Hydraulic oil is essential for the optimal functionality of various solar energy systems, particularly those involving hydraulic mechanisms such as tracking systems and solar concentrators. 1. To add hydraulic oil, one must identify the specific reservoir designed for hydraulic fluid. 2. Next, ensure the system is turned off and depressurized to avoid accidents or leaks during the filling process. 3. Using the appropriate type of hydraulic oil, fill the reservoir to the indicated level, checking for any leaks post-filling. 4. Regular maintenance and timely topping up of hydraulic oil help in prolonging the life of hydraulic components and ensures efficient operation of the solar energy system.

1. UNDERSTANDING HYDRAULIC SYSTEMS IN SOLAR ENERGY

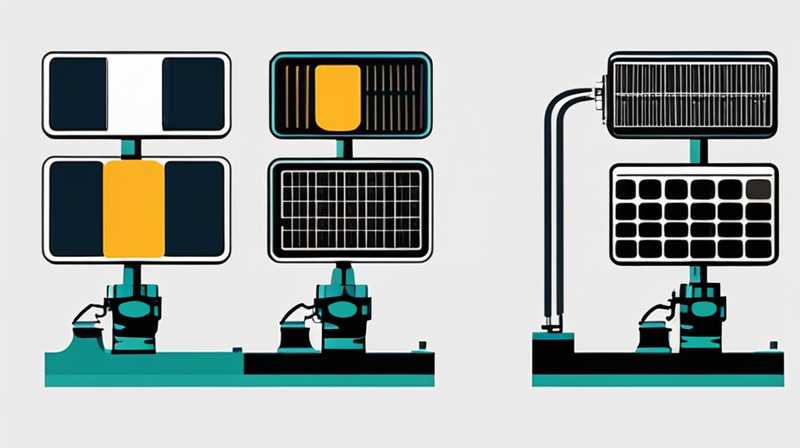

Hydraulic systems play a critical role in enhancing the efficiency of solar energy applications. These systems rely on the transmission of power through liquid, enabling movement and control of mechanisms used in solar tracking and concentrating setups. Hydraulic energy is particularly beneficial for solar installations that require precision alignment to capture maximum sunlight, thereby improving energy yield.

Hydraulic fluid serves as the life force of these systems. Its primary functions include transmitting power, lubricating moving parts, and transferring heat away from components to maintain optimal operating temperatures. Given that the effectiveness of hydraulic systems directly influences the performance of solar installations, understanding how to properly manage hydraulic fluid is essential for optimal operation.

2. IDENTIFYING THE CORRECT HYDRAULIC OIL

Choosing the right hydraulic oil is crucial for the longevity and functionality of solar energy systems. Various types of hydraulic oils exist, each designed for specific operational requirements and environmental conditions. The selection process should focus on aspects such as viscosity, temperature range, and compatibility with system materials.

Viscosity measures how easily a fluid flows; for instance, thick oils may be ineffective in cold conditions but necessary at high temperatures. Additionally, some systems may require biodegradable oils, which can mitigate environmental impacts. Researching manufacturers’ recommendations is vital for ensuring optimal performance and avoiding potential issues due to oil incompatibility with system components.

3. PREPARING THE SYSTEM FOR OIL ADDITION

Before proceeding to add hydraulic fluid, it is critical to prepare the solar energy system. The first step involves shutting down the equipment and allowing it to cool. This phase is essential for both safety and ensuring accurate reading of oil levels in the system. Pressure relief valves must be actuated to remove any stored energy and ensure a safer working environment, minimizing the risk of unexpected fluid ejection during the process.

Once the system is depressurized, locate the hydraulic fluid reservoir. Many systems feature a fill cap marked for easy identification. Prior to removal, check for any external damage or leaks around the area to avoid contaminating the hydraulic fluid. Proper preparation ensures that the subsequent filling process is smooth and free of complications.

4. FILLING THE HYDRAULIC OIL RESERVOIR

After preparing the system and ensuring safety, the next step involves carefully adding the hydraulic oil. Selecting a quality funnel helps prevent spillage and allows for a controlled flow into the reservoir. It is essential to pour the hydraulic oil slowly, monitoring the fill level closely to avoid overfilling, which may lead to pressure build-up or overflow.

The reservoir often features marking lines indicating the appropriate fill levels. Checking these levels at multiple intervals during the filling process can prevent inaccuracies. Once the filling process is complete, secure the fill cap tightly to ensure no contaminants enter the system.

5. MONITORING AND MAINTAINING HYDRAULIC OIL LEVELS

Regular monitoring of hydraulic oil levels is vital for sustaining the operational efficiency of solar energy systems. It is advised to establish a routine maintenance schedule where hydraulic fluid levels and condition are assessed periodically. During these checks, inspect for fluid contamination, discoloration, or unusual odors that indicate degradation.

Additionally, visual inspections for leaks in the hydraulic system can significantly reduce the risk of severe mechanical issues. A well-maintained hydraulic system not only optimizes the performance of solar energy applications but also extends the lifecycle of components, translating into cost savings and operational efficiency.

6. HANDLING HYDRAULIC OIL SAFELY

Working with hydraulic oil necessitates adherence to safety protocols to prevent accidents and exposure to harmful substances. Begin by using appropriate personal protective equipment (PPE) such as gloves and safety glasses. In the case of spills, keep absorbent materials handy and familiarize yourself with emergency response procedures for hazardous materials.

Proper disposal of used hydraulic oil is also imperative. Many regions have regulations governing the disposal of such fluids. Engaging with certified waste disposal professionals ensures that old oils are removed safely and in compliance with environmental guidelines. Awareness and adherence to these safety measures safeguard personnel and minimize ecological footprints.

7. COMMON ISSUES WITH HYDRAULIC SYSTEMS IN SOLAR ENERGY

Despite diligent maintenance, challenges can arise within hydraulic systems integrated into solar energy applications. Common issues include leaks, fluid contamination, and component wear. A leak can lead to decreased performance or complete system failure, necessitating immediate repair. Contaminated oil poses a risk to components, often resulting in increased friction and overheating.

Proper diagnostic practices can aid in identifying these issues early on. Utilizing fluid analysis techniques may help detect contamination, allowing for timely intervention. Understanding these challenges can mitigate downtime and maintain smooth operation, thereby ensuring efficiency in solar energy systems.

8. ADVANTAGES OF USING HYDRAULIC SYSTEMS IN SOLAR APPLICATIONS

Hydraulic systems offer numerous advantages in the realm of solar energy, primarily due to their efficiency and power density. These systems can provide significant mechanical force with comparatively smaller machinery, thereby saving space and reducing the overall weight of installations. Furthermore, hydraulic components typically exhibit superior reliability and adaptability compared to mechanical counterparts, allowing for more versatile applications.

In addition, hydraulic systems often result in smoother and more precise movements, such as those required for solar tracking. By maintaining optimal orientation relative to the sun, these systems significantly enhance energy capture during peak sunlight hours. This not only maximizes the efficiency of solar arrays but can also yield greater economic returns for users.

9. REGULATIONS AND STANDARDS FOR HYDRAULIC OIL USAGE

Various regulations and standards inform the usage of hydraulic oil in solar energy systems. These may include safety guidelines pertaining to the handling and disposal of hydraulic fluids alongside environmental regulations to mitigate pollution risks. Understanding these regulations ensures that enterprises comply with local and international standards, thereby reducing potential legal liabilities.

Furthermore, certification by recognized industry bodies often guarantees that hydraulic oils meet specific performance criteria that align with sustainability goals. Selecting oils that comply with such standards can enhance the green credentials of solar energy projects, thereby attracting environmentally conscious investors and customers.

10. CONSIDERATIONS FOR FUTURE DEVELOPMENTS

The future of hydraulic systems in solar energy is poised for innovation. Advances in fluid technology and materials science may lead to the development of biodegradable hydraulic oils, enhancing the environmental footprint of solar applications. Furthermore, ongoing innovations may refine hydraulic system designs, improving compactness and operational efficiencies.

Research into hybrid systems combining hydraulic and electric actuation could also redefine performance benchmarks, allowing for even greater energy capture and sensitivity to environmental conditions. As solar technology continues to evolve, integrating hydraulic solutions may play an increasingly pivotal role in sustainable energy generation.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF HYDRAULIC OIL CAN BE USED IN SOLAR ENERGY SYSTEMS?

The choice of hydraulic oil is crucial for the efficient functioning of solar energy systems. Traditionally, petroleum-based oils have been widely used due to their good performance characteristics. However, environmental concerns have prompted the development of environmentally friendly fluids, including biodegradable and synthetic oils. These alternatives offer advantages such as lower toxicity and enhanced biodegradability, making them more suitable for solar energy applications situated in sensitive ecosystems.

When selecting hydraulic oil, it’s important to consider factors such as viscosity, thermal stability, and compatibility with system components. Always consult the manufacturer’s guidelines to ensure compliance with recommended specifications. Moreover, biodegradable options can reduce the environmental impact if leaks occur, positioning renewable energy projects as more sustainable in the eyes of stakeholders.

HOW OFTEN SHOULD HYDRAULIC OIL BE CHECKED IN SOLAR SYSTEMS?

Regular inspection of hydraulic oil in solar energy systems plays a pivotal role in maintaining efficiency and performance. A recommended practice is to check hydraulic fluid levels at least once a month, especially in systems experiencing frequent or heavy usage. It’s essential to monitor not only the fluid levels but also the oil’s condition, as factors such as heat and contamination can degrade oil over time.

Another consideration involves seasonal changes in operation; for instance, prior to peak operational periods, conducting a thorough maintenance check, which includes hydraulic oil inspection, can preempt any potential failures. Maintaining a diligent maintenance routine minimizes the risk of extensive repairs and minimizes system downtime associated with hydraulic issues.

HOW CAN LEAKS IN HYDRAULIC SYSTEMS BE DETECTED AND FIXED?

Detecting leaks in hydraulic systems demands a proactive approach, as even minor leaks can lead to significant operational inefficiencies. Regular visual inspections of hoses, fittings, and joints can reveal signs of leakage, such as fluid stains or the presence of oil residue. Utilizing leak detection fluids can also aid in identifying faults, as these substances react visibly with hydraulic oil, highlighting potential sources of leakage.

Fixing the leaks typically involves replacing damaged components, such as hoses or seals, and applying robust tightening techniques to ensure leak-free connections. In more complex scenarios, the entire hydraulic assembly might require assessment to guarantee no other issues are present. Timely detection and rectification of leaks are essential to maintain optimal performance and minimize the environmental impact.

Ensuring hydraulic fluid is adequately managed in solar energy applications is paramount for performance and longevity. Continuous attention to detail in selecting the right fluid, maintaining proper levels, and adhering to best practices can yield significant benefits. Frequent inspections alongside systematic maintenance routines help mitigate issues that could hamper effectiveness, ensuring that installations function reliably. Additionally, integrating sustainable practices enhances the overall ecological footprint of solar energy systems. Future innovations within the hydraulic realm will likely offer further advancements, aligning with global sustainability goals while enhancing the efficiencies of solar installations. By committing to excellence in hydraulic management, stakeholders can maximize energy capture, prolong system life, and uphold an environmentally responsible approach to renewable energy production.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-add-hydraulic-oil-to-solar-energy/