To adjust the solenoid valve of a solar energy system effectively, one should focus on these key aspects: 1. Understand the purpose of the solenoid valve, 2. Identify the specific model and configuration, 3. Gather the necessary tools, 4. Follow a systematic adjustment procedure. The solenoid valve plays a critical role in regulating the flow of fluids in solar energy applications, whether it is for heating water panels or maintaining circulation in solar thermal systems. Understanding its function and how it interacts with other components is vital to ensure optimal performance. For successful adjustment, one must consider factors such as pressure settings, voltage specifications, and the architecture of the solar energy setup being utilized. Each of these points will be elaborated upon for clarity and effective adjustment.

1. UNDERSTANDING THE FUNCTION OF THE SOLENOID VALVE

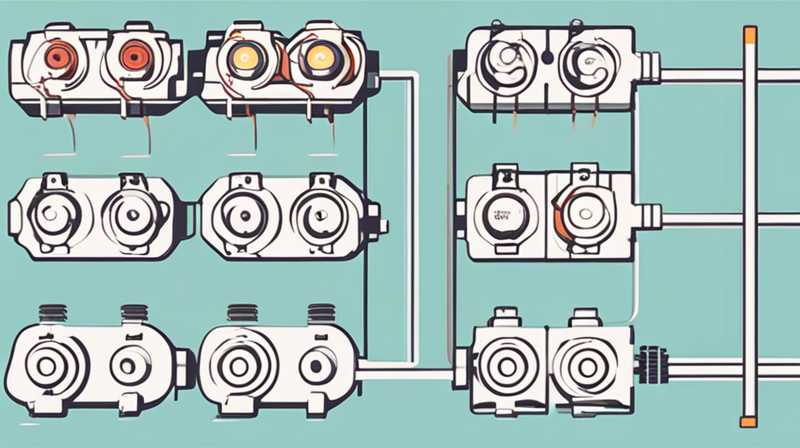

A solenoid valve is a crucial element in various solar energy systems, especially those using liquid heat transfer mediums. Its primary role is to control the passage of fluid based on electrical signals, ensuring that heat transfer processes occur efficiently. By controlling the flow, it consequently impacts system performance, energy efficiency, and overall effectiveness of the solar heating or cooling process.

Exploring how a solenoid valve operates involves delving into its electrical components and mechanical parts. When an electric current passes through the solenoid coil, it generates a magnetic field that actuates a plunger. This plunger either opens or closes the valve, attuning the flow of the working fluid accordingly. Consequently, understanding this actuation mechanism aids technicians in diagnosing problems and determining the necessary adjustments.

In addition, comprehending the system’s layout, including its pipes, pumps, and controllers, is paramount for effective troubleshooting and maintenance. Each solar installation might have varying requirements based on its configuration, as some may use direct circulation, while others are more indirect in nature. Therefore, recognizing the system type aids in effective operation and adjustment of the solenoid valve.

2. IDENTIFYING THE SOLENOID VALVE MODEL

Different solar energy systems employ various solenoid valve models tailored to their specific applications. Understanding the features of the solenoid valve in use is essential for proper adjustment and maintenance. Every model may have distinct technical specifications, including voltage ratings, flow rates, response times, and operating pressures.

The first step in identifying the appropriate solenoid valve involves examining its manufacturer markings, specifications, and model numbers. This information generally resides on a label affixed directly to the valve. Additionally, owner’s manuals or technical documentation accompanying the solar energy unit will provide the necessary information concerning the valve’s characteristics. Once identified, technicians will be able to access relevant technical resources such as installation guides, maintenance manuals, and manufacturer support for that specific model.

Moreover, knowing whether the valve functions as normally closed or normally open is vital. This understanding defines how fluid flow is managed under various conditions. For example, a normally closed valve will only open when energized, while its counterpart remains open in an unenergized state. Such knowledge impacts the design of the control system and the user’s interaction with the solar energy system overall.

3. GATHERING NECESSARY TOOLS FOR ADJUSTMENT

Before embarking on the adjustment process, it is prudent to gather all necessary tools and materials. The right tools don’t just expedite work but also enhance safety and reduce the likelihood of making errors. Common tools might include screwdrivers, wrenches, pliers, multimeters, and a pressure gauge, depending on the nature of the adjustment.

A thorough inspection of the solenoid valve area should also be conducted to ensure ease of access, which may require additional materials to secure the environment or organize the workspace. A clean area devoid of any obstructions reduces risks and allows for a focused effort on the task at hand.

Additionally, verifying that the power supply is disconnected before commencing work is critical, as it prevents accidental activation of the valve during adjustment. It is advisable to have electrical safety gear on hand, such as insulated gloves and goggles, to safeguard against potential accidents.

4. PROCEDURE FOR ADJUSTMENT OF THE SOLENOID VALVE

With a deep understanding of the solenoid valve’s function, the specific model, and a well-prepared toolkit, attention turns to the adjustment methodology. This systematic approach ensures that adjustments lead to optimal performance, minimal leakage, and maximized system efficiency.

Initially, inspect the valve for any visible signs of wear, corrosion, or damage. Such issues can contribute to malfunctioning and may require replacement rather than adjustment. Following this, reconnect the power supply cautiously while monitoring the solenoid’s operation. Observe whether the valve opens and closes appropriately in response to electric signals. If discrepancies are noted, it may be necessary to adjust the coil power or check the connections.

For valves with adjustable pressure settings, refer to manufacturer specifications to determine the desired pressure range. Utilize a pressure gauge to monitor fluid pressure while making adjustments to the valve. This step necessitates sharp attention, as improper pressure can lead to inefficient operation or even damage.

Moreover, establishing a testing regimen post-adjustment is essential. After adjustments are made, reconnect all power sources and initiate the solar energy system. Monitor the solenoid valve’s operation under typical load conditions, verifying that it performs as expected without leaks or unusual noises. Periodic checks after making adjustments help confirm reliability and allow for the early detection of any future operational issues.

5. TROUBLESHOOTING COMMON ISSUES WITH SOLENOID VALVES

Despite proper adjustments, malfunctions might still occur in solenoid valves. Common issues can range from improper actuation to complete failure of the valve. Understanding these issues and how to tackle them is crucial for maintaining the longevity of the solar energy system.

One prevalent problem is electromagnetic interference, which can cause erratic valve performance. Ensuring that the wiring is properly shielded and distanced from sources of interference may resolve this issue. Regular inspections of electrical connections are also necessary, as loose connections could lead to inconsistent power supply and intermittent operation of the valve.

Another concern is sediment buildup within the valve. This can restrict flow and reduce efficiency. Routine cleaning or replacement of the valve is a proactive way to mitigate such issues. Implementing a filtration system might also help in preventing such problems in the initial stages of operation.

FREQUENTLY ASKED QUESTIONS

WHAT SIGNS INDICATE A FAULTY SOLENOID VALVE IN A SOLAR ENERGY SYSTEM?

Indications of a malfunctioning solenoid valve may vary, but several common symptoms tend to surface. 1. Failure to open or close completely, which compromises fluid regulation, causing either overpressure or underpressure in the system. 2. Unusual sounds, such as rattling or hissing, that suggest internal damage or blockages may also be observed. 3. Leakage around the valve body indicates wear or improper sealing, which leads to inefficiency and energy loss. 4. If the valve does not respond to control signals, it signifies electrical issues, possibly related to wiring or the solenoid itself. Moreover, when in doubt, calling a professional for diagnosis is prudent.

HOW DOES ONE MAINTAIN A SOLENOID VALVE TO ENSURE LONGEVITY?

To extend the operational life and efficiency of a solenoid valve, regular maintenance is essential. Firstly, establishing a routine checking schedule, including visual inspections for signs of wear, is crucial. This includes examining for corrosion, rust, or any physical damage to the valve and its connections. Secondly, periodic cleaning of the valve and surrounding area prevents sediment buildup that can impair function. Employing a filtration system to clear contaminants prior to entering the valve is another significant preventive measure. Lastly, ensuring that the wiring and electrical components are secure and free from damage maintains proper mechanical actuation. Consulting the manufacturer’s guidelines for specific maintenance schedules and procedures will further enhance the life span of the solenoid valve.

CAN A SOLENOID VALVE BE REPAIRED, OR DOES IT NEED REPLACEMENT?

Whether a solenoid valve can be repaired or requires replacement depends on the nature and extent of the issues it faces. If minor issues, such as electrical connection failures or blockage due to sediment, are diagnosed, then repair is often possible. Simple actions such as cleaning or re-terminating electrical connections can restore proper functionality. In contrast, serious mechanical issues, substantial corrosion, or internal component damage may necessitate a complete replacement of the valve for optimal system performance. Ultimately, evaluating the cost-effectiveness of repairs versus replacements is key. When in doubt, consulting a specialist ensures the best decision for maintaining the solar energy system’s efficacy.

Ensuring the correct adjustment of the solenoid valve in solar energy systems is vital for both operational efficiency and the longevity of the entire setup. Proper comprehension of its function, identifying the right model, assembling necessary tools, and executing an organized adjustment process comprise fundamental steps toward achieving an effective solution. With the potential for common issues also addressed, maintaining functionality becomes feasible. Ongoing vigilance and preventive measures, including regular maintenance checks and the prompt addressing of any operational anomalies, foster the sustainability and reliability of these systems. Ultimately, the deployment of correctly adjusted solenoid valves not only enhances energy output but also minimizes operational costs, thereby aligning with the broader goals of energy efficiency and environmental sustainability. Consistent upholding of knowledge, skills, and techniques related to solenoid valves can substantially contribute to the effectiveness of solar energy solutions, paving the way towards a greener future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-adjust-the-solenoid-valve-of-solar-energy/