1. The price of the Shanghai energy storage welding machine varies significantly based on several factors, including specifications, manufacturers, and market demand. 2. Generally, a mid-range model may cost between $10,000 to $20,000. 3. Custom configurations and advanced features can push the price upwards of $25,000 or more. 4. Significant additional costs may include installation, shipping, and warranty options. 5. To get a precise quotation, contacting manufacturers or authorized distributors directly is advisable, as prices fluctuate frequently based on supply chain variables.

1. UNDERSTANDING ENERGY STORAGE WELDING MACHINES

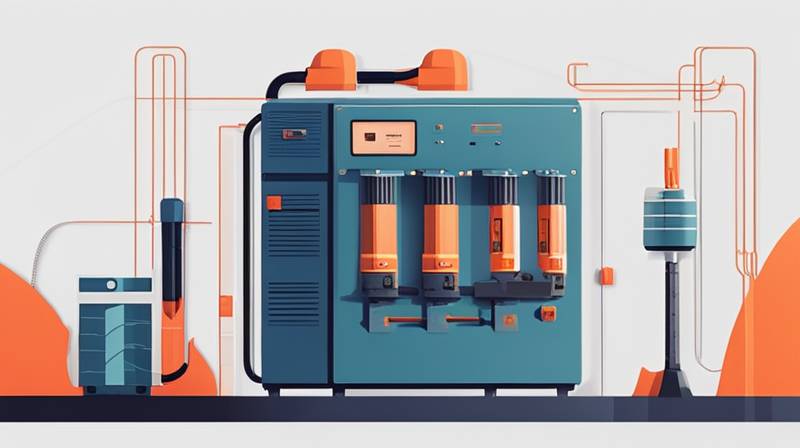

Energy storage welding machines have gained traction due to their efficiency and sustainability in modern industrial applications. This technology harnesses power from various energy sources and utilizes it for welding processes. Traditionally, welding machines have relied on direct energy sources, but significant advancements have led to the integration of energy storage systems. This integration allows for improved control over energy input and output, creating a more efficient work cycle.

Key objectives of these machines include enhanced precision, reduced energy waste, and the ability to weld a wider range of materials under varying conditions. Different configurations are available depending on the application requirements, emphasizing the need to understand the intricacies involved when evaluating price points.

2. FACTORS INFLUENCING COST

Several elements impact the pricing of Shanghai energy storage welding machines. 1. Specifications of the machine: Typically, the complexity of the design and the integration of advanced technology dictate the price. Basic models will generally remain more affordable due to simpler circuitry and fewer components, while sophisticated machines equipped with intelligent energy management systems often demand higher investment.

2. Manufacturer Reputation: Well-established manufacturers with proven track records tend to charge a premium for their products. This pricing reflects their commitment to quality, safety, and customer support services, justifying the higher costs to consumers who prioritize reliability.

3. SPECIFICATIONS AND FEATURES

When evaluating different models, it is crucial to consider the specifications and features that each machine offers. 1. Power Output: The capability of the machine in terms of amps and volts is a significant performance factor. Low-output machines may suffice for small-scale jobs, but high-demand industrial settings require robust machines that can handle intensive tasks.

2. Portability and Size: Some machines cater to specific applications where portability is essential. Smaller machines might have limited functionalities, but they provide flexibility, which large, stationary machines cannot. The choice between portability and power should align with operational needs, directly influencing the machine’s cost.

4. CUSTOMIZATION OPTIONS

Customization can significantly alter the cost of energy storage welding machines. 1. Tailored Solutions: Many manufacturers offer tailored configurations designed to meet unique client requirements or adapt to specific processes. Customization can involve unique features, such as specialized control panels, additional safety mechanisms, or enhanced cooling systems, which will all increase the final price.

2. After-Sales Services: Extra offerings, such as extensive warranties or maintenance packages, can serve as a further layer of customization, ensuring the equipment operates optimally over time. Each added feature or service can influence pricing and affect the total investment required from customers.

5. MARKET TRENDS

The market for energy storage welding machines, particularly in Shanghai, reflects broader trends in sustainability and industrial technology. 1. Growing Demand: As industries increasingly pivot towards eco-friendly operations, energy-efficient welding machines are experiencing heightened demand. Companies are willing to invest more in technology that promises reduced carbon footprints and greater energy efficiency.

2. Technological Advancements: The continual development of smart technologies contributes positively to the pricing landscape. Innovations such as real-time energy monitoring, predictive maintenance alerts, and improved user interfaces enhance machine value but may also lead to higher initial costs.

6. COMPARING PRICE POINTS

Market variability necessitates an in-depth comparison when assessing potential purchases. 1. Entry-Level vs. Premium Models: Entry-level models possess more basic features and lower price points, appealing to hobbyists or small businesses. In contrast, premium models present advanced technologies delivering high performance and operational efficiency while commanding significant prices.

2. Long-Term Value Consideration: It is essential to consider that a high acquisition cost could lead to long-term savings through energy efficiency and less wear and tear. Evaluating options with a holistic view enables more informed decisions aligning with business goals and budgets.

7. POTENTIAL ADDITIONAL COSTS

Acquisition costs represent only one aspect of the machine’s overall financial commitment. 1. Installation and Training: Professional installation and staff training incur additional expenses. Depending on the complexity, many organizations opt for trained personnel from the manufacturer, adding unforeseen costs into the budget.

2. Maintenance Costs: Routine servicing is vital for operational reliability and efficiency. Creating a budget for periodic maintenance helps prevent issues that could disrupt workflow and incur additional repair costs.

8. WHERE TO PURCHASE

Identifying reliable sources for purchasing energy storage welding machines can save potential buyers both time and money. 1. Authorized Distributors: Buying from reputable distributors ensures quality control and access to customer support. Many distributors offer warranties and after-sales services that can enhance the value of the purchase.

2. Direct Manufacturer Contact: Engaging in direct communication with manufacturers can also yield benefits, including the possibility of negotiating prices and customizing the machine to meet specific needs.

9. FINAL THOUGHTS ON INVESTMENT WORTH

An evaluation of the total cost of ownership should form the basis of any purchasing decision. 1. Price vs. Utility: While the upfront cost can seem daunting, considering the long-term operational efficiencies can justify the initial investment. Evaluating machine utility against production demands is vital when making a sound economic choice.

2. Reflections on Vendor Relationships: Establishing relationships with manufacturers or suppliers often leads to better deals, reliable service contracts, and informed choices on new technologies as they become available. Ultimately, investing in a Shanghai energy storage welding machine represents more than just a transaction—it’s about selecting a partner in the production journey.

10. NEED FOR RESEARCH AND ANALYSIS

Diligence in research and analysis will yield decisive benefits when navigating this niche market. 1. Market Analysis: Understanding current trends and innovations assists in making informed choices. Thoroughly assessing competitive models through price, features, and customer feedback ensures that investments align with operational priorities.

2. Financial Planning: Crafting and adhering to a proactive financial plan allows businesses to allocate resources judiciously. Outlining anticipated costs, potential equipment lifespan, and maintenance schedules establishes a clearer picture, guiding future investments in energy storage welding technology.

FREQUENTLY ASKED QUESTIONS

WHAT IS AN ENERGY STORAGE WELDING MACHINE?

Energy storage welding machines leverage energy from various renewable or traditional sources and utilize this stored energy for welding applications. This technology optimizes energy efficiency and performance. By consolidating energy from different stages, these machines can provide consistent power output for diverse welding projects. The mechanisms by which energy storage operates can vary, including capacitors or specific battery systems designed for high-demand industrial applications. Their advantages lie in improving operational efficiency, reducing electricity consumption, and managing energy during peak demands effectively. Additionally, these machines integrate modern controls for precise energy management, making them highly desirable in industries focusing on sustainability.

HOW DOES THE MACHINE IMPACT PRODUCTION EFFICIENCY?

The adoption of an energy storage welding machine can significantly augment production efficiency levels in various industrial settings. First, the precision of energy delivery allows for reduced wastage, promoting better material utilization. The consistent energy provision eliminates fluctuations that can lead to defects in welding quality or longer completion times. Additionally, their capability to charge during off-peak energy periods allows businesses to save on energy costs while optimizing production timelines. The need for fewer machine downtimes also translates into increased overall productivity, making these machines indispensable assets in modern manufacturing environments focused on competitive performance.

WHAT ARE THE BENEFITS OF ENERGY STORAGE TECHNOLOGY IN WELDING?

Energy storage technology offers a myriad of benefits tailored to welding applications. Primarily, it enhances energy efficiency; machines can store energy and deploy it only when necessary, minimizing wastage associated with constant power demand. This feature also allows for flexibility in operations; workers can carry out welding tasks during off-peak hours when energy costs are lower, further optimizing operational budgets. Additionally, modern energy storage systems often incorporate intelligent monitoring systems that provide real-time data, enabling better decision-making and enhanced control over the welding processes. Importantly, utilizing sustainable energy sources through this technology significantly reduces the carbon footprint associated with industrial operations.

The decision to invest in a Shanghai energy storage welding machine requires careful consideration of numerous factors influencing pricing and overall utility. Each prospective buyer should evaluate specifications, manufacturer reputation, customization options, and market trends. A thorough analysis of the functionalities offered, coupled with an understanding of long-term economic implications, will result in informed purchasing decisions. Bear in mind that beyond the initial acquisition cost, other significant financial factors such as installation, maintenance, and training should be accounted for to ascertain the total cost of ownership. Additionally, the move toward sustainability undoubtedly influences market trends, making these advanced machines an appealing option for future-focused industries. Strategic planning, market analysis, and diligent research into vendor relationships can provide essential advantages in this multifaceted investment landscape. Embracing energy storage welding technology not only aligns with contemporary manufacturing practices but also enhances operational efficiency, demonstrating a commitment to innovation and sustainable growth viable for the future of various industries.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-much-is-the-shanghai-energy-storage-welding-machine/