To assemble a solar ball valve, one must follow specific steps to ensure proper functionality. 1. Gather all necessary components, 2. Understand the layout and mechanism, 3. Follow the assembly instructions carefully, 4. Test for leaks post-assembly. The assembly generally involves aligning parts correctly, tightening connections adequately, and ensuring all seals are in place. A detailed exploration of the process will facilitate a better grasp of each step, leading to successful assembly.

1. COMPONENTS REQUIRED

Before starting the assembly process, it is imperative to identify all necessary components. Tools and materials needed include a solar ball valve, appropriate fittings, sealing tape, a wrench, and possibly a lubricant for easier handling. Knowing what to gather before initiating the assembly will streamline the process.

Moreover, different models of solar ball valves may possess varying components, so consulting the specific manual related to the product is advantageous. This preparation phase can prevent delays and ensure a smoother assembly procedure.

Understanding each component’s role enables the assembler to comprehend how these parts will function together once the assembly is complete.

2. UNDERSTANDING THE MECHANISM

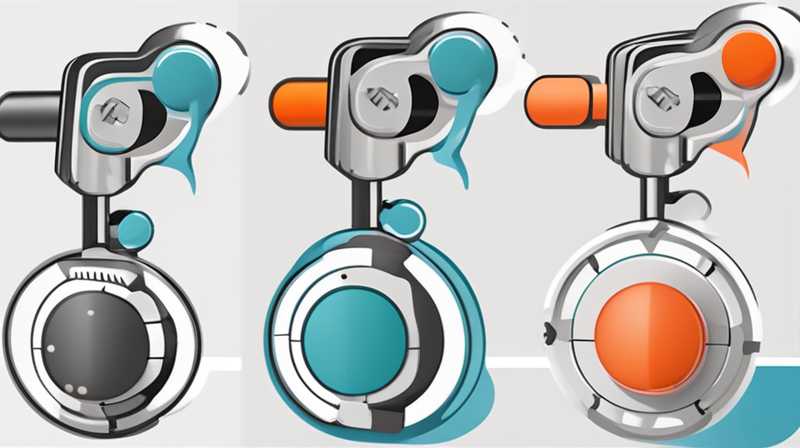

Prior to assembly, an understanding of how a solar ball valve operates is crucial. The primary function of a solar ball valve is to regulate the flow of fluids, which can range from water to various automotive liquids. It employs a spherical disc that rotates to open or close the valve, allowing fluid to flow only when desired.

By examining the internal mechanism, one appreciates the significance of the ball itself and how it aligns with the valve seat. When properly aligned, it creates a tight seal, preventing leaks. Conversely, a misaligned ball can lead to significant issues, including leaks or inadequate flow. Familiarizing oneself with these interactions ensures proper assembly later on, contributing to overall operational efficiency.

3. ASSEMBLY PROCESS

With components gathered and an understanding of the mechanism in place, the assembly can commence. The initial step involves attaching the valve to the designated piping. This requires careful placement to ensure all ends are compatible with existing piping systems. Often, this step includes using sealing tape to create a secure connection.

Following attachment, the next part involves aligning the valve’s internal components. The ball must be positioned accurately so that it can function without hindrance. This may require maneuvering or rotating until each piece aligns perfectly. Often, individuals will refer to diagrams provided in the manual to visualize the correct setup during this phase.

Another essential step in the assembly process is tightening connections appropriately. While it’s critical to achieve a tight seal, over-tightening can damage the components. Therefore, it is essential to use tools effectively, achieving the necessary grip without compromising integrity.

Once the connections are secure, the last aspect involves checking any seals used. Every connection point should be inspected meticulously for potential gaps or misalignments. This phase includes testing the valve’s movement to ensure there are no obstructions and that the ball rotates freely.

4. TESTING THE ASSEMBLY

Upon completion of the assembly, it is vital to conduct tests to confirm functionality. This step may involve turning on the water supply and observing for any leaks in the system. A slight increase in pressure can sometimes expose vulnerabilities that were not apparent during assembly.

Additionally, it is prudent to operate the valve through its full range of motion. Checking that the rod or handle operates smoothly will ensure that the ball is positioned correctly, facilitating a seamless user experience. Should any issues arise during testing, returning to the assembly for further adjustments is essential.

Moreover, understanding typical failure modes can provide insight into potential future issues. By anticipating these, one can troubleshoot effectively, ensuring long-lasting operation.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLAR BALL VALVE USED FOR?

A solar ball valve primarily functions to control fluid flow in systems associated with solar heating. Its design allows users to regulate the circulation of fluids, optimizing efficiency. This capability makes it suitable for various contexts, from residential water heating systems to complex solar thermal applications. Understanding its operation helps in maximizing energy savings and ensuring that heating cycles are appropriately managed.

HOW DO I KNOW IF MY SOLAR BALL VALVE IS WORKING PROPERLY?

Confirming the proper functionality of a solar ball valve requires careful observation. Look for signs such as leaks at connection points, which indicate insufficient sealing. Also, check the handle or lever for resistance; it should move easily without requiring excessive force. After conducting these checks, ensuring that the valve opens and closes smoothly without obstruction is crucial.

CAN I REPAIR A SOLAR BALL VALVE OR DO I HAVE TO REPLACE IT?

In many cases, repairing a solar ball valve can be an option. Inspect for specific issues such as worn seals or incorrect alignments, which might be rectified without needing replacement. However, significant damage, especially to the ball or housing, may necessitate a full replacement. Regular maintenance can significantly extend the lifespan of the valve, leading to enhanced efficiency in your solar heating system.

In summation, assembling a solar ball valve encompasses multiple steps, beginning with gathering essential components and proceeding through understanding the mechanism, initiating the assembly, and conducting thorough testing afterward. Several components come into play, such as the valve itself, ensuring proper seals, and understanding the flow of the fluids involved. Having detailed knowledge about each aspect can significantly contribute to a successful assembly, enhancing the efficiency of solar heating systems. Proper attention to detail throughout the assembly will not only ensure functionality but also mitigate future maintenance needs. Understanding how the system works and proactively monitoring it can yield significant benefits, including energy savings and prolonged equipment life. By prioritizing comprehensive evaluation at each step, one can facilitate a robust and efficient system that meets the demand of solar applications thoroughly.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-assemble-a-solar-ball-valve/