1. NITROGEN AS A FILLING AGENT IN REFRIGERANT ENERGY STORAGE TANKS

2. TYPICAL NITROGEN VOLUME IN USE, SECTOR-WISE VARIATION, PERFORMANCE ENHANCEMENT THROUGH INERT GASES, ECOLOGICAL CONSIDERATIONS RELATING TO NITROGEN USAGE.

3. 1) The volume of nitrogen generally employed in refrigerant energy storage tanks averages between 20 to 30 percent of the total volumetric capacity, allowing for **ideal operational efficiency.

2) Various industries utilize varying amounts of nitrogen depending on specific cooling requirements and system design, leading to differences in nitrogen filling rates.

3) The inclusion of inert gases, particularly nitrogen, aids in performance enhancements by maintaining pressure stability and preventing system corrosion.

4) Environmental advantages associated with nitrogen use include lower greenhouse gas emissions and an improved ecological footprint, aligning with contemporary sustainability initiatives.**

1. TYPICAL NITROGEN VOLUME IN USE

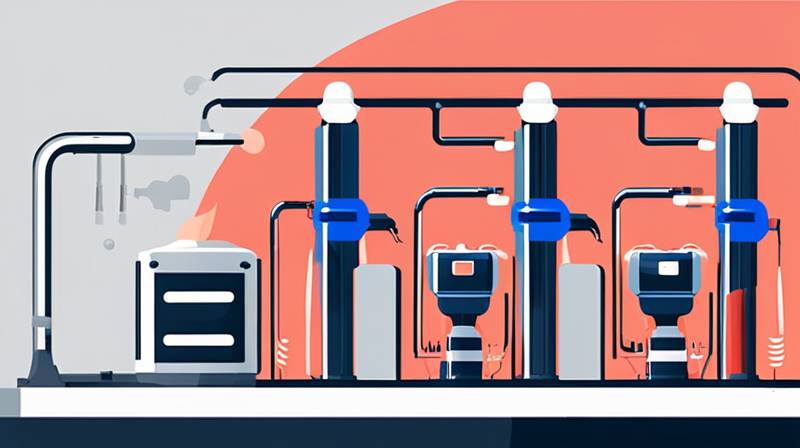

The volume of nitrogen in refrigerant energy storage systems is a critical factor influencing operational efficiency. Engineering standards dictate that approximately 20 to 30 percent of the tank’s total volume is allocated to nitrogen filling. This specific range is essential for maintaining optimal pressure levels, which are vital for effective refrigerant circulation. Unlike other gases, nitrogen remains inert under normal conditions, making it an ideal choice for these applications.

Nitrogen possesses unique thermal properties that afford it the ability to maintain pressure without significantly contributing to temperature fluctuations. Essentially, the use of nitrogen allows systems to operate within desired temperature ranges, minimizing energy expenditure. Therefore, a well-calibrated nitrogen level can translate into significant energy savings, demonstrating the importance of precise filling practices in enhancing the overall performance of refrigerant energy storage tanks.

2. SECTOR-WISE VARIATION IN NITROGEN UTILIZATION

Across different industries, the demand and application of nitrogen in refrigerant energy storage tanks can vary markedly. For instance, sectors such as food preservation are particularly attentive to their nitrogen levels. In these industries, maintaining a pure inert atmosphere is essential to prolonging shelf life and preserving product quality. As a consequence, nitrogen is often utilized at the higher end of the typical volume spectrum.

In contrast, other sectors, such as industrial refrigeration for large-scale operations, may employ lesser percentages of nitrogen filling to accommodate the vast quantities of refrigerant needed for effective cooling. Here, the need for rapid cooling may lead to an adjustment of nitrogen volumes to ensure performance is optimized without compromising safety standards. Recognizing these diverse requirements is vital for engineering tailored solutions capable of addressing sector-specific needs.

3. PERFORMANCE ENHANCEMENT THROUGH INERT GASES

Integrating inert gases like nitrogen into refrigerant energy storage systems yields noticeable benefits. The addition of nitrogen not only serves as a stabilizing factor but also plays a role in mitigating corrosion within the tanks. This corrosion resistance extends the lifespan of equipment, thereby generating cost savings for businesses over time.

Furthermore, nitrogen filling helps in maintaining the desired vapor pressures. This stabilization is crucial for ensuring that the refrigerants function at peak effectiveness. Across various settings, the right balance of nitrogen enables systems to maintain consistent performance by preventing fluctuations that can affect the refrigeration cycles. In the long run, investing in optimal nitrogen management practices signifies a commitment to sustained functionality and reliability.

4. ECOLOGICAL CONSIDERATIONS RELATING TO NITROGEN USAGE

Engaging with nitrogen as a filling agent in refrigerant systems carries significant environmental implications. As a naturally abundant gas in the atmosphere, nitrogen presents minimal ecological risks when applied properly. Utilizing nitrogen minimizes the reliance on environmentally hazardous materials, which are often present in other gases typically used in refrigeration.

Noble gases have an environmental footprint that advocates for sustainability and energy efficiency. Employing nitrogen as a refrigerant filler complements green initiatives within industries striving to reduce their greenhouse gas emissions. Enhanced focus on ecological responsibility translates to a growing preference for nitrogen, aligning with the global push for reduced environmental impact and the shift toward a more sustainable industrial future.

FAQs

HOW DOES NITROGEN COMPARE TO OTHER GASES USED IN REFRIGERANT SYSTEMS?

When evaluating the performance of nitrogen compared to alternative gases, one must consider both environmental and operational efficiency. Nitrogen offers a unique set of features that others do not; chiefly, it exhibits minimal reactivity, which translates to increased safety during operation. Unlike gases that contribute to greenhouse gases when released, nitrogen does not pose a significant ecological threat, aligning with forms of sustainable practices in industrial settings. However, it may not always provide the same thermal properties as some other gases in specific scenarios, necessitating a thorough analysis of requirements before selecting a filling gas.

WHAT EFFECT DOES NITROGEN LEVEL HAVE ON SYSTEM PERFORMANCE?

Proper nitrogen levels are crucial for optimal system performance. A balance must be struck—too high an amount may lead to pressure imbalances, while insufficient levels can result in decreased cooling efficiency. The pressure balance maintained by nitrogen directly impacts the functionality of the refrigerant circulating within the system. Additionally, the inert nature of nitrogen prevents potential chemical reactions that could lead to failures or damage. Thus, rigorous inspections and adherence to recommended volume levels are essential for maintaining high operation standards in refrigerant energy storage systems.

IS THERE A DEPENDENCE ON TEMPERATURE VARIATIONS?

The nitrogen volume in refrigeration energy storage tanks does exhibit a dependence on temperature fluctuations. As temperatures change, gases expand or contract, requiring careful management of nitrogen levels to ensure consistent performance. Under higher temperature conditions, additional nitrogen may be necessary to maintain pressure and prevent unwanted stress on the system. Conversely, in colder temperatures, nitrogen levels might need to be adjusted downward to avoid exaggerating pressure disparities relative to the refrigerant’s behavior. Therefore, continuous monitoring and adaptive strategies to manage nitrogen levels is indispensable for successful operations.

The utilization of nitrogen filling in refrigerant energy storage tanks stands at the intersection of efficiency, performance, and sustainability. The volume of nitrogen employed, typically ranging from **20 to 30 percent, plays a pivotal role in maintaining pressure and ensuring optimal system functionality. Various industries exhibit unique nitrogen usage patterns based on their operational requirements, driving the need for tailored solutions. Furthermore, the inert properties of nitrogen offer significant benefits, notably in minimizing corrosion and optimizing vapor pressures, thereby enhancing overall performance.

From a broader ecological perspective, nitrogen usage aligns with environmental sustainability goals. By minimizing the reliance on more hazardous chemicals, industries can lower their overall ecological footprint and contribute positively to the planet’s health. Consequently, incorporating nitrogen not only serves to elevate system capabilities but also supports a paradigmatic shift toward responsible resource management.

In light of these findings, it is evident that the thoughtful management of nitrogen in refrigerant energy storage systems can lead to lasting benefits, both operationally and environmentally. Organizations that prioritize nitrogen’s role are thus positioned to gain a competitive edge while adhering to modern standards of eco-friendliness. As industries evolve and sustainability continues to gain prominence, the dependence on nitrogen-filled systems is poised to expand, affirming its place as a critical component in refrigerant management strategies.**

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-much-nitrogen-is-filled-in-the-refrigerant-energy-storage-tank/