The cost of the energy storage nut projection welding machine varies widely based on several factors. 1. The price typically ranges from $10,000 to $100,000, depending on brand and specifications. 2. Customization options can significantly increase the price. 3. Maintenance and operational expenses should also be factored into the overall cost, impacting long-term budget considerations. Furthermore, financing options and regional market conditions may affect pricing strategies for potential buyers.

1. UNDERSTANDING ENERGY STORAGE NUT PROJECTION WELDING MACHINES

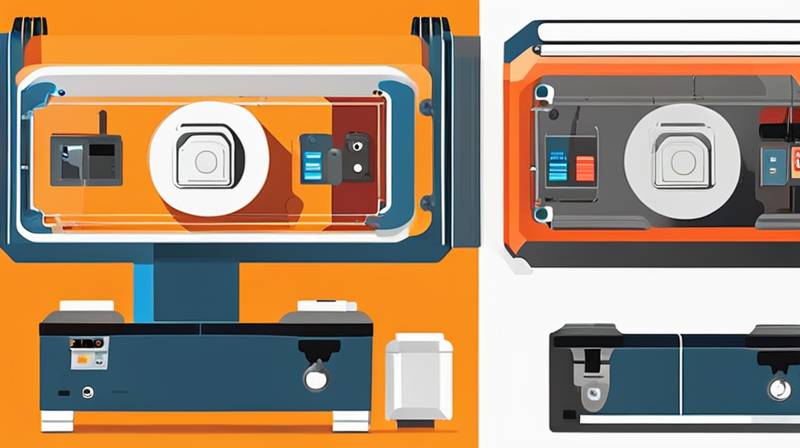

Energy storage nut projection welding machines represent a pivotal technology in modern manufacturing, specifically in the production of components that require the secure attachment of a nut to a component without harming the surrounding material. To truly grasp the dynamics of their pricing and related factors, it is essential to analyze the various elements that contribute to costs associated with acquiring and operating such machinery.

Projection welding, as a method, utilizes the thermal energy produced from electric currents to join two pieces of metal together. This technique offers a multitude of advantages, such as rapid joining processes and minimized distortion of metal parts. By focusing on energy storage methods, manufacturers can create equipment optimized for efficient electrical consumption, enhancing operational capabilities while potentially diminishing overall energy costs in production. Understanding these aspects can provide valuable insight when evaluating both the initial investment and the long-term advantages of utilizing these machines in a particular production environment.

2. FACTORS INFLUENCING THE COST OF THESE MACHINES

Multiple factors contribute to the overall cost of energy storage nut projection welding machines. The most significant considerations include machine specifications, manufacturer reputation, customization, and geographic location. Assessing each of these dimensions can yield critical insights into budgeting processes and market positioning.

Machine specifications play a crucial role in determining pricing. Variations such as power capacity, size, operational speed, and control features directly impact performance and manufacturing efficiency. Companies seeking to enhance production capabilities must assess whether a low-capacity machine fits their needs or if they require higher specifications better suited to intensive operations. Generally, machines with advanced features and higher power capacities command a premium price tag, reflecting their enhanced capabilities in the manufacturing process.

Manufacturer reputation also significantly influences the pricing dynamics of these machines. Established brands often charge more for their products due to their proven track record of reliability and performance. These manufacturers typically invest in research and development, ensuring that their machines incorporate cutting-edge technology. As a result, consumers may find themselves willing to pay a premium for branded machines that promise durability, maintenance support, and overall performance. Consequently, potential buyers should conduct thorough research to compare different manufacturers and assess the value propositions offered.

3. CUSTOMIZATION OPTIONS AND THEIR IMPACT ON PRICE

Customization is another substantial influencer of the cost of energy storage nut projection welding machines. Depending on specific manufacturing requirements, potential buyers may need to modify machine features to align more closely with their production processes. These customizations could vary from enhanced control systems to unique configurations tailored for particular applications.

Customization options may include changes in weld parameters, such as speed, pressure, and energy output, to achieve optimal results for specific materials or product designs. Additionally, alterations related to machine size and ergonomic factors could also be requested, particularly for operations that require compact equipment to fit into constrained production spaces. When procuring a customized machine, it is essential to understand that the increased cost stems from both the engineering resources involved and the production time needed to create equipment tailored to precise requirements.

Furthermore, accessories and add-ons can also be significant contributors to the overall price tag. Add-ons may include automatic loading systems, advanced control panels, or integrated safety features that improve operational efficiency and protect workers from potential hazards. Each of these enhancements inevitably increases the total cost, making it essential for prospective buyers to evaluate their need for such custom features thoroughly.

4. LONG-TERM MAINTENANCE AND OPERATIONAL EXPENSES

While the initial acquisition cost of energy storage nut projection welding machines is a primary concern for most companies, long-term maintenance and operational expenses cannot be overlooked. Understanding ongoing costs is crucial for effective budgeting and financial planning, which directly impacts overall profitability.

Maintenance costs can vary based on factors such as machine complexity, usage levels, and the quality of materials used in the construction of the equipment. Regular servicing and timely repairs are necessary to ensure consistent performance and minimize downtime. Consequently, companies should enter into service agreements with reputable technicians or service providers specializing in such machines to maintain optimal performance levels. Furthermore, investing in training for staff who operate these machines can lead to lower maintenance costs over time by ensuring the equipment is operated correctly and safely.

Operational expenses include energy consumption, consumable materials, and workforce requirements. Given that energy storage machines are designed for efficiency, their energy consumption will markedly impact production costs. Buyers should carefully consider operational characteristics and evaluate energy savings when making purchasing decisions, which can lead to cost reductions across production runs. Additionally, the requirement for skilled labor may contribute to ongoing expenses, emphasizing the need for companies to evaluate their current workforce capabilities and train staff accordingly. Proper preparation in these areas ensures that investments in equipment yield maximum returns.

5. REGIONAL MARKET CONDITIONS AND THEIR INFLUENCE ON PRICING

The geographical location of a business can significantly affect the prices of energy storage nut projection welding machines. Regional market conditions, including competition, demand, and logistical considerations, ultimately shape the pricing landscape. Understanding these dynamics is crucial for prospective buyers seeking to make informed purchasing decisions.

In competitive markets where multiple manufacturers offer similar products, pricing can be more aggressive. Companies may find opportunities to leverage market competition to secure advantageous deals or allow for negotiation on prices. Conversely, in markets with limited options, prices may increase due to a lack of available competition, leading to more substantial overall costs for potential buyers.

Logistical aspects also come into play. The distance between manufacturing facilities and suppliers, as well as import tariffs and transportation costs, can impact pricing. For example, machines sourced from international manufacturers may incur additional fees that are not present when purchasing locally. Businesses must weigh these factors carefully when evaluating their purchasing strategies to mitigate unnecessary expenses.

6. FINANCING OPTIONS AND THEIR ROLE IN ACCESSIBILITY

Many businesses encounter challenges when attempting to purchase energy storage nut projection welding machines due to significant upfront costs. Financing options can play a pivotal role in facilitating access to these essential pieces of equipment, enabling companies to spread out payments over a more extended period. Various financing alternatives exist, including loans, leases, and leasing with an option to purchase.

Loans can be sourced via traditional banks or specialized lenders, allowing businesses to acquire equipment while repaying the borrowed amount over time. Banks may offer competitive interest rates, appealing to businesses aiming to minimize their financial burdens. However, thorough evaluation of loan terms and interest rates is critical for ensuring a manageable repayment plan.

Leasing arrangements provide another flexible avenue, allowing companies to use energy storage nut projection welding machines without committing to outright purchases. Lease agreements typically include options to acquire equipment at the contract’s conclusion, offering an attractive combination of access and flexibility. Businesses should evaluate whether leasing is more beneficial than purchasing, taking into account factors such as anticipated usage levels and budget constraints.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE AVERAGE PRICE RANGE FOR ENERGY STORAGE NUT PROJECTION WELDING MACHINES?

The average price range for energy storage nut projection welding machines generally lies between $10,000 and $100,000. However, this price range can fluctuate significantly depending on various factors such as machine specifications and brand reputation. Basic models equipped with standard features may fall at the lower end of the spectrum, while high-performance machines with advanced technology, greater functionality, and customization options can command prices on the higher end. Potential purchasers should take care to evaluate their operational requirements against features offered to achieve the best fit.

In addition to the base price, considerations regarding installation costs and necessary accessories or add-ons should be taken into account. Some suppliers may offer bundled packages that include training or support, which can influence overall expenses. Accordingly, prospective buyers are urged to obtain quotes from multiple manufacturers, assessing specifications, features, and warranties before making a final decision.

HOW CAN MAINTENANCE COSTS AFFECT THE LONG-TERM BUDGET FOR A WELDING MACHINE?

Maintenance costs can substantially influence the long-term budget for an energy storage nut projection welding machine, as they contribute significantly to ongoing operational expenses. Regular maintenance is essential for ensuring optimal performance and minimizing unplanned breakdowns that cause costly production interruptions. Skilled technicians must perform routine services, such as inspecting connections, replacing worn components, and calibrating weld parameters. The frequency and nature of these required services will determine the overall maintenance expenditure.

Fostering a proactive approach to maintenance can lead to substantial cost savings over time. Businesses can implement preventive maintenance protocols, including regular schedules for inspections and care, reducing the likelihood of unforeseen repairs. Staff training is also crucial to ensure equipped operators handle the machinery competently, lowering the chances of operational errors that could necessitate restabilizing the systems. Therefore, considering long-term maintenance implications ensures that businesses account for these costs accurately within their overall budgeting frameworks.

WHAT ARE THE ADVANTAGES OF CHOOSING A BRANDED MACHINE?

Opting for a branded energy storage nut projection welding machine can confer numerous advantages, particularly concerning reliability and support. Established brand names often come with a legacy of quality and performance, fostering confidence in their technology and components. These brands typically invest in extensive research and development, frequently resulting in innovative features that enhance operational efficiency while minimizing downtime.

Moreover, purchasing from reputable brands generally ensures access to comprehensive customer support, spare parts, and service options, which can enhance operational longevity. The backing of an established company often provides users with peace of mind, as they can rely on a trusted manufacturer for assistance in optimizing machine performance and troubleshooting any issues that arise. Overall, selecting branded machines contributes to a more robust return on investment through reduced maintenance needs, enhanced performance capabilities, and reliable ongoing support.

THE EXPENSES ASSOCIATED WITH ACQUIRING ENERGY STORAGE NUT PROJECTION WELDING MACHINES CAN VARY SIGNIFICANTLY DEPENDING ON MULTIPLE FACTORS. KEY CONSIDERATIONS INCLUDE MACHINE SPECIFICATIONS, BRAND REPUTATION, CUSTOMIZATION REQUIREMENTS, LONG-TERM MAINTENANCE, OPERATIONAL COSTS, REGIONAL MARKET CONDITIONS, AND FINANCING OPTIONS. FIRST, INVESTORS MUST THOROUGHLY ANALYZE THE NECESSITY OF THE MACHINE WITHIN THEIR OPERATIONS AND EVALUATE THE PRICE AGAINST THESE FACTORS. THEN, ARRANGING FOR A BUDGET THAT ACQUIRES THE RIGHT BALANCE BETWEEN THE INITIAL INVESTMENT AND LONG-LASTING OPERATIONAL EFFICIENCY IS PARAMOUNT. BY TAKING INTO ACCOUNT EACH ASPECT DISCUSSED, BUSINESSES CAN ENSURE THAT THEY MAKE INFORMED DECISIONS REGARDING THEIR ACQUISITION, ULTIMATELY LEADING TO MAXIMIZED RETURN ON INVESTMENT. THE INFLUENCE OF MACHINE COST ON OPERATIONAL SUCCESS FURTHER UNDERLINES THE IMPORTANCE OF DILIGENT PLANNING AND STRATEGIC PURCHASING TO ACHIEVE SUSTAINABLE GROWTH OVER TIME.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-much-does-the-energy-storage-nut-projection-welding-machine-cost/