How much water can a pressurized tank store? The capacity of a pressurized tank varies based on several factors including its design, size, and intended purpose. 1. The volume of water that a pressurized tank can hold is largely determined by its dimensions and the material used in its construction, as manufacturers typically design these tanks to accommodate specific pressures. 2. Commonly, these tanks can range from a few gallons to several thousand gallons, depending on their applications such as residential water systems or industrial processes. 3. Additionally, regulations and safety standards must be met, influencing overall design and maximum capacity. 4. Moreover, the efficiency of the pressure management system can impact how effectively the tank can utilize its storage, which is crucial for ensuring a steady supply of water when needed. All these factors collectively determine the operational efficiency and overall water storage capacity of pressurized tanks.

1. UNDERSTANDING PRESSURIZED TANKS

In many sectors, pressurized tanks serve critical roles, from residential water systems to industrial applications necessitating fluid storage. The fundamental purpose of these tanks revolves around storing and dispensing liquids while employing pressure to maintain their integrity and functionality. The ability to control pressure within the tank directly influences several features, including its capacity, efficiency, and safety.

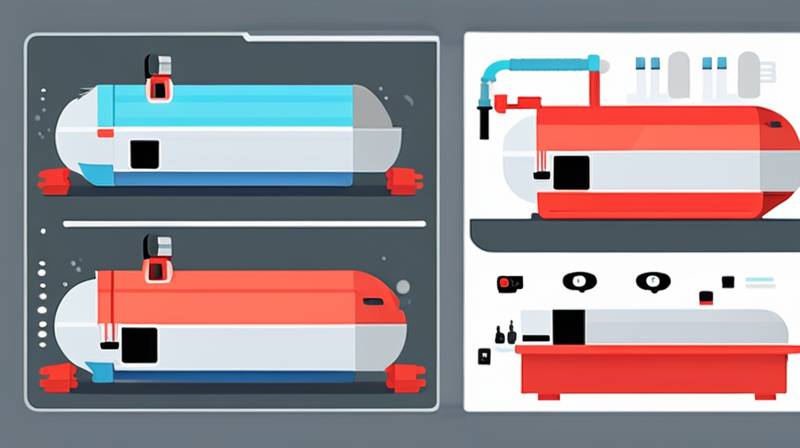

The technology surrounding pressurized tanks has evolved significantly over time. Early designs focused primarily on storage, but modern advancements integrate sophisticated pressure management systems that enhance performance. Such systems ensure that users can draw water without experiencing pressure drops, thus maintaining a consistent supply. Additionally, there are various configurations of tanks, each tailored to specific needs and constraints; for instance, horizontal and vertical tanks may present different storage capacities while occupying similar footprints.

2. CAPACITY DETERMINANTS

Diving deeper into the intricacies of tank storage, multiple variables affect the maximum volume a tank can reliably store. First, tank geometry plays a notable role—cylindrical tanks typically maximize storage due to their ability to handle pressure more effectively compared to shapes such as cubes or spheres. Generally, the larger the diameter and height of a cylindrically shaped tank, the more water it can hold.

The material composition also profoundly influences the storage capabilities. Tanks made from high-grade steel or composite materials can accommodate greater pressures without succumbing to failure. For example, some tanks are designed to withstand pressures exceeding 150 psi, significantly increasing their water storage potential. Conversely, tanks fabricated from less durable materials may not safely achieve the same pressure levels, thereby limiting their storage capacity.

3. APPLICATIONS OF PRESSURIZED TANKS

The realm of pressurized tank usage is broad, encompassing diverse applications. In residential settings, these tanks are primarily used in well water systems to create a consistent water supply. They store water under pressure, allowing for instant access as required by household fixtures. This function is essential, particularly in areas where municipal water supply is inconsistent.

In industrial contexts, pressurized tanks often facilitate processes such as chemical storage or water treatment. These tanks are typically larger in scale and equipped with advanced systems for monitoring and managing pressure levels. The ability to store significant volumes of water or chemicals safely is a necessity in such environments, with designs focusing on both operational efficiency and regulatory compliance. Moreover, industries also utilize pressure tanks for firefighting systems, where high volumes of water must be readily available for emergency situations.

4. REGULATORY STANDARDS AND SAFETY

Safety is paramount when dealing with pressurized tanks given the consequences of potential failure. Regulatory standards dictate how tanks should be constructed, maintained, and operated to minimize risks associated with high-pressure storage. Various organizations, such as the American Society of Mechanical Engineers (ASME), provide guidelines to ensure compliance with safety practices.

Regular inspections and maintenance are also vital for the longevity of pressurized tanks. Operators must routinely check for potential leaks, corrosion, or structural weaknesses that could jeopardize tank integrity. Furthermore, advanced monitoring technologies now allow for real-time pressure readings, alerting operators to unsafe conditions before they escalate into serious incidents. This proactive approach to safety not only protects personnel but also safeguards the stored water and associated systems from potential contamination or failure.

FAQS

WHAT FACTORS AFFECT THE CAPACITY OF A PRESSURIZED TANK?

Several critical elements impact the overall capacity of a pressurized tank. Design specifications, such as dimension and shape, play a major role. For instance, cylindrical tanks generally offer greater storage volume compared to other shapes. Additionally, material type is crucial; tanks made from robust materials like steel can inevitably handle higher pressures, thus increasing their storage capacity. The intended application also influences capacity requirements—residential versus industrial tanks typically have different volume needs. Finally, pressure regulations and safety standards will dictate maximum capacity, ensuring safe operations while meeting storage needs.

HOW LONG CAN WATER BE STORED IN A PRESSURIZED TANK?

The duration of water storage within a pressurized tank depends on several factors, including tank design, water quality, and the presence of certain treatment methods. In general, pressurized tanks can maintain water quality for extended periods, but without proper treatment or circulation, water may become stagnant, leading to potential contamination. Regular maintenance, including cleaning and inspection, can prolong the freshness of the stored water. Factors such as temperature may also play a role in determining water lifespan; warmer conditions may foster microbial growth, while cooler environments can aid in preserving water quality.

CAN PRESSURIZED TANKS STORE OTHER LIQUIDS?

While pressurized tanks primarily serve for water storage, they are also designed to accommodate various liquids depending on their material composition and construction. Many industrial pressurized tanks can store chemicals, oils, or other fluids safely. However, it’s critical to ensure that the tank material is compatible with the specific liquid to prevent degradation or contamination. Furthermore, different liquids may require specific pressure management technologies or safety measures, particularly for those that are hazardous. Ensuring compliance with safety regulations and industry standards is imperative when using pressurized tanks for diverse liquid storage applications.

The significance of pressurized tanks transcends mere storage; they are integral components of various systems requiring efficiency, reliability, and safety. Understanding their capacity and how it is influenced by design, material, and application enables effective management and utilization. Moreover, the evolution of technology and regulatory frameworks has transformed these tanks into sophisticated assets that provide essential services across diverse sectors. Water management systems have become increasingly reliant on pressurized tanks to meet rising demand while ensuring compliance with safety and environmental standards. Whether in residential, commercial, or industrial contexts, the value of well-maintained and appropriately sized pressurized tanks cannot be overstated. Investments in quality tanks, coupled with regular maintenance, will ensure longevity and reliability in water supply and other liquid storage applications. Thus, it’s essential to appreciate the roles these systems play, encompassing both technological sophistication and practical utility in today’s fast-paced world. As such, prospective users must grasp the nuances of pressurized tank storage, ensuring they make informed decisions that align with their specific needs and application requirements, ultimately contributing to efficient resource management.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-much-water-can-a-pressurized-tank-store/