1. Solar pipe insulation costs can vary widely based on numerous factors, including materials used, thickness, location, and the service provider. 2. On average, consumers can expect to spend between $1.50 to $3.50 per linear foot for standard insulation materials. 3. High-performance insulation options, such as aerogel or fiberglass, can reach prices upwards of $6 per linear foot. 4. Installation costs may also range from $50 to $100 per hour depending on the complexity of the pipes and local labor rates. Elaborately, it is essential to consider that opting for higher-quality materials often leads to improved energy efficiency, which can offset initial expenditures over time through reduced energy bills.

1. IMPORTANCE OF SOLAR PIPE INSULATION

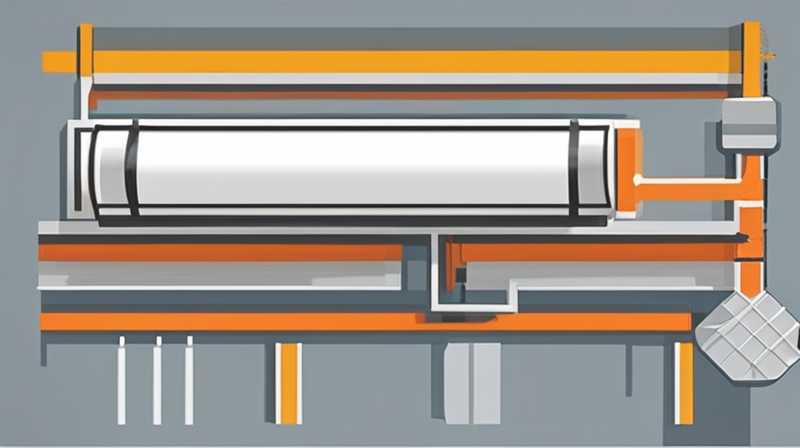

The significance of using insulation for solar pipes cannot be overstated. In solar thermal systems, insulated pipes are crucial for maintaining the temperature of the fluid being transferred from solar collectors to storage tanks or heating systems. The primary function of insulation is to minimize heat loss during transportation, ensuring that the energy harnessed from the sun is utilized as efficiently as possible. This is not just about energy conservation; it also correlates directly with the economic viability of solar systems. Exceptional insulation keeps the system operating effectively, which is fundamental in maximizing the return on investment for solar energy installations.

Heat retention can significantly impact overall system efficiency. If insulation is inadequate or improperly installed, heat loss becomes inevitable, especially during transit across longer distances. Consequently, this heat loss results in an increased demand from backup heating sources, counteracting the benefits acquired from utilizing solar energy. Therefore, investing in high-quality solar pipe insulation is not only an upfront expense but also a vital long-term strategy to ensure that solar investments yield favorable returns in the long run. Furthermore, in warmer climates or during peak sun hours, having adequate insulation can create an optimal balance, allowing systems to function smoothly without overheating and reducing wear on components.

2. FACTORS INFLUENCING COST

Purchasing solar pipe insulation involves several considerations that contribute to its overall pricing. Understanding these factors can empower consumers to make informed decisions that align with their budget while still achieving desired efficiency levels.

Material Type plays a critical role in establishing costs. Traditional insulation materials, such as fiberglass, are generally less expensive but may not offer the same level of efficiency as advanced alternatives. Aerogel insulation, for instance, is one of the most efficient materials available, delivering superior thermal performance while minimizing bulk, but its production costs remain high. This leads to a marked price differentiation and presents a challenging decision for consumers weighing cost against performance.

The thickness of insulation also impacts pricing. Typically, thicker insulation provides better thermal resistance. However, it can also increase the cost per linear foot. During planning stages, assessing the specific needs of a solar system (e.g., expected temperature fluctuations) is essential to select an appropriate thickness that meets efficacy requirements without overspending.

Labor costs can substantially add to the total expense. Installation can be intricate, especially in retrofits or systems with complex piping layouts. Hence, prices can fluctuate significantly depending on geographic location, local market rates, and the complexity of the installation itself. In urban areas with high living costs, labor fees can surge compared to rural environments. Thus, consumers should gather multiple quotes from certified professionals to obtain an accurate picture of overall installation expenses.

3. TYPICAL MATERIALS USED

Identifying the standard materials used for solar pipe insulation is integral to understanding the cost structure. Each material has unique properties that affect both performance and pricing, making it crucial for consumers to choose wisely based on their specific requirements.

The most popular choice is fiberglass insulation. Known for its affordability and widespread availability, fiberglass plays a vital role in numerous solar installations. Its effectiveness in minimizing heat loss makes it a favorable option for many homeowners and commercial projects. However, while fiberglass insulation has shown reliable performance over time, it may not achieve the high thermal performance of newer materials, which could warrant consideration of alternate options.

Another noteworthy material is polyurethane foam, which boasts enhanced thermal properties compared to fiberglass. This foam creates a tight seal around pipes, effectively preventing airflow that could lead to heat loss. However, polyurethane insulation typically carries a higher price point, challenging individuals to weigh its effectiveness against competing options. When engaging in discussions regarding installation values, many advocates for polyurethane emphasize the long-term benefits such as reductions in energy bills, further justifying the costs.

Mineral wool insulation has surged in popularity due to its fire-resistant qualities and acoustic insulation properties. While it is typically used in commercial projects, it is also finding its way into residential solar installations. The pricing for mineral wool varies, often remaining competitive with fiberglass and providing additional assurances (such as fire resistance) that justify potential cost increases.

4. INSTALLATION CONSIDERATIONS

While the choice of insulation material significantly impacts overall costs, the installation process also plays a pivotal role. Several factors must be accounted for to ensure that insulation not only fits adequately but also provides the necessary thermal protection.

Professional installation is often recommended. Though some may contemplate undertaking DIY projects to save money, improper installation can lead to inefficiencies and further expenses down the line. Skilled technicians can assess the intricacies of individual installations, ensuring that all piping is properly insulated to prevent any heat loss. Furthermore, professionals can guide customers regarding optimum thickness and material choices, often resulting in better outcomes as well.

The complexity of the existing plumbing system also affects installation time and costs. Retrofits or adjustments to existing infrastructure may require additional labor or modifications that can elevate overall expenses. Simple, straightforward installations tend to yield lower labor costs, while more convoluted systems may introduce complications that necessitate extended installation schedules. This consideration highlights the importance of detailed planning and consultation during the planning stage to obtain an accurate cost estimate.

Lastly, regional variations in codes and requirements can also impact costs. Regulations regarding the type of insulating materials or installation methods can introduce additional variables, compelling consumers to adapt their choices based on geographical statutory compliance. Researching local ordinances or consulting with specialists familiar with regional requirements can assist in navigating this complex landscape effectively.

5. LONG-TERM ENERGY SAVINGS

One of the compelling reasons to invest in quality solar pipe insulation is the potential for significant energy savings over time. A properly insulated system minimizes heat loss, which can lead to a reduced reliance on supplementary heating sources. This translates into lower energy bills while elevating the return on investment associated with a solar energy system.

Calculating energy savings can be complex, but many estimates suggest that effective insulation can improve overall efficiency by as much as 30 percent. This stat emphasizes that the initial investment in higher-quality insulation can pay dividends in reduced operational costs. By maintaining optimal fluid temperatures, systems can function within ideal parameters, which ultimately stretches the longevity of system components and minimizes repair costs over time.

Moreover, as utility costs continue to rise, the impact of energy savings becomes more pronounced. The longer an insulated system operates efficiently, the greater the cumulative savings achieved. Therefore, the choice to invest in superior insulation materials is not merely a transient expenditure; it can be viewed as a long-term strategy for financial prudence. Installing the appropriate insulating materials today can mitigate concerns regarding escalating energy costs tomorrow.

6. ENVIRONMENTAL AND POLICY CONSIDERATIONS

Beyond the immediate cost implications, one should take into account environmental considerations tied to solar pipe insulation. The decision to insulate is intrinsically linked to sustainability; when higher efficiency is achieved, it directly contributes to energy conservation.

Eco-friendly insulation options, such as cellulose or sheep’s wool, can serve dual purposes. These materials not only offer effective thermal properties but are also biodegradable and made from renewable resources, thus reducing the overall carbon footprint associated with energy consumption. Choosing sustainable insulation alternatives aligns with many consumers’ values while yielding substantial benefits in terms of energy efficiency.

Moreover, government policies may also play a role in influencing insulation choices and costs. Many regions offer incentives, tax credits, or rebates for utilizing energy-efficient products, including advanced insulating materials. By taking advantage of such programs, consumers can significantly lower respective costs, making the investment more appealing. It is vital for potential buyers to remain informed about these offerings, as they can drastically influence the financial landscape around insulation choices.

SOLAR PIPE INSULATION FAQs

WHAT FACTORS AFFECT SOLAR PIPE INSULATION COSTS?

Several aspects play a role in determining the costs associated with solar pipe insulation. Key factors include material type, thickness, labor expenses, and complexity of the installation. Material choice significantly influences pricing; traditional materials like fiberglass tend to be more affordable compared to high-performance options like aerogel. Thickness is another consideration, as thicker insulation often yields better thermal resistance but increases costs. Additionally, labor charges can vary greatly across regions, influenced by local market rates or the intricacies involved in specific installations. Ultimately, consumers should engage multiple quotes and weigh the above factors when assessing the total expenditure associated with solar pipe insulation.

HOW CAN I CALCULATE POTENTIAL ENERGY SAVINGS FROM INSULATED PIPES?

To determine potential energy savings from insulated pipes, consider several variables. Firstly, calculate the expected heat loss without insulation, factoring in the length of pipes, fluid temperatures, and outdoor temperatures. Existing data or simulation models may offer estimates of energy loss in uninsulated systems. Once established, compare these figures against calculations reflecting expected heat loss with insulation—often found in product specifications or energy efficiency literature. These figures can then provide insight into energy-saving potentials, typically expressed in percentage terms, contributing to a transparent view of how insulation impacts overall efficiency and ultimately influences energy bills.

DOES INSULATING PIPES HELP REDUCE CARBON FOOTPRINT?

Yes, insulating pipes can significantly contribute to reducing one’s overall carbon footprint. Effective insulation minimizes heat loss during fluid transit, leading to reduced energy consumption from heating sources. This decreased energy demand coincides with lower greenhouse gas emissions, especially if conventional fossil fuels power backup systems. Additionally, choosing eco-friendly insulation materials can further diminish environmental impacts. Carbon footprints associated with insulation installation can be considerably offset through these energy-saving practices, creating a harmonious balance between resource conservation and sustainability efforts over time.

Equipping oneself with knowledge regarding solar pipe insulation costs and their implications proves essential for any individual considering an investment in solar energy systems. Making decisions rooted in a comprehensive understanding of material options, labor expenses, and long-term savings positions consumers to optimize their investments. The intersection of performance and price creates a dynamic where quality cannot be sacrificed for cost; thus, ensuring selections align with desired outcomes is paramount. Policymaking and eco-consciousness further enhance purchasing decisions, advocating for practices that benefit both wallets and the planet. Such proactive engagement guarantees that consumers emerge informed, poised to navigate the landscape of solar energy efficiently while minimizing their environmental impact, substantially elevating the effective utility of renewable energy efforts.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-much-does-solar-pipe-insulation-cost/