The cost of 180mm solar silicon wafers can vary significantly depending on various factors such as market demand, supplier pricing, and fluctuations in raw material costs. 1. As of the latest data, the price range for these wafers is approximately $0.15 to $0.50 per wafer, with prices potentially fluctuating based on conditions in the global market. 2. The price may also be influenced by technological advancements in production processes, which can lead to reduced manufacturing costs. 3. Understanding the pricing dynamics of silicon wafers is essential, especially for manufacturers and investors in the solar energy sector. 4. Recent trends indicate that as solar technology becomes more efficient, the price may stabilize or even decrease, making solar energy more accessible. Therefore, individuals and organizations looking to invest in solar energy should monitor these price changes closely to make informed decisions.

1. MARKET OVERVIEW AND TRENDS

The global market for solar silicon wafers has been experiencing a substantial shift over the last decade, driven by increasing demand for renewable energy and technological advancements in solar technology. The production of silicon wafers plays a crucial role in the manufacturing of photovoltaic (PV) cells, which convert sunlight into electricity. As the world seeks sustainable alternatives to fossil fuels, the solar industry has gained significant traction, leading to a corresponding growth in the demand for solar silicon wafers.

The increasing investment in renewable energy, particularly in solar technology, has led to an escalation in the production of solar silicon wafers. Governments worldwide are implementing policies and incentives to promote solar energy, contributing to this trend. Additionally, many nations have set ambitious targets for reducing carbon emissions, which necessitates a shift toward cleaner energy sources. As a result, the global solar wafer market is projected to experience consistent growth, underpinning the long-term viability of solar technology.

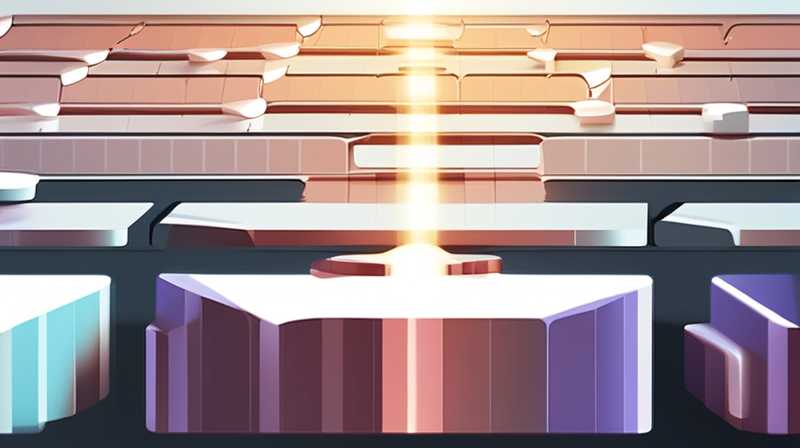

The rise of innovative technologies, such as bifacial solar panels and more efficient solar cells, has further influenced wafer production. These advancements have paved the way for more effective use of silicon wafers, which leads to enhanced energy conversion rates and improved overall system efficiency. Consequently, manufacturers are increasingly focusing on optimizing wafer production processes to meet the evolving demands of the market.

2. FACTORS INFLUENCING PRICES

Several variables impact the pricing of 180mm solar silicon wafers, creating a complex environment for stakeholders. Supply and demand dynamics are the principal factors driving price fluctuations. If demand for solar energy surges, it leads to increased demand for silicon wafers, prompting manufacturers to raise prices. Conversely, during periods of surplus production or reduced demand, prices may decline.

Another critical factor is the cost of raw silicon, which is the primary material for wafer production. Changes in the availability and cost of silicon due to global market fluctuations can significantly influence wafer pricing. For example, if the mining and refining of silicon are disrupted or if geopolitical tensions arise in major producing countries, the price of silicon can stabilize or potentially skyrocket, impacting the cost of wafers.

Technological advancements also play a pivotal role in wafer pricing. As production processes become more energy and resource-efficient, the cost of manufacturing wafers may decrease. Innovations such as new purification techniques and automated manufacturing processes can lead to lower operational costs for manufacturers. Hence, companies that invest in such technologies can maintain competitive pricing strategies, benefiting from economies of scale.

3. IMPLICATIONS FOR THE SOLAR INDUSTRY

The price of solar silicon wafers has far-reaching implications for various players in the solar industry, including manufacturers, installers, and end-users. For manufacturers, fluctuating wafer prices can directly impact overall profitability. Consistently high prices may compel some manufacturers to reconsider their production strategies or invest in more efficient technologies. Conversely, a decline in wafer prices could benefit manufacturers by driving demand.

Solar installers also feel the effects of wafer pricing through the overall cost of solar energy systems. As silicon wafer prices drop, the installed price of solar systems tends to fall as well, making solar energy a more attractive option for consumers. This trend can boost the adoption of solar energy, ultimately fostering a stronger market presence for installers and system providers.

For end-users, the implications are evident in the affordability of solar energy. With lower material costs, the economic viability of investing in solar power becomes more appealing. Homeowners and businesses may begin to view solar energy as a sustainable investment, with shorter payback periods and increased returns. On a broader scale, the competitive pricing of solar systems could help accelerate the transition to renewable energy sources globally.

4. FUTURE PROSPECTS

Looking ahead, the future of solar silicon wafers appears promising, characterized by steady growth and advancements in technology. As the demand for renewable energy continues to escalate, manufacturers are likely to ramp up production to meet both current and future market needs. The ongoing development of new technologies, such as higher-efficiency solar cells and the integration of artificial intelligence in production, will further optimize wafer output.

The move towards environmentally friendly and sustainable practices is another significant trend shaping the future landscape. Many manufacturers are increasingly adopting green production methodologies, which not only help reduce costs but also meet the growing demand for sustainably sourced products. This shift towards sustainable manufacturing practices is expected to become a key differentiator in a competitive market.

Moreover, the price of solar silicon wafers may stabilize over time as supply chains improve and production techniques evolve. The anticipated advancements in both silicon sourcing and wafer production will likely create a more efficient market. As a result, the solar industry may witness a more predictable pricing trend that benefits all stakeholders involved.

FAQs

WHAT ARE SOLAR SILICON WAFERS?

Solar silicon wafers are thin slices of silicon crystal used in the production of photovoltaic (PV) cells, which convert sunlight into electricity. These wafers are typically produced from refined silicon ingots and are a crucial component in solar panels. Their size and purity significantly influence the efficiency and effectiveness of the solar cells they are a part of. Wafer thickness and quality also impact overall solar panel performance, making research and development in this area critical for improving energy conversion rates.

The production of solar silicon wafers involves intricate processes, including crystal growth, slicing, and surface treatment. Manufacturers strive to optimize these processes to reduce costs while maintaining high-quality standards. As technology continues to advance, innovations in wafer production techniques have driven improvements in energy efficiency and reduced the environmental impact of manufacturing processes.

HOW DO TECHNOLOGICAL ADVANCEMENTS AFFECT WAFER PRICES?

Technological advancements greatly influence the pricing of solar silicon wafers by improving manufacturing efficiencies and reducing costs. Innovations in production techniques, such as the development of more efficient cutting methods and the use of high-purity silicon, can lower operational expenses and enhance output quality. As a result, companies adopting new technologies are often able to adjust their pricing structures to remain competitive in the market.

Furthermore, advancements in solar technology, such as bifacial solar cells and concentrated solar power systems, increase the demand for specific types of wafers. This shift can impact the supply and pricing dynamics as manufacturers work to meet evolving market needs. Overall, continuous technological improvements play a pivotal role in shaping the economic landscape of solar silicon wafers and contribute to ongoing efforts to make solar energy more accessible.

WHAT INFLUENCES THE GLOBAL SUPPLY CHAIN OF SOLAR WAFERS?

Numerous factors govern the global supply chain of solar wafers, including raw material availability, geopolitical dynamics, production capabilities, and trade policies. Silicon, the primary raw material for wafer production, is sourced from various countries, making global trade policies essential in determining supply stability. Changes in export restrictions or tariffs can affect pricing and availability, forcing manufacturers to adapt their strategies accordingly.

Additionally, fluctuations in demand driven by changes in energy policy worldwide can impact the supply chain. For instance, increased focus on renewable energy in many countries can lead to spikes in demand for solar wafers, thus affecting the overall market dynamics. Finally, natural disasters and logistics challenges can disrupt the supply chain, highlighting the importance of comprehensive risk management strategies across the solar industry.

In summary, the price and supply dynamics of 180mm solar silicon wafers reflect a complex interplay of market demand, technological advancements, and global supply chain factors. These wafers are critical to the solar energy sector, influencing costs, adoption rates, and the overall sustainability of energy solutions worldwide. Therefore, stakeholders, including manufacturers and consumers, must remain vigilant in monitoring pricing trends and innovations within this rapidly evolving landscape. A deeper understanding of these components is essential for making informed decisions in the pursuit of a cleaner, renewable energy future. As the world continues to prioritize sustainable energy practices, innovations in wafer technology and manufacturing processes will likely play a pivotal role in transforming the solar industry and making renewable energy more accessible and economically viable for everyone.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-much-is-180-solar-silicon-wafer/