Assembling a 7-in-1 solar car involves several key steps that showcase the integration of renewable energy, engineering design, and practical application. The process can be broken down into the following essential aspects: 1. Understanding components, 2. Mastering assembly techniques, 3. Implementing guidance on solar power setup, 4. Ensuring troubleshooting measures. Furthermore, the intricate details regarding the role of each component in relation to solar energy conversion warrant thorough examination and comprehension. This allows for an informed assembly that not only emphasizes functionality but also enhances the experience of engaging with sustainable energy technology.

1. UNDERSTANDING COMPONENTS

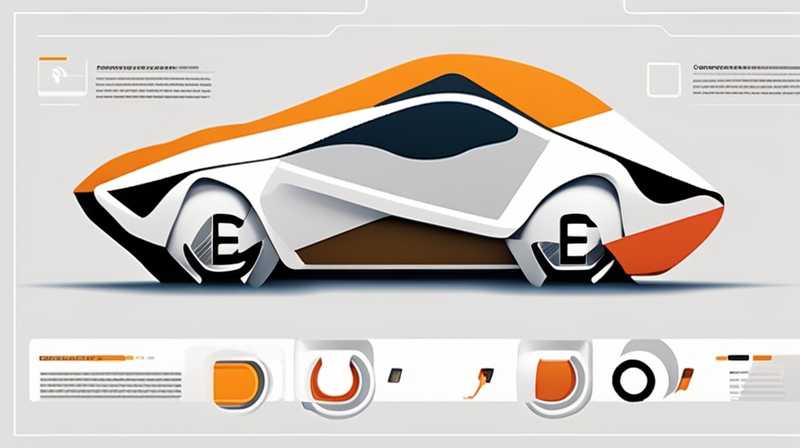

To embark on the journey of assembling a 7-in-1 solar car, one must possess a foundational knowledge of the various components involved in the project. These components typically include a solar panel, a motor, wheels, gears, a chassis, and various connectors and converters. Understanding the function of each part is essential to ensure a smooth assembly process and optimal performance.

The solar panel serves as the foremost component that harnesses solar energy. It does this by converting sunlight into electrical energy through the photovoltaic effect. The efficiency of the solar panel is pivotal since it directly influences how much energy the vehicle can generate. A higher-efficiency panel means more energy production, which is crucial for powering the motor and sustaining the overall functionality of the car. The motor, on the other hand, translates the electrical energy into mechanical energy, propelling the moving parts of the car.

Moreover, the chassis provides the structural framework for the vehicle. It must be sturdy yet lightweight; this balance is essential for locomotion and is determined by the materials used, which often include plastics or lightweight metals. The wheels and gears ensure smooth movement and can affect the speed and maneuverability of the solar car. Gears may vary in size and configuration, which can result in different driving experiences. Lastly, the connectors and converters are vital for creating a functional circuit that allows energy to flow from the solar panel to the motor effectively.

2. MASTERING ASSEMBLY TECHNIQUES

The assembly techniques employed during the construction of the solar vehicle play a significant role in determining its performance. Each step in the assembly must be executed meticulously to ensure a cohesive structure. Initially, one must lay out all components in a systematic manner to prepare for a seamless assembly experience.

Starting with the chassis, securing the solar panel to the top of the chassis is crucial, as it will be the primary source of energy. Ensure that the connections are tight and that the panel is angled to receive maximum sunlight exposure when the vehicle is in operation. The orientation of the panel may significantly enhance or compromise energy production, thereby affecting performance.

Following this, the placement of the motor is equally paramount. It must be positioned in such a way that allows for optimal distribution of power received from the solar panel. Additionally, connecting the motor to the wheels through the gears requires precision; misalignment can lead to inefficiencies in movement or even damage the components. Each gear’s ratio can determine the speed capacity of the vehicle, thus experimenting with various configurations can yield valuable insights into performance optimization.

Wiring connections must be handled with care; ensure that the positive and negative connections are accurately aligned to prevent short-circuits or malfunctioning. Implementing correct soldering techniques, when applicable, can provide a durable connection that withstands movement and vibrations. Testing the connections frequently throughout the assembly process is recommended, as this can help identify issues before they escalate into significant problems.

3. IMPLEMENTING GUIDANCE ON SOLAR POWER SETUP

Once the physical assembly of the solar vehicle is underway, shifting focus towards the effective setup of the solar power system is imperative. The setup encompasses not only the solar panel but also the associated electrical circuitry that governs how energy is managed and utilized.

The placement of solar panels should be oriented towards the most sun-exposed side, optimizing the sunlight capture during operation. The angle of the solar panel can be adjusted according to the geographic location and season; this can significantly impact the energy output. Utilizing lightweight, flexible solar panels can enhance design adaptability, allowing the vehicle to maintain an aerodynamic profile while harnessing solar energy efficiently.

Understanding the need for a charge controller is critical; this device regulates the voltage and current coming from the solar panel to the motor. Without a charge controller, the components could be exposed to voltage spikes that may damage sensitive electronic parts. This becomes particularly vital during peak sunlight hours when energy generation is at its maximum.

Moreover, it is crucial to ensure that the energy management system implemented allows for efficient power distribution throughout the system. Incorporating energy storage systems, like batteries, can store excess energy generated and provide a supplemental power source when conditions are less than ideal, such as during overcast weather. This dual approach can improve the reliability of solar energy usage in the car.

4. ENSURING TROUBLESHOOTING MEASURES

Finally, preparation for troubleshooting measures cannot be overlooked when assembling a solar car. Various factors may impede the optimal functioning of the car, necessitating a proactive approach to problem-solving. Issues can range from inadequate power generation to mechanical failures in the assembly.

When performance seems subpar, one should commence with diagnosing the solar panel. Observing the panel’s exposure to the sun is essential; any shading can greatly diminish its efficacy. Additionally, examining connections for corrosion or loose wiring is crucial, as these can disrupt the flow of power. A multimeter can be employed to test if the panel is generating the expected voltage and current under sunlight.

Moreover, if the motor fails to respond, checking the charge controller for malfunction or incorrect settings is advisable. Misconfigured solar controllers may prevent energy distribution from reaching the motor, impairing movement. Conducting routine checks can help preemptively identify issues before they manifest into larger problems, ultimately ensuring that the vehicle operates as intended.

By implementing a thorough understanding of the assembly process alongside effective solar power management and troubleshooting, one can successfully complete the assembly of a 7-in-1 solar vehicle, leading to an enriching experience with renewable energy.

WHAT ARE THE MAIN COMPONENTS OF A 7-IN-1 SOLAR CAR?

The principal components of a 7-in-1 solar car typically include a solar panel, a motor, wheels, gears, a chassis, connectors, and possibly batteries for energy storage. Each part plays a significant role in the car’s overall function and efficiency. The solar panel acts as the primary energy source by converting sunlight into electrical energy, while the motor utilizes this energy to propel the vehicle. Wheels and gears influence speed and maneuverability, contributing to the car’s overall drive performance. The chassis serves as the foundational structure, while connectors facilitate the necessary electrical pathways within the system.

HOW CAN TROUBLESHOOTING BE EFFECTIVE FOR SOLAR CARS?

Effective troubleshooting entails systematically diagnosing issues that may arise during the operation of a solar car. One should first observe the behavior of the solar panel to ensure it is receiving adequate sunlight, as shading can dramatically reduce performance. Verifying all electrical connections, checking for corroded or loose wires, and using tools like multimeters can identify faults in the electrical system. When problems with the motor occur, inspecting the charge controller for proper setup can reveal configuration errors that might prevent effective energy transfer. Early detection and systematic troubleshooting allow for prompt resolution, ensuring the solar car operates efficiently.

HOW DOES SOLAR ENERGY POWER A 7-IN-1 SOLAR CAR?

Solar energy powers a 7-in-1 solar car through a straightforward conversion process. Solar panels with photovoltaic cells capture sunlight and convert it into electrical energy. This energy is then routed through a charge controller to prevent overcharging and subsequently delivered to the motor, which converts the electrical energy into mechanical energy. The efficient design of the solar car ensures that energy flows smoothly from the panel to the motor while also allowing for storage in batteries, if employed, for later use. A well-designed solar car leverages renewable energy effectively, demonstrating sustainable engineering principles.

Emphasizing the assembly of a 7-in-1 solar car reveals the intersection of engineering, renewable energy technology, and hands-on learning. Crafting such a car not only provides insight into solar energy’s practical applications but also cultivates problem-solving skills and a deeper appreciation for sustainable practices. Engaging with this project enriches the understanding of mechanical and electrical systems while fostering creativity in design and functionality. Each component’s contribution is immensely valuable, from the solar panel capturing sunlight to the gear ratios affecting speed and maneuverability. Ensuring that every action during assembly is meticulous leads to satisfactory outcomes, ultimately making the assembly process a rewarding endeavor.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-assemble-a-7-in-1-solar-car/