1. Adding gas density to energy storage devices primarily entails three critical steps: adjusting the physical design of the storage solution, ensuring appropriate material selection for optimal gas containment, and implementing monitoring mechanisms for effective management. The integration of gas density can significantly enhance energy storage efficiency and drive innovations in sustainability. 4. The application must comply with safety regulations to prevent hazardous incidents, thus ensuring that the technological advancement serves both environmental and human safety needs.

1. UNDERSTANDING GAS DENSITY IN ENERGY STORAGE

The concept of gas density refers to the mass of gas per unit volume. In the context of energy storage systems, this parameter plays a pivotal role in determining the amount of energy that can be stored and subsequently released. Incorporating gas density into these systems allows engineers and designers to optimize energy retention and enhance overall efficiency.

Maximizing gas density is important not only for efficiency gains but also for economic feasibility. By storing energy more densely, systems can achieve higher energy density without necessitating larger physical spaces. This aspect is crucial in urban environments or locations where space is at a premium. Additionally, when gas density is increased, the energy storage device can potentially draw power from a greater range of sources, contributing to the viability of various renewable energy technologies.

2. ENGINEERING DESIGN CONSIDERATIONS

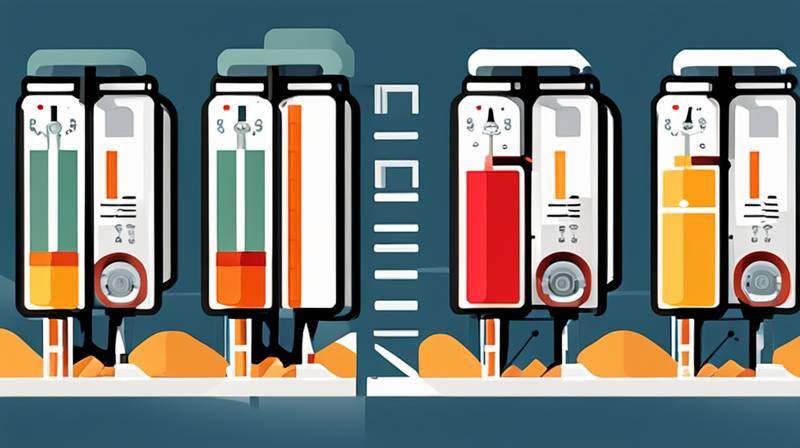

When integrating gas density into energy storage solutions, the engineering design of the device becomes paramount. Considerations include: form factor, material strength, and operational pressures. Devices must be engineered with materials that can withstand the internal pressures exerted by dense gas without risk of rupture or failure.

Moreover, engineers often utilize advanced computational simulations to model how different designs will handle varying gas densities. This is essential for pinpointing any weaknesses in the structure and identifying the materials that will best suit the requirements of the device. Different types of tanks or chambers can be designed with specialized coatings or composite materials to handle the unique characteristics of the gas utilized, whether it be hydrogen, methane, or another choice.

3. MATERIAL SELECTION AND TECHNOLOGICAL INNOVATION

Material selection is a critical aspect of enhancing gas density in energy storage systems. Engineers must choose materials that not only withstand the inherent demands of gas density but also possess conducive properties for energy storage. Composites and alloys that exhibit high strength-to-weight ratios can be particularly effective.

The proper selection of materials also contributes to the longevity and overall sustainability of the energy storage device. Utilizing materials that are recyclable or have lower environmental footprints can enhance system sustainability. Innovations involving materials that change properties under certain conditions can also lead to novel designs. For example, smart materials could potentially adapt as the density and pressure of gases change during operation.

4. IMPLEMENTATION OF MONITORING SYSTEMS

Incorporating monitoring systems is essential for the effective management of energy storage devices that utilize gas density. These systems help track important parameters such as pressure, temperature, and gas composition. Effective monitoring not only ensures optimal performance but also enhances safety by providing early warnings of potential problems.

Advanced telemetry systems can relay real-time data to operators, enabling prompt adjustments or remedial action when necessary. Furthermore, incorporating predictive analytics can help anticipate possible failures before they occur, thus increasing the reliability of the storage system.

5. SAFETY MEASURES AND REGULATIONS

Safety is paramount when working with dense gases in energy storage systems. Regulatory compliance must be considered throughout all stages of design, implementation, and operation. Guidelines established by safety organizations should guide every project to minimize risks associated with gas leakage, explosion, or other critical incidents.

Additionally, engineers must conduct extensive testing to ensure that the storage devices can handle potential misuse scenarios. This involves simulating extreme conditions that could stress test the structure of the device. Safety mechanisms like pressure relief valves and redundant systems should be integrated to prevent catastrophic failures, providing an essential layer of security.

6. FUTURE TRENDS IN ENERGY STORAGE

The future of energy storage systems utilizing gas density points towards several exciting developments. Emerging technologies like supercapacitors and advanced battery solutions are expected to leverage gas density principles. These innovations could enable more efficient energy storage methods that align with green energy goals.

Moreover, research into alternative gases such as ammonia and biogas is increasing, as these materials can offer distinct advantages over traditional options. Continual investment in research and development will likely yield further enhancements in efficiency and operational capacity, further solidifying the role of gas density in future energy storage solutions.

7. FIELD APPLICATIONS AND CASE STUDIES

Real-world applications of gas density in energy storage devices showcase diverse implementations across industries. From renewable energy sectors to automotive industries, several case studies exemplify successful integration strategies. For instance, hydrogen storage has been effectively employed in various applications ranging from fuel cells in vehicles to grid storage systems.

These applications illuminate both the challenges and triumphs faced when integrating gas density concepts. Learning from these case studies facilitates knowledge sharing and helps drive the collective advancement of technology in the energy storage field.

FREQUENTLY ASKED QUESTIONS

WHAT GASES ARE BEST FOR ENERGY STORAGE?

Different gases can be utilized in energy storage systems based on their properties and the intended application. Hydrogen is widely recognized for its high energy content and potential for clean energy solutions. Utilization of hydrogen in fuel cells can provide efficient energy conversion and storage. Methane is another candidate, often leveraged in biogas applications, which is advantageous for its existing infrastructure compatibility.

Additionally, ammonia has gained attention due to its capacity for energy density and ease of liquefaction, enabling efficient storage and transport. Each gas brings unique characteristics, and the selection will ultimately depend on the specific requirements of the energy system in question, including cost, safety, and environmental impact.

HOW DOES GAS DENSITY IMPACT EFFICIENCY?

Gas density directly influences the efficiency of energy storage devices by affecting the energy-to-volume ratio of the stored substance. Higher gas density allows for more energy to be stored in a given volume, thus improving the overall energy efficiency of the device. It also enables lighter and more compact storage systems, which is particularly beneficial in applications where space is constrained.

However, increasing gas density is not without its challenges. The management of pressure and temperature conditions becomes critical, as higher densities can lead to hazardous conditions if not adequately controlled. Efficient designs must balance the optimization of gas density while ensuring the structural integrity and safety of the system.

WHAT ARE THE REGULATORY REQUIREMENTS FOR GAS-DENSE STORAGE DEVICES?

The regulatory landscape for energy storage devices utilizing gas density is multifaceted and varies by location and type of gas employed. Generally, the design and implementation of such systems must comply with local, national, and international safety regulations that govern storage and handling of pressurized gases.

For example, in the United States, the Occupational Safety and Health Administration (OSHA) sets regulations to ensure workplace safety, including clear guidelines for the storage and use of hazardous gases. Similarly, the National Fire Protection Association (NFPA) outlines standards for fire safety. It is imperative for manufacturers and operators to stay informed about regulatory updates and ensure compliance through regular inspections and certifications.

The integration of gas density into energy storage devices represents a significant leap towards enhanced efficiency and sustainability. By focusing on critical aspects such as engineering design, material selection, monitoring systems, and safety regulations, developers can create advanced solutions that respond to modern energy challenges. The future trajectory of this integration will likely unveil even more innovations, as technological advances continue to reshape how energy is stored and utilized. The success achieved through the incorporation of gas density principles will ultimately contribute to a cleaner, more reliable energy landscape, fulfilling the growing global demand for sustainable energy solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-add-gas-density-to-energy-storage-device/