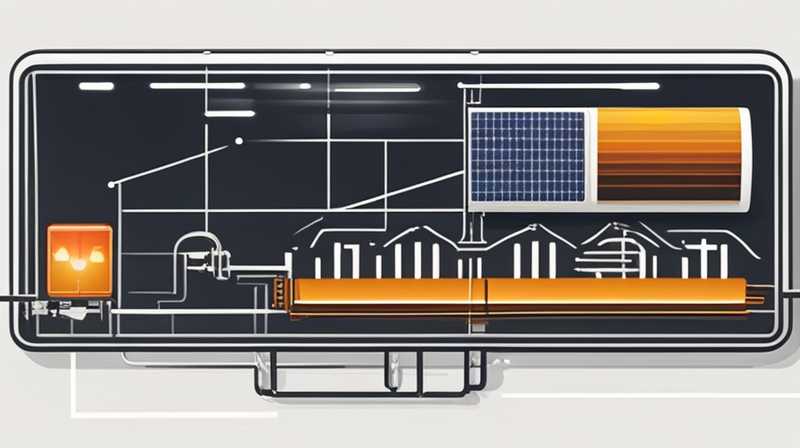

To add antifreeze to a pressurized solar energy system, you will need to follow a systematic process to ensure the system operates efficiently and safely. 1. Understand the importance of antifreeze, 2. Identify the correct type of antifreeze, 3. Prepare the solar heating system, 4. Execute the antifreeze introduction. Proper addition of antifreeze contributes to the longevity of the system and prevents freeze-related damages. This procedure is critical in maintaining the efficiency and functionality of your solar heating system, especially in colder climates. The antifreeze serves to lower the freezing point of the fluid circulating through your solar panels, ensuring that temperature fluctuations do not compromise the system’s performance.

1. IMPORTANCE OF ANTIFREEZE IN SOLAR ENERGY SYSTEMS

Antifreeze plays a pivotal role in the overall functionality of pressurized solar energy systems. Without appropriate antifreeze measures, the fluid circulating through the solar collectors and pipes can freeze when temperatures drop. This can lead to severe and costly damages, including ruptured pipes, leaks, and a complete failure of the solar heating system.

When dealing with solar heating systems, knowing when to introduce antifreeze is imperative. Many systems operate there in climates with a risk of freezing temperatures, making antifreeze not just an option but a necessity. The fluids often used in these systems are water-based, and pure water has a freezing point of 0°C (32°F). In contrast, most commercial antifreezes can lower this freezing point significantly. Choosing the right type of antifreeze can not only help prevent freezing but also contribute to improved heat transfer efficiency.

Moreover, when the temperatures fluctuate dramatically, antifreeze acts as an essential buffer to keep the system functioning optimally. Poorly managed fluid levels can affect the thermal efficiency of the solar panels, leading to subpar energy production and ultimately reduced savings on energy costs.

2. DISTRIBUTING ANTIFREEZE IN PRESSURIZED SYSTEMS

Introducing antifreeze into a pressurized solar energy system requires attention to detail and proper methodology. First, you need to assess your existing fluid levels and determine the volume of antifreeze needed to obtain the right mixture. Several factors influence this assessment, including the size of the system, existing fluid types, and the climate conditions prevalent in your area.

Next, you must ensure that the antifreeze used is compatible with your system. Many systems utilize propylene glycol or ethylene glycol as antifreeze agents. Propylene glycol is often preferred in residential and commercial systems due to its lower toxicity levels, while ethylene glycol is more effective in extreme conditions but comes with potential health hazards if there are leaks. Always check your manufacturer’s guidelines to understand the specifications needed for your solar energy system.

Before the addition, it is essential to flush the existing circulating fluid if it is not the recommended type or if it has been contaminated. To effectively flush the system, use a non-toxic flushing solution and follow the manufacturer’s cleaning procedures to ensure all old fluid is removed before introducing the antifreeze. This step prevents the risk of chemical reactions and maintains overall performance.

3. SAFETY AND PREPARATION PRIOR TO ANTIFREEZE ADDITION

Safety precautions are paramount when working with pressurized systems and antifreeze. Gather all the necessary tools and protective gear, including gloves and goggles, to minimize any risks associated with chemical exposure. Ensure that your work area is well-ventilated, especially when handling antifreeze solutions that can emit vapors.

Before introducing antifreeze, it’s crucial to properly prepare your solar heating system. Start by turning off the pump controlling the system. Always release any pressure in the system to avoid unexpected splashes or leaks of fluid when you open valves or connections. Familiarize yourself with your system’s layout to ascertain where you need to access components safely.

Subsequently, check all hoses, connectors, and seals in your solar heating system for wear and tear. Damaged components can exacerbate issues when new antifreeze is introduced, leading to leaks and system inefficiencies. If any leaks or weaknesses are detected, addressing those concerns ahead of time is vital to ensure a seamless antifreeze addition.

4. EXECUTING THE ANTIFREEZE ADDITION PROCESS

To begin the antifreeze addition process, gather your antifreeze solution and measuring equipment. Insert a funnel into the reservoir or fill port to avoid spills while pouring. Slowly introduce the antifreeze mixture into the system, ensuring that the appropriate antifreeze-to-water ratio is maintained according to the manufacturer’s specifications.

After filling the system, it is essential to power up the pump and allow it to circulate the antifreeze solution throughout the system. Monitor the pressure levels as the antifreeze mixture is introduced; it may take some time for the system to stabilize. During this process, check for any unusual sounds or leaks.

Post-addition, assessing the system to gauge whether the antifreeze is adequately distributed is imperative. Observe temperature fluctuations and pressure readings; they should return to normal operational levels within a short timeframe. If something appears off, re-examine your setup and consider consulting with a professional to prevent further complications.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE BEST TYPE OF ANTIFREEZE FOR SOLAR ENERGY SYSTEMS?

Choosing the best antifreeze for solar energy systems largely depends on the specific requirements of your system and the climate in which you live. Propylene glycol is generally recommended for residential systems. It is non-toxic and poses minimal risks if leaks occur, making it a safer choice for domestic environments. Ethylene glycol, while highly effective, carries higher toxicity levels and should be handled with care.

When deciding, you should also consider the manufacturer’s recommendations. Some organizations may have specific requirements for fluid types to maximize the effectiveness of the system. Additionally, ensure that any antifreeze you select is designed specifically for solar systems, as traditional automotive antifreeze may not be suitable for this application. Always review the Material Safety Data Sheets (MSDS) for your chosen antifreeze to understand its properties before use.

HOW OFTEN SHOULD ANTIFREEZE BE ADDED TO MY SOLAR SYSTEM?

The frequency of antifreeze addition to solar systems can vary widely based on several factors. It is advisable to inspect your solar energy system at least once a year, especially before the colder months. During this inspection, check for the antifreeze levels, concentration, and the general health of the system components.

If tests show that the concentration of antifreeze has dropped below the optimal level due to evaporation or leaks, it may be necessary to add more antifreeze. In regions with extreme temperature fluctuations, more frequent checks may be warranted. Furthermore, if you’ve experienced any leaks during the previous seasons, addressing them immediately and replenishing the antifreeze is critical to maintaining system performance. Keeping a maintenance log can also help remind you of the ideal times to check and refill antifreeze levels.

CAN I USE WATER INSTEAD OF ANTIFREEZE?

Using water instead of antifreeze might seem like a tempting cost-saving measure; however, this practice can lead to severe issues. Water has a freezing point of 0°C (32°F), and in colder climates, it can freeze and expand, potentially resulting in ruptured pipes and damaged components. This situation can cause significant financial repercussions in repairs and lead to inefficiencies in energy production.

Furthermore, even in milder climates, using water alone can cause other complications, such as corrosion within the system. Antifreeze not only lowers the freezing point but also acts as a corrosion inhibitor, helping to protect metal parts from degradation and extending the system’s lifespan. In conclusion, despite the initial cost of antifreeze, it offers protective benefits that far outweigh the risks associated with utilizing plain water.

In summary, adding antifreeze to a pressurized solar energy system is essential for safeguarding mechanical integrity and optimizing function. Preparation is key: assess, choose, and monitor the antifreeze properly. Regular inspections and maintaining the correct antifreeze levels will ensure your system operates efficiently in all seasons, preventing freeze-related damage. To go through the process smoothly, follow the outlined steps and always prioritize safety and material compatibility.

Implementing antifreeze in your solar system will not only prolong its life but also enhance energy efficiency, ultimately leading to better returns on your investment. Always consider consulting with professionals when dealing with complex solar systems, as their expertise can provide additional insights and reassurance to the process. Regular maintenance and a thorough understanding of the fluid dynamics within your solar energy system will contribute to a sustainable and efficient energy solution for your needs.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-add-antifreeze-to-pressurized-solar-energy/