1. Identify the purpose of the solar injection tube, 2. Gather necessary tools and materials, 3. Safely drain existing fluid, 4. Introduce the liquid into the tube.

The method for adding liquid to the bottom of a solar injection tube involves several precise steps to ensure functionality and efficiency. First, recognize the purpose of the solar injection tube in your system; it plays a crucial role in transferring heat or fluid from solar collectors to a storage system. Second, gather essential tools, which may include a funnel, appropriate liquid, and safety gear to manage the process responsibly. Third, ensure existing fluid is drained safely to prevent overflow or contamination when adding new liquid. Finally, using a funnel or liquid pump, introduce the required liquid into the bottom of the injection tube gradually to maintain optimal performance. This procedure is instrumental in maintaining the efficiency of solar heating systems and ensuring long-term functionality.

1. UNDERSTANDING THE SOLAR INJECTION TUBE

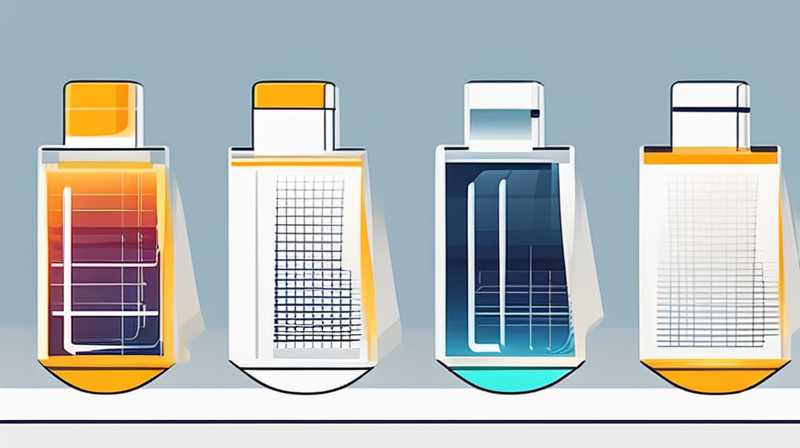

Solar energy harnesses sunlight and converts it into usable heat. Central to this system is the solar injection tube, which is instrumental in transferring heated fluid from collectors to the storage area and subsequently to your intended application. This component exists in various setups, whether for residential heating, swimming pools, or industrial applications. Understanding the purpose and operational mechanics of this tube is paramount when considering maintenance tasks, such as adding liquid.

The design of the solar injection tube is often influenced by the material it is made from, including metal or durable plastic. The choice of material affects not only the thermal efficiency but also the longevity of the tube itself. Regular monitoring and maintenance can prevent a host of problems associated with fluid transport, including blockage, air bubbles, or leaks. Recognizing when to add liquid and how to do so correctly ensures that your solar heating system operates at peak efficiency, providing a reliable energy source.

2. GATHERING NECESSARY TOOLS AND MATERIALS

Before embarking on the endeavor of adding liquid to the solar injection tube, gathering the necessary tools and materials is essential. The specific equipment required often includes a funnel, suitable liquid, a wrench for any fittings, a bucket for drainage, and personal protective equipment (PPE) to ensure safety during the procedure. Using the right tools not only streamlines the process but also reduces the likelihood of mishaps that may compromise the solar heating system’s integrity.

The liquid used in the solar injection tube varies based on the system design. Often, propylene glycol or another antifreeze liquid is used to protect systems from freezing while ensuring efficient heat transfer. Understanding the proper liquid composition is crucial for your system’s longevity and performance. Likewise, having all required materials readily available prior to commencing the process fosters an efficient and safe operation, allowing the task to be completed methodically without unnecessary interruptions.

3. SAFELY DRAINING EXISTING FLUID

Prior to introducing new liquid into the injection tube, accomplishing the safe drainage of the existing fluid becomes a priority. Begin by turning off the solar heating system to prevent unexpected spills or accidents. Identifying the drain valves or outlets is essential in this step, as it allows for a controlled release of the fluid within the system. Carefully place a bucket or reservoir under these fittings to catch the draining liquid as it flows out.

Monitoring the drainage process is crucial to prevent overflows. Depending on the system’s scale, this fluid may be hot, requiring adequate cooling time before handling. Additionally, it is important to properly dispose of or recycle the drained liquid according to local regulations, especially if it contains chemicals. Following these steps ensures a clean work environment and lays a solid foundation for the subsequent addition of fresh liquid into the solar injection tube.

4. INTRODUCING THE LIQUID INTO THE TUBE

The introduction of liquid into the solar injection tube represents the final significant phase in this process. Begin by preparing your funnel or liquid pump, ensuring that it is clean and free from contaminants. This aspect is critical because any impurities can potentially affect the efficiency and function of the solar heating system. Place the funnel securely into the top opening of the injection tube or use the pump to carefully transfer the new liquid.

When adding the liquid, monitor it closely. Gradually introducing the liquid helps prevent the formation of air pockets, which could disrupt fluid flow throughout the system. Should any air be trapped in the tube, it may lead to inadequate heating performance. After completing the addition, securely close any access points, check for leaks, and conduct a system test to ensure that everything operates correctly.

5. MAINTAINING SYSTEM INTEGRITY AFTER ADDITION

Once the new liquid has been introduced and the system is functioning correctly, maintaining its integrity is imperative. Regular inspections ensure that components, including the solar injection tube, remain in good condition and prevent potential issues from arising. Establishing a maintenance schedule allows for timely interventions, preserving the efficiency and longevity of the overall solar heating system.

Monitoring for any changes in system performance is also crucial. Changes may indicate that further adjustments, such as additional liquid, might be necessary. Being vigilant about these aspects helps maintain a seamless operation, safeguarding your investment in solar technology. Engagement in proactive maintenance practices equips individuals with the knowledge and resources to manage their solar heating systems effectively against wear and tear.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLAR INJECTION TUBE?

A solar injection tube is a vital component in a solar heating system designed to transfer heated fluid from solar collectors to storage elements such as tanks or directly to the point of use. The functionality of this tube significantly affects the overall efficiency of the heating system. Typically constructed from heat-resistant materials, these tubes ensure that the heated fluid reaches its destination while minimizing thermal loss. Regular maintenance, such as checking for leaks or blockages, is necessary to keep the system operating effectively. An adequately maintained injection tube maximizes the benefits of solar energy, reducing reliance on conventional power sources and promoting sustainable practices.

HOW OFTEN SHOULD I CHECK MY SOLAR INJECTION TUBE?

Regular inspections of your solar injection tube are essential for maintaining the efficient operation of your solar heating system. It is advisable to conduct these checks at least twice a year, preferably before and after the heating season, to ensure everything is functioning correctly. Look for signs of wear, leaks, or blockages that may inhibit performance. Additionally, monitoring fluid levels and replenishing as necessary helps prevent overheating or freezing issues. Understanding the specific demands of your system based on its location or application can also dictate the frequency of these inspections. By remaining attentive to the condition of the injection tube, users can optimize performance, mitigate potential issues, and extend the lifespan of their solar heating systems.

CAN I USE ANY TYPE OF LIQUID IN THE INJECTION TUBE?

Not all liquids are suitable for use in the solar injection tube, and selecting the appropriate fluid is crucial for optimal performance and protection of the system. Common liquids used in solar heating systems include propylene glycol, ethylene glycol, or specially formulated antifreeze solutions that prevent freezing and improve thermal transfer. When choosing a liquid, it is essential to consider factors such as compatibility with the system materials, freezing point, and thermal efficiency. Using inappropriate fluids can lead to corrosion, lower efficiency, and ultimately shorten the lifespan of the solar injection tube and associated components. Therefore, adhering to manufacturer guidelines or consulting with a professional regarding fluid selection ensures that your system operates smoothly year-round.

The importance of adding liquid to the bottom of the solar injection tube cannot be overstated. Properly maintaining fluid levels is essential for optimizing heat transfer efficiency and ensuring that the solar heating system functions effectively. Failure to follow the correct procedure when adding liquid risks damaging components, creating leaks, or resulting in reduced overall performance. Regularly implementing best practices for fluid management not only extends the lifespan of the solar system but also enhances energy efficiency, leading to significant cost savings over time. By engaging in proactive maintenance and addressing any issues promptly, individuals can take full advantage of the benefits that solar energy offers. Embracing sustainability through renewable energy sources, such as solar heating systems, contributes to a cleaner environment and promotes a sustainable future. Each step taken in maintaining these systems plays a crucial role in leveraging solar technology to its fullest potential, aligning with modern efforts focused on energy independence and eco-conscious living.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-add-liquid-to-the-bottom-of-the-solar-injection-tube/