In an inductor devoid of initial energy storage, the price can vary significantly based on specifications and applications. 1. Typically, inductors range from a few cents to several dollars, depending upon size, inductance value, and type; 2. Low-voltage inductors may be less expensive, while high-performance or specialized inductors can command higher costs. 3. It’s crucial for manufacturers and consumers to consider their particular needs, as custom inductors may affect average pricing; 4. Inductors utilized in power applications typically hold higher values due to their performance criteria.

UNDERSTANDING INDUCTORS AND ENERGY STORAGE

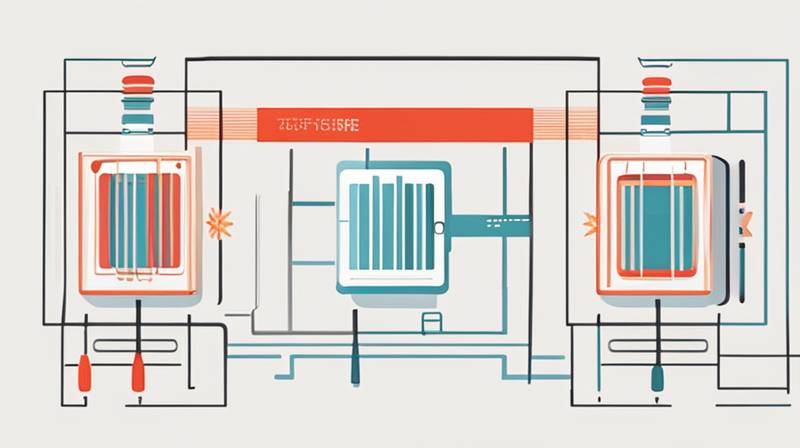

Inductors, fundamentally, are passive electrical components designed to store energy in a magnetic field when an electric current flows through them. Their structure consists of a coil of wire, often wound around a core material, which can be air, ferrite, or iron. When current fluctuates, the magnetic field around the coil changes, inducing a voltage opposite to the change in current. This phenomenon is essential in applications such as filters, oscillators, and transformers, where controlling current and voltage is critical.

The essence of inductance lies in its capacity to resist changes in current. From a physical perspective, when the inductor encounters a change in electric current, the energy conversion occurs: electrical energy to magnetic energy and back again. The lack of initial energy storage indicates that the inductor starts at zero current flow, making its real-world application in certain circuits essential to understand. Proper evaluation of the inductor’s role in circuits without pre-stored energy is vital for effective designs and component choices.

IMPORTANCE OF INDUCTOR PARAMETERS

When assessing inductors, several vital parameters determine their functionality and applicability in circuits. Among these are inductance value, rated current, Q factor, and DC resistance. Inductance, measured in henries (H), indicates the ability of the inductor to store energy. It is one of the primary specifications engineers consider when selecting an inductor for a particular application.

The rated current represents the maximum continuous current the inductor can handle without overheating. Exceeding this threshold can lead to saturation of the core material, which results in a considerable decrease in inductance and potential failure of the component. Q factor measures the efficiency of the inductor and is defined as the ratio of inductive reactance to resistance at a specified frequency. A higher Q factor indicates less energy loss and better performance in high-frequency applications. Similarly, DC resistance should be minimized as it reduces the overall efficiency of the circuit.

MARKET PRICES AND FACTORS AFFECTING COSTS

The pricing spectrum for inductors without initial energy storage can be vast, influenced by various manufacturing and economic factors. Mass production generally leads to reduced prices, while custom or specialized inductors tend to be much more expensive due to their tailored specifications. The materials utilized in the inductor’s construction also play a significant role in its cost. For instance, inductors made with high-permeability ferrite cores may be pricier than those with air cores because of the advanced materials and engineering processes involved.

One major determining factor for pricing is the application context. Standard inductors used in basic circuits may fetch a lower price compared to high-end inductors employed in telecommunications, aerospace, or automotive applications, where reliability and performance are paramount. Market trends, technological advances, and raw material availability can further contribute to fluctuations in component pricing. Understanding these factors aids consumers and engineers in making informed purchasing decisions.

APPLICATIONS OF INDUCTORS WITHOUT INITIAL STORAGE

Inductors without initial energy storage are often employed in various applications that require transient control or filtering. For example, in switch-mode power supplies, inductors manage energy transfer during switching events. Their operation involves rapid changes in current, making energy storage irrelevant at the moment of switching. Instead, the ability of these inductors to act quickly is paramount in achieving efficiency and stability.

Additionally, they find extensive usefulness in filtering applications where no initial energy is essential. By smoothing out voltage spikes and filtering out unwanted frequencies, inductors without initial storage become important in audio electronics, telecommunications, and radio frequency applications. Their instantaneous response to changes in voltage and current results in circuits that perform optimally without energy preconditioning.

CHOOSING THE RIGHT INDUCTOR

Selecting the appropriate inductor involves several critical considerations that extend beyond simple cost assessments. Understanding the specific requirements of the application is vital for making the right choice. This includes evaluating the frequency response, current handling capabilities, and physical space constraints of the circuit design. High-frequency applications typically require inductors with minimal parasitic capacitance and low DC resistance, while low-frequency applications may prioritize inductance value and current rating.

Furthermore, analyzing the thermal properties of the inductor can greatly influence longevity and performance. Factors such as ambient temperature and thermal dissipation capabilities directly impact the inductor’s effectiveness. It is also beneficial to consult datasheets and manufacturer specifications closely, as they provide comprehensive insights into the performance parameters you can expect from each inductor type. By maintaining an awareness of these factors, engineers and designers can optimize their circuit designs to achieve peak performance while controlling costs.

INDUCTOR MANUFACTURING AND DESIGN

The intricacies of designing inductors involve both science and art. Engineers must account for a myriad of physical and electrical parameters during the manufacturing process. Precision in winding techniques, core selection, and annealing processes contributes tremendously to the final inductor’s performance. Additionally, simulation tools and software play a rather crucial role in modern design, enabling engineers to evaluate electromagnetic characteristics and optimize designs virtually before physical production.

Moreover, ongoing advancements in materials science lead to innovations in inductor designs. Modern manufacturers explore novel core materials to enhance inductance and efficiency while reducing size and weight. Such progress allows for better integration into compact electronic devices. The willingness to adopt and adapt new technologies significantly enhances the capacity of inductors to meet the rising demands for compactness and efficiency in ever-evolving electronic landscapes.

FREQUENTLY ASKED QUESTIONS

WHAT IS AN INDUCTOR AND HOW DOES IT FUNCTION?

An inductor is a passive electronic component that stores energy in a magnetic field when electrical current passes through it. Its primary function is to oppose changes in current flow due to its property of inductance. Inductors consist of coils of wire, which may be wound around magnetic materials to enhance their performance. When current enters the coil, it generates a magnetic field that induces voltage opposing the change of current according to Faraday’s Law of electromagnetic induction.

Whether used in filtering applications, energy storage in power supplies, or oscillators in radio frequencies, inductance plays a pivotal role in circuit behavior. A crucial characteristic of inductors is that they resist sudden spikes in current, thereby helping to stabilize circuits. This property proves valuable in smoothening voltage variations and eliminating unwanted noise, making inductors a fundamental component in electronic devices ranging from simple circuits to complex communication systems.

HOW DO I DETERMINE THE RIGHT INDUCTOR FOR MY APPLICATION?

Choosing the right inductor involves assessing several critical factors related to your application’s requirements. Consider parameters such as inductance value, maximum current rating, DC resistance, and frequency response. Start by understanding the specific needs of your circuit: are high frequencies involved where lower resistance and parasitic capacitance are vital? Or is it a low-frequency application that prioritizes inductance value?

Consulting manufacturer datasheets can lead to informed decisions, as they provide detailed insights about performance characteristics and limitations. Additionally, take note of the physical attributes of your application, including space constraints and heat management, since these factors may further influence your choices. Testing inductors in trial environments can also help identify which component meets your desired specifications effectively.

CAN INDUCTORS BE USED IN ALL TYPES OF CIRCUITS?

Inductors have versatile applications in various types of electronic circuits. While they are predominantly found in AC circuits, they also function effectively in DC circuits under certain conditions. Their primary role in AC settings involves filtering, energy storage, and coupling signals, while in DC applications, they may be used for smoothing current and managing transient responses.

However, it’s essential to grasp that not all circuits require inductors. Some circuit designs, especially those aimed at minimizing size and complexity, can operate more efficiently without them. Ultimately, the necessity of an inductor is dictated by the specific operational needs of the circuit in question. A thorough understanding of both circuit functionality and the properties of inductors will help determine their applicability in any electrical design.

With the intricate advantages that inductors provide in various electronic realms, investing time in understanding their roles, behaviors, and effects on circuit performance holds great value for engineers and designers. Their range of use cases suggests indispensable versatility, while demand for specific configurations necessitates thoughtful selections tailored to particular needs in diverse applications.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-much-is-the-inductor-without-initial-energy-storage/