To assemble a mini solar panel, gather all necessary materials and tools, including solar cells, a soldering iron, wiring, and a frame. 1. Start by arranging solar cells in series or parallel depending on desired voltage and current, 2. Solder the cells together carefully to create a panel, 3. Connect the panel to a battery or charge controller for energy storage, 4. Encapsulate the panel to protect it from the elements. Each step must be executed with precision and care to ensure the panel functions effectively and safely. When constructed properly, a mini solar panel can generate renewable energy for various applications.

1. REQUIRED MATERIALS AND TOOLS

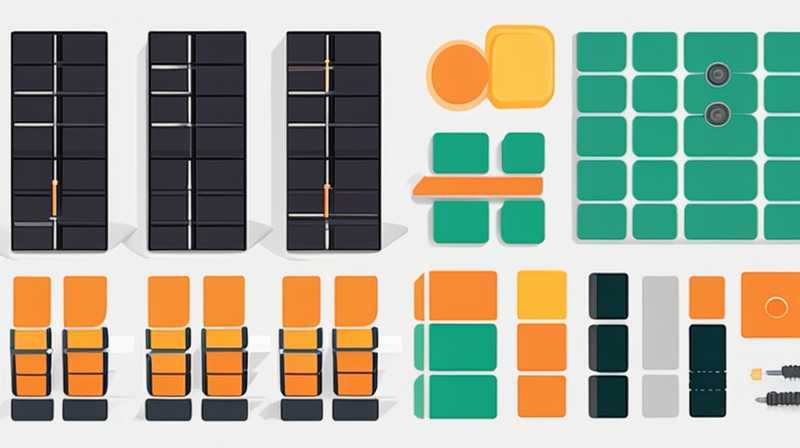

Constructing a mini solar panel requires an array of specific materials and tools. The most crucial item is the solar cells themselves, which are the foundation of solar technology. These units convert sunlight directly into electricity through the photovoltaic effect. They come in various types, such as monocrystalline, polycrystalline, and thin-film solar cells. While monocrystalline cells generally offer higher efficiency, polycrystalline cells are more cost-effective and easier for DIY projects.

In addition to solar cells, a soldering iron is essential for connecting the cells. You will also need solder, which is a metal alloy that melts to join electrical components. Strong and durable wiring, preferably of a gauge suitable for your panel’s output, will ensure efficient energy transfer. Other tools required for assembly may include a multi-meter for measuring voltage, a frame to hold the solar cells, and encapsulating materials like clear plastic or glass to protect your panel from the environment.

2. UNDERSTANDING SOLAR CELLS

Delving into the core function of solar cells is vital for assembling a mini solar panel. Solar cells operate on the principle of the photovoltaic effect, where photons from sunlight knock electrons loose in a semiconductor material, generating an electric current. Understanding this principle can help in realizing why the arrangement and type of solar cells chosen are important. They are usually composed of silicon, which is doped to create a p-n junction that facilitates electron flow when exposed to light.

Another aspect to consider is the efficiency rating of solar cells. This rating will determine how much sunlight can be converted into electricity. Higher efficiency cells will produce more energy in a given space, making them an attractive option for mini solar panels where space may be limited. Factors like temperature and the angle of sunlight also affect efficiency. These parameters will guide the layout for your final assembly.

3. DESIGNING THE LAYOUT

Organizing your solar cells into a coherent layout is another critical phase in assembling your panel. This involves deciding on a series or parallel configuration. A series connection can increase voltage, while a parallel link boosts current. Each of these options has its benefits, dictated by the intended application of the solar panel. For standard applications like charging batteries, a hybrid approach that utilizes both configurations might yield the best results.

Creating an efficient layout can be facilitated by drafting a blueprint or using software that simulates electrical circuits. This planning phase can save considerable time in the long run and ensure that the final assembly is simplified. Once the design is finalized, proceed to arrange the cells as planned, maintaining consistent spacing to ensure that each cell can capture maximum sunlight without interference from neighboring cells.

4. SOLDERING AND ELECTRICAL CONNECTIONS

One of the most delicate stages in the assembly process involves soldering. The solder joints must be strong and reliable, as these connections will carry the electric current generated by the solar cells. Ensure that the temperature of the soldering iron is optimal to avoid damaging the cells while achieving a clean bond. It’s advisable to work on a heat-resistant surface and use safety precautions, including protective eyewear, as soldering can produce fumes.

When soldering, it is crucial to follow the layout designed in the previous step. Connect the positive terminal of one cell to the negative terminal of the adjacent cell, repeating this sequence for all cells in series. If your design incorporates a parallel connection, make sure to connect similar terminals. After completing the soldering, inspect all connections for stability before moving on to the next phase of assembly, as any errors at this stage can lead to inefficiencies or failures in your solar panel.

5. ASSEMBLING THE FRAME

Once electrical connections are securely completed, the next task is to construct a frame for the solar panel. This frame is essential as it provides physical protection for the solar cells and supports them against environmental factors like wind and rain. Materials commonly used for frames include wood for a DIY approach or aluminum for enhanced durability and lightweight properties.

The frame should be constructed to precisely fit the layout of the solar cells, leaving enough space for potential expansions or additional components. Ensure that the frame elevates the solar cells to allow for drainage when it rains. Additionally, use waterproof sealants, particularly if your region experiences harsh weather conditions. A well-constructed frame will significantly enhance the lifespan and performance of the mini solar panel.

6. ENCLOSED DESIGN AND PROTECTION

After structural assembly, the panel must be well protected from the elements. Encapsulation is a process that involves sealing the solar cells within a protective layer, preventing moisture, dust, and physical impact from harming the cells. High-quality encapsulation materials are available, such as EVA (ethylene-vinyl acetate) and tempered glass, which not only provide protection but also allow sunlight to penetrate efficiently.

The encapsulating layer should be clear to maximize light absorption while being robust enough to withstand external pressures. Once the solar cells are secured and the protective layer is applied, your mini solar panel will be much more resilient. This final step is crucial in ensuring the longevity of the panel and the consistent performance over time.

7. TESTING OUTPUT AND EFFICIENCY

Upon assembly completion, conducting thorough testing is imperative to assess the functionality of the mini solar panel. A multi-meter can be utilized to measure the voltage and current output, ensuring that the assembled panel meets expected specifications. If the output does not align with predictions, it will be necessary to troubleshoot potential issues, such as faulty connections or inadequate light exposure.

Adjustments may include repositioning the panel to ensure optimal sunlight exposure or checking the integrity of the solder joints. Comprehensive testing of both voltage and current in various lighting conditions can provide insights into the efficiency of each solar cell within the panel and validate your assembly’s effectiveness.

8. INSTALLATION PROCESS

Once verification of the panel’s functionality is complete, determine the optimal location for installation. Factors such as sunlight exposure, shading from nearby objects, and ease of access for maintenance should be emphasized. Ideally, the panel should be mounted at an angle to maximize sunlight capture throughout the year. Various installation options include rooftop mounting, pole mounting, or ground mounting, depending on the type of application intended for the solar panel.

Secure the panel using mounting brackets or straps that can withstand wind and weather conditions. Ensure that the electrical connections to batteries or any other devices are made in accordance with safety standards to prevent short circuits or overloads. After successful installation, monitor the performance regularly to guarantee that the system operates efficiently.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE BENEFITS OF A MINI SOLAR PANEL?

Mini solar panels offer various advantages, making them an appealing choice for individual users and households. 1. Cost-Effectiveness: These smaller systems often represent a more affordable entry point into solar energy, allowing users to familiarize themselves with solar technology without significant financial commitment. 2. Portability: Lightweight and compact, they can be easily transported for various applications, such as camping or emergency power. 3. Eco-Friendly Solution: Using solar energy reduces dependence on fossil fuels, contributing positively to the environment by lowering carbon footprints.

Overall, mini solar panels not only signify energy independence but also foster sustainability. Despite their size, they can effectively contribute to energy needs and promote awareness about renewable sources. Their integration into daily life can inspire a greater commitment to more extensive solar installations in the future.

HOW LONG DOES IT TAKE TO ASSEMBLE A MINI SOLAR PANEL?

The duration required to assemble a mini solar panel largely depends on the complexity of the design and the individual’s experience with similar projects. For someone familiar with working with electrical components, assembling a basic panel might take approximately 4 to 8 hours. This includes sourcing materials, following tedious processes like soldering, and constructing the protective frame.

For beginners, additional time may be necessary to understand the intricacies of solar technology and gain comfort with the tools. Comprehensive research prior to assembly can also contribute to a more efficient construction process. Allocate sufficient time for testing and troubleshooting after construction, ensuring optimal performance before usage.

ARE THERE ANY REGULATIONS FOR INSTALLING SOLAR PANELS?

Yes, regulatory considerations are crucial when installing solar panels, even mini systems. Local building codes, zoning laws, and safety standards play a significant role in the installation process. It is essential to check whether there are specific guidelines regarding solar panel installations in your area, as certain regions may require permits or inspections during and after installation.

Moreover, ensuring compliance with electrical codes can prevent potential hazards and uphold safety standards. Familiarizing oneself with these regulations protects the investment and aids in integrating the solar panel into existing energy systems seamlessly. Always consult with local authorities or professional service providers before proceeding with installation to avoid costly errors.

In summary, assembling a mini solar panel is a multi-step process that combines selection and arrangement of solar cells, careful soldering for electrical connections, and robust framing for protection. It warrants attention to detail, a comprehensive understanding of the components involved, and consideration for the specific use cases intended for the generated energy. This undertaking not only empowers the individual to produce their own renewable energy but also fosters a deeper appreciation for sustainable technologies. Choose the right materials, follow the outlined procedures, and perform thorough tests to ensure a functional and efficient solar panel. The empowerment resulting from this endeavor can spark an interest in larger, more complex solar projects, ultimately contributing to a greater movement towards renewable energy adoption. With proper planning and execution, the assembly of a mini solar panel can lead to long-term benefits, paving the way for broader sustainability efforts.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-assemble-a-mini-solar-panel/