How much is a hydraulic accumulator

The cost of hydraulic accumulators can vary significantly based on several factors. 1. Type of accumulator: Different types, such as bladder, piston, or diaphragm accumulators, have varied price ranges. 2. Capacity and specifications: The size and pressure rating play crucial roles in determining the price. 3. Brand and quality: Reputable manufacturers with a history of high-quality products often charge more than lesser-known brands. 4. Market conditions: Fluctuations in raw material costs, demand, and economic factors can influence pricing. Understanding these factors is essential when considering a purchase, as they directly affect the value and performance of the hydraulic system.

1. EVOLUTION OF HYDRAULIC ACCUMULATORS, CONSTRUCTION AND DESIGN

Hydraulic accumulators have undergone significant progress since their inception, deriving from simple mechanical systems to sophisticated devices crucial for modern hydraulic applications. These devices store energy in the form of pressurized hydraulic fluid and are integral for ensuring stable hydraulic system performance.

In the early days, hydraulic accumulators were rudimentary vessels that functioned primarily as energy storage devices. Over time, they evolved into more complex units, incorporating advanced designs like bladder and diaphragm systems. This evolution led to enhanced reliability, efficiency, and functionality, allowing hydraulic systems to become more compact while maintaining or increasing their output capacity.

The construction of a hydraulic accumulator involves several key components. These include the main cylinder, a gas-charged diaphragm or bladder, and various fittings and seals. The understanding of material properties and capabilities, such as resistance to pressure and temperature fluctuations, has greatly influenced accumulator design, resulting in devices that can withstand challenging operational conditions while providing consistent support to hydraulic systems.

2. TYPES OF HYDRAULIC ACCUMULATORS, COMPARATIVE ANALYSIS

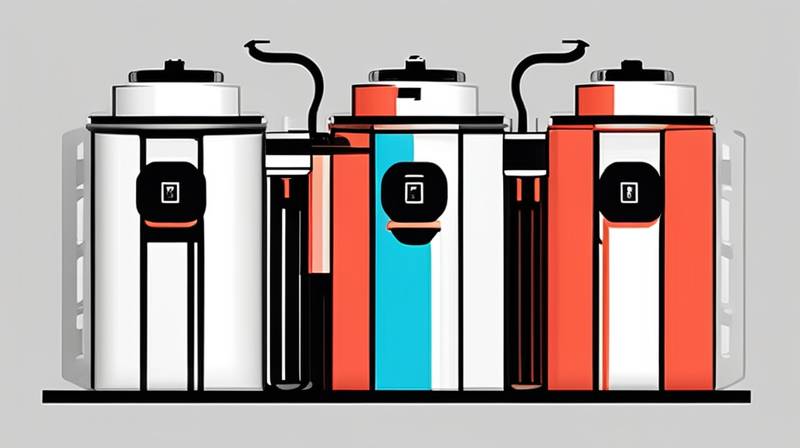

Multiple categories of hydraulic accumulators exist, each providing unique benefits and functionality within hydraulic systems. Among the most common types are bladder accumulators, piston accumulators, and diaphragm accumulators. Each type serves specific purposes and is applicable in various scenarios, influenced by their construction, pressure capacities, and application areas.

Bladder accumulators consist of a flexible bladder where hydraulic fluid is separated from a gas charge. This configuration makes bladder accumulators particularly adaptable to a variety of applications. Their ability to absorb shocks and maintain pressure makes them suitable for systems prone to fluctuations, especially in sectors like agriculture and manufacturing.

Piston accumulators utilize a movable piston to separate the fluid and gas, functioning effectively in high-pressure applications. The adaptability of piston accumulators provides excellent volume capacity relative to their size, allowing them to be effective in hydraulic circuits requiring increased storage capacity. In contrast, diaphragm accumulators, which employ a diaphragm to separate gas and fluid, provide compact options ideal for lower-pressure applications where precision and control are vital.

3. FACTORS AFFECTING COST, DETAILED EXPLORATION

The market for hydraulic accumulators is influenced by various critical factors that affect pricing and accessibility. Understanding these underlying factors can significantly impact purchasing decisions and long-term costs for businesses utilizing hydraulic systems.

Firstly, type and capacity are paramount in determining the price of hydraulic accumulators. Trends indicate that larger and more advanced models demand higher prices due to their enhanced performance characteristics. Smaller applications may require less robust designs, resulting in cost efficiency but potentially compromising functionality during intense operations.

Secondly, brand reputation plays a significant role. Established manufacturers often ensure higher quality standards and extensive warranties, justifying the price differences. Organizations may opt for cheaper alternatives; however, they might encounter hidden costs associated with increased failure rates, maintenance, and consistent performance issues caused by inferior materials and design methodologies.

Market conditions also play a pivotal role in influencing prices. Economic factors, such as inflation rates and raw material availability, can affect production costs, subsequently impacting consumer pricing. Businesses must keep abreast of industry trends and forecasts related to market behavior to anticipate potential price fluctuations and secure favorable purchasing arrangements.

4. APPLICATIONS OF HYDRAULIC ACCUMULATORS, INDUSTRY INSIGHTS

The diversity of hydraulic accumulator applications is astounding, showcasing their relevance across multiple industries. Their primary functions include energy storage, pressure stabilizing, and surge dampening. These critical roles enhance the performance and longevity of hydraulic systems, erasing inefficiencies that could lead to costly downtime during operations.

In the industrial sector, hydraulic accumulators find extensive adoption in applications requiring precise pressure control and rapid response, such as in plastic molding, metal stamping, and assembly lines. By maintaining consistent pressure, hydraulic accumulators prevent system overload and ensure smooth performance, which is crucial in environments with high operational demands.

Moreover, in the field of renewable energy, hydraulic accumulators are used to store energy generated by devices like wind turbines and hydraulic power systems. This energy storage capability enables a smooth delivery of power, optimizing energy use while maintaining grid stability. Such applications underline the versatility of hydraulic accumulators and their role in supporting green technology.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE MAIN ADVANTAGES OF USING A HYDRAULIC ACCUMULATOR?

Hydraulic accumulators offer a multitude of advantages that enhance the efficiency and reliability of hydraulic systems. One of the primary benefits is energy storage, allowing systems to store hydraulic fluid under pressure for later use. This capability ensures that hydraulic circuits can handle peak demands without requiring additional pumps, which would otherwise increase operational costs.

Another significant advantage is pressure stabilization. Hydraulic accumulators can absorb pressure surges or drops, maintaining consistent system performance and preventing damage from excessive pressure changes. This characteristic is particularly valuable in applications involving fluctuating loads or variable speed drives, as it not only prolongs equipment life but also ensures smoother operations.

Moreover, hydraulic accumulators contribute to improved safety standards. By providing an emergency power supply, they enable systems to maintain control during failures, minimizing risks associated with sudden hydraulic failures. These features prove crucial in environments where precise control and safety protocols are paramount, illustrating the essential role of accumulators in modern hydraulic systems.

HOW DO I CHOOSE THE RIGHT HYDRAULIC ACCUMULATOR FOR MY SYSTEM?

Selecting the appropriate hydraulic accumulator necessitates a comprehensive understanding of the application requirements and operational conditions. Begin by assessing the system’s pressure and volume requirements. Ensuring that the accumulator can support these parameters is critical for efficiency and effectiveness during operations.

Next, consider the type of accumulator that aligns best with your application needs. Different types, such as bladder or piston accumulators, offer unique advantages depending on the requirements of the hydraulic circuit. It’s paramount to analyze the nature of the load, frequency of pressure oscillations, and required performance for specific tasks.

Utilizing analysis tools, such as pressure drop calculations and flow rate assessments, can facilitate informed decisions. Collaborating with industry experts or hydraulic engineers can also provide insight into various options, ensuring that the chosen accumulator integrates seamlessly into the hydraulic system while meeting both operational specificities and safety regulations.

WHAT IS THE AVERAGE LIFESPAN OF A HYDRAULIC ACCUMULATOR?

The lifespan of a hydraulic accumulator can vary widely based on multiple factors, including design, materials, and operational conditions. Typically, high-quality accumulators can last anywhere from 10 to 30 years, given that they are properly maintained and operated within their specified limits.

Routine maintenance and regular inspections are paramount for prolonging the life of hydraulic accumulators. Regularly checking for leaks, verifying gas pre-charge, and ensuring overall hydraulic system cleanliness minimize wear and tear, allowing accumulators to function optimally over extended periods.

Environmental factors, such as temperature fluctuations and chemical exposure, can affect lifespans. In harsh operational settings, the equipment may experience accelerated degradation. Users should implement monitoring systems that track performance metrics, ensuring proactive responses to any signs of wear or impending failures, ultimately safeguarding equipment longevity.

In essence, the cost of hydraulic accumulators reflects numerous interrelated factors that influence both pricing and functionality. Their vital presence in various industries underscores their importance in modern hydraulic systems. With a solid understanding of the various types, construction, and applications, users can make informed purchasing decisions that align with operational needs and budget constraints. Such knowledge ultimately contributes to optimized system performance, enhancing overall efficiency and safety.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-much-is-a-hydraulic-accumulator/