored towards problem-solving encourages learning and can significantly improve one’s technical skills regarding engineering and renewable energy.

FREQUENTLY ASKED QUESTIONS

WHAT IF MY SOLAR PANEL IS NOT GENERATING POWER?

If you find that the solar panel fails to generate power as expected, begin by examining the panel for obstructions that might block sunlight. Dust or debris can hinder performance significantly. Furthermore, inspecting the wiring connections should be a priority. Loose or frayed wires can prevent energy transfer to the battery or motor. If the wiring appears intact, utilizing a solar panel tester or multimeter can help determine if the panel itself is functioning correctly. Taking these steps should help identify the source of the problem, allowing for targeted troubleshooting and timely solutions.

HOW LONG DOES IT TAKE TO ASSEMBLE A SOLAR CAR?

The time required to assemble a solar car varies greatly depending on the complexity of the design and the builder’s skill level. A basic kit with simple instructions can typically be assembled within a few hours, while more intricate designs may necessitate several days of meticulous work. Factors influencing assembly time include the preparation required, the thoroughness of the assembly guide, and any troubleshooting needed during the process. Thus, allocating ample time for both assembly and potential adjustments is prudent to ensure a successful and satisfying building experience.

CAN I USE A SOLAR CAR FOR TRANSPORTATION?

While constructing a solar car can be enticing, it is important to emphasize that such vehicles are primarily designed as educational tools and for hobbyists rather than practical transportation solutions. Most solar cars are lightweight models tailored for speed and efficiency in controlled environments, often utilizing smaller solar panels and motors suited for limited distance travel. Furthermore, the energy output of these models typically does not support longer trips or practical use in everyday settings. Hence, embracing solar vehicles as a learning experience or hobby rather than as a mode of transportation is advisable.

In summation, embarking on the assembly of a solar car represents an intriguing intersection of creativity and engineering that fosters a deeper understanding of renewable energy technologies. Mastering crucial components such as solar panels, motors, and batteries equips aspiring builders with insights into the mechanics of eco-friendly vehicles. Streamlined planning and the selection of appropriate materials are vital for successful execution. Additionally, adherence to a detailed assembly guide enhances structure cohesiveness. Testing the completed vehicle not only validates engineering efforts but also serves as a valuable learning experience regarding practical applications of solar power. Exploring this fascinating project can ignite enthusiasm for sustainable practices while honing technical skills that may prove beneficial in future endeavors. Each aspect, from initial preparation to rigorous testing, contributes meaningfully to a thorough grasp of solar car mechanics and the principles of renewable energy, thus inspiring future innovations within this critical field.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-assemble-a-solar-car-video/