Guangdong pneumatic energy storage equipment costs vary based on multiple factors, specifically: 1. Equipment specifications, 2. Manufacturer, 3. Installation requirements, 4. Maintenance agreements. To elaborate, the specifications play a critical role in determining the price since more advanced systems that offer higher efficiency, storage capacity, and additional features will command higher costs. The variety of manufacturers also implies a range of pricing strategies, while the installation process can add unexpected expenses depending on the technical challenges presented at the installation site. Maintenance agreements can involve ongoing costs that must be factored into the overall investment.

1. INTRODUCTION TO PNEUMATIC ENERGY STORAGE

Understanding pneumatic energy storage demands a comprehensive look at its operational mechanics. Pneumatic energy storage systems utilize compressed air to store energy, making them a unique solution for energy management. The process begins with compressing air, which gets stored in a reservoir. The stored compressed air can later be released to drive turbines and generate electricity when needed. This method of energy storage is particularly beneficial in balancing supply and demand fluctuations, especially with the increasing penetration of renewable energy resources.

The principle behind pneumatic energy storage systems is tied to concepts of thermodynamics and fluid dynamics. By leveraging the compressive properties of air, these systems ensure a reliable energy source while promoting sustainability. Furthermore, pneumatic energy storage technology can complement renewable energy initiatives. As nations aim for reduced carbon footprints, advancements in pneumatic systems align well with the broader goal of transitioning to sustainable energy solutions.

2. ASSESSING COST FACTORS

When exploring the investment intro pneumatic energy storage solutions, several cost-driving components merit examination. Factors such as the scale of the system, technological advancements, and local regulatory frameworks significantly influence pricing. These components can dramatically shift the investment landscape, making a thorough assessment essential before any purchasing decisions.

The scale of the storage system itself is the primary determiner of cost. Larger systems, which offer greater energy capacity and multiple operational benefits, will naturally cost more. Additionally, the technological sophistication of the equipment itself plays a pivotal role. Modern systems utilize advanced materials and control technologies, resulting in enhanced performance but potentially higher costs. Buyers must balance the urgency of energy demands against the potential for long-term savings derived from more advanced technology.

3. COMPONENTS OF PNEUMATIC ENERGY STORAGE EQUIPMENT

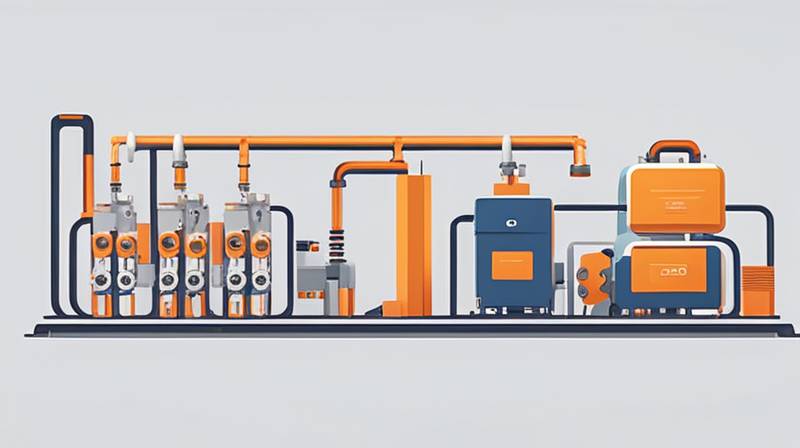

Delving deeper into the specific components that make up pneumatic energy storage systems reveals a myriad of options and considerations. Key elements include compressors, storage tanks, pneumatic controls, and related infrastructure. Each of these components contributes to the system’s efficiency and operational performance, which directly impacts the total investment.

Compressors are essential for the initial air compression process. Their effectiveness directly correlates with the system’s overall performance. Additionally, storage tanks need to be constructed from durable materials that can withstand high-pressure conditions without compromising safety. Pneumatic control systems facilitate the precise monitoring and management of air pressure, ensuring optimal energy release during electricity generation. By understanding these components, potential purchasers can make informed decisions about the equipment mix that will yield the best results.

4. INSTALLATION AND MAINTENANCE COSTS

Installation and maintenance expenditures form a significant component of the total investment in pneumatic energy storage systems. Installation costs can fluctuate depending on geographical location, complexity of the installation site, and additional engineering requirements. Proper installation is paramount, as improper setup can lead to inefficiencies or safety concerns.

Regular maintenance is equally critical, impacting long-term operational costs. Maintenance typically includes scheduled inspections, equipment repairs, and unforeseen replacements. Establishing a robust maintenance agreement with service providers ensures that the equipment remains functional and efficient throughout its lifespan. By factoring these ongoing costs and initial investments into the overall budgeting for pneumatic energy storage, organizations can avoid unexpected financial burdens.

5. INDUSTRY APPLICATIONS AND BENEFITS

The versatility of pneumatic energy storage systems means they can be effectively employed across various industries. Applications range from renewable energy integration to grid stability and peak shaving solutions. In the context of renewable energy, pneumatic systems can provide backup energy during periods when solar or wind energy generation falls short, thereby maintaining reliability in power supply.

Moreover, industries requiring intense energy demands during peak hours can leverage pneumatic systems to alleviate load on the grid, thus managing costs more efficiently. This application extends the benefits beyond mere energy savings. Organizations can improve their sustainability profiles and align with governmental sustainability regulations, ultimately leading to a competitive edge in increasingly eco-conscious markets.

6. GOVERNMENT INCENTIVES AND REGULATIONS

Government regulations and potential incentives significantly shape the economic landscape surrounding pneumatic energy storage solutions. Subsidies and incentives aimed at promoting renewable energy technologies can substantially offset initial investment costs. These financial aids create opportunities for manufacturers and end-users to explore pneumatic energy storage options that might have been financially prohibitive otherwise.

Equally important are local regulatory considerations. Compliance with environmental standards and safety regulations must be anticipated in operational plans. Firms that remain ahead of these requirements often benefit from reduced bureaucratic hurdles and expedited permitting processes. Understanding and integrating these regulatory frameworks into the planning phase not only enhances project feasibility but ensures alignment with broader community and environmental goals.

7. FUTURE TRENDS IN PNEUMATIC ENERGY STORAGE

The future of pneumatic energy storage appears promising, with several evolving trends on the horizon. Innovations in materials and technology are facilitating the development of more efficient systems that promise to lower operational costs and enhance performance. Advances in data analytics and control systems are enabling greater precision in air management and usage, ultimately maximizing the return on investment.

Moreover, as global emphasis on clean energy accelerates, pneumatic energy storage is likely to gain traction as a preferred option within sustainable energy portfolios. Its compatibility with other renewable technologies, such as wind and solar, will enhance its profile as a viable solution in energy diversification strategies. Stakeholders must stay informed of these trends to remain competitive and capitalize on emerging opportunities in the energetic landscape.

FAQs

WHAT ARE THE KEY ADVANTAGES OF PNEUMATIC ENERGY STORAGE?

Pneumatic energy storage systems present numerous advantages, most notably in energy efficiency and sustainability. These systems are capable of providing reliable, rapid energy backup during peak demand times. They can harness excess energy from renewable sources, mitigating the inefficiencies of intermittent energy production. The technology also benefits from being environmentally friendly, as it primarily utilizes clean air and avoids emissions associated with other forms of energy storage.

Moreover, these systems require less infrastructure than comparable storage solutions, such as pumped hydro systems. This results in lower costs and faster implementation timelines. Additionally, pneumatic systems can be scaled according to energy needs, providing adaptability that is crucial for energy management in various industries. Overall, pneumatic energy storage represents a progressive shift toward more sustainable energy solutions, offering both economic and environmental benefits.

HOW DOES PNEUMATIC ENERGY STORAGE COMPARE TO OTHER ENERGY STORAGE METHODS?

Pneumatic energy storage offers distinct advantages and disadvantages compared to other energy storage methods such as battery storage and pumped hydroelectric systems. One of the key factors is scalability, as pneumatic systems can be adjusted in size more readily to meet varying energy demands. This flexibility allows facilities to optimize their energy usage based on real-time requirements.

In contrast, battery storage typically provides lower upfront costs but can incur higher replacement expenses and have shorter lifespans. Moreover, the environmental impact of battery materials can pose ethical concerns. On the other hand, pumped hydro systems are limited by geographic constraints and may require significant infrastructure investments, while pneumatic systems can be installed more flexibly. Ultimately, the choice between pneumatic and other energy storage methods should hinge on the specific energy needs, geographical context, and economic goals of the implementing facility.

WHAT FACTORS SHOULD BE CONSIDERED WHEN PURCHASING PNEUMATIC ENERGY STORAGE EQUIPMENT?

Acquiring pneumatic energy storage equipment necessitates careful consideration of several critical factors. System capacity and efficiency are foremost in decision-making, as these metrics dictate how effectively the facility can meet energy demands. Equipment specifications, including the technology used and the quality of materials, directly influence the operational performance and lifespan of the system.

Additionally, potential purchasers should evaluate installation costs and spatial requirements, ensuring the facility can accommodate the necessary infrastructure. Long-term maintenance needs and service agreements are also paramount considerations; understanding the ongoing support required can prevent unanticipated expenses down the line. By thoroughly evaluating these aspects, stakeholders can make well-informed purchasing decisions that align with their operational goals.

Ultimately, the investment in pneumatic energy storage equipment represents a forward-thinking approach to energy management. Key economic, environmental, and operational advantages illustrate its significance as a catalyst for sustainable energy practices. Organizations positioned to leverage these systems can prepare for rapid advancements in energy technologies, thereby ensuring both resilience and efficiency in their operations. Incorporating enhanced pneumatic storage into existing energy frameworks complements broader objectives of transitioning towards cleaner, more sustainable energy solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-much-is-guangdong-pneumatic-energy-storage-equipment/