1. Solar incubation equipment typically ranges in cost from $1,500 to $10,000 depending on the size, features, and brand, 2. The type of incubation system, whether manual or automated, also affects pricing significantly, 3. Additional expenses may include installation, maintenance, and energy costs associated with operation, 4. Choosing a reputable manufacturer can provide better warranties and long-term reliability, 5. Understanding specific needs for operation, including egg capacity and climate control, is essential in determining the right equipment. The investment in solar incubation equipment reflects considerations of sustainability and self-sufficiency.

1. UNDERSTANDING SOLAR INCUBATION EQUIPMENT

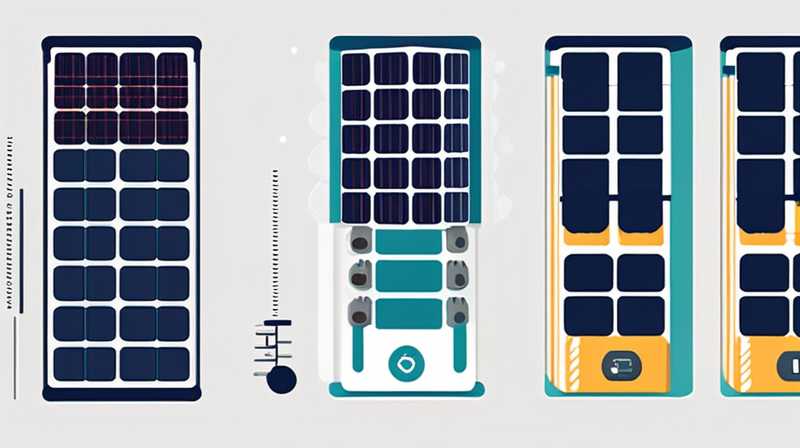

Solar incubation represents a transformative approach to traditional hatching methods, utilizing renewable energy sources to optimize the incubation process for avian eggs. This technology caters to anyone from hobbyists engaged in small-scale farming to larger agricultural enterprises seeking sustainable solutions. The energy captured from solar panels ensures that the hatching environment is not only reliable but also minimizes reliance on expensive electricity from conventional sources.

Exploring the cost structure of solar incubation equipment involves examining various factors affecting pricing, such as the system’s capacity, feature set, and technology employed. While basic models may be affordable, advanced systems integrating high-quality materials and sophisticated climate control systems can command far greater prices. Understanding these distinctions helps potential buyers align their investment with their long-term operational goals.

2. FACTORS INFLUENCING COSTS

The price of solar incubation apparatus is not solely determined by the visible aspects of the equipment; rather, it involves a complex matrix of factors. These include technical specifications, energy efficiency ratings, and the overall design of the incubator. The integration of features such as automatic turning mechanisms, humidity control, and temperature management systems can substantially affect the total expenditure.

Another crucial aspect is the size and capacity of the equipment. Smaller incubators designed for limited usage tend to be lower in cost, while models intended for commercial use can be significantly pricier. The purchase decision should consider present and future production needs, ensuring the selected equipment can accommodate growing demands without requiring immediate replacement or additional investment.

Also, the choice between manual and automated systems can greatly impact budget considerations. Automated systems, featuring intricate controls, typically represent a higher initial cost but offer increased efficiency and less labor overhead over time, making them more attractive for larger scale operations.

3. INSTALLATION AND OPERATION EXPENSES

Investing in solar incubation equipment encompasses more than just the purchase price; associated expenses such as installation and operational costs must also be considered. Installation often requires professional assistance to ensure that the solar panels are optimally placed, enhancing energy capture for maximum efficiency. Improper installation can lead to inefficiencies, potentially escalating long-term costs associated with energy consumption.

When evaluating the operational costs of solar incubators, one must consider maintenance of the equipment as well as the ongoing expenses related to energy. Regular checks and servicing of solar panels and incubators can prevent monetary loss due to breakdowns or inefficiencies, reinforcing the initial investment. Moreover, while solar power reduces reliance on traditional energy sources, variability in sunlight can necessitate backup systems or energy storage solutions, which could introduce additional expenditure.

4. LONG-TERM BENEFITS OF INVESTMENT

Investing in solar incubation technology yields myriad long-term advantages. These systems inherently promote sustainability by reducing the environmental impact associated with traditional energy use. By opting for renewable energy, users contribute positively to ecological preservation while benefiting from lower operational costs.

Financial savings are paramount when evaluating the return on investment. While the initial outlay may be substantial, the long-term reduction in energy bills and possible incentives or rebates for utilizing solar power can create significant savings over time. Consequently, operations can enjoy increased profitability without compromising their commitment to sustainable practices.

Furthermore, utilizing solar technology often enhances self-sufficiency, particularly in regions where electricity access is unreliable. By autonomizing the incubation process, farmers can alleviate risk while ensuring a more stable production cycle. This control over production directly translates into higher yields and, ultimately, more robust economic stability.

5. COMPARING BRANDS AND MODELS

Market research plays a pivotal role in discerning which brand or model of solar incubator is suitable for specific needs. Recognizing the differences in warranties, material quality, and customer support creates an informed decision-making process. Many manufacturers offer various models tailored to different farming needs—from small-scale operations to larger agricultural enterprises—allowing purchasers to match their selection with operational requirements.

Brands often provide comprehensive specifications detailing the energy consumption, hatching rates, user reviews, and testimonials from other customers, showcasing long-term reliability and efficiency. Investigating these factors before purchase allows for sound investments that deliver value over time. Additionally, investigating the reputation of manufacturers via online forums or social media can enrich one’s understanding of which products possess superior functionality and customer satisfaction.

6. MAKING AN INFORMED DECISION

Ultimately, acquiring solar incubation equipment is a profound decision that can impact both productivity and financial sustainability. Prospective buyers should conduct thorough research, comparing models, understanding operational needs, and estimating both initial and ongoing costs effectively. This due diligence ensures that the investment not only meets immediate requirements but aligns with broader farming strategies and values.

In summary, clarity about personal and business objectives informs the selection process. An understanding of solar tech integration encourages exploration of available options, leading to a purchase that aligns with broader visions of sustainability and agricultural innovation.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE MAIN ADVANTAGES OF SOLAR INCUBATION EQUIPMENT?

Solar incubation equipment provides numerous advantages, including the utilization of renewable energy sources that significantly reduce energy costs over time. By harnessing sunlight, these systems promote sustainability, allowing users to operate independently from conventional electricity grids. Furthermore, solar incubators are designed to maintain a stable and controlled environment, which enhances hatching rates and improves the overall quality of poultry production. Many models include features that permit automated control of temperature and humidity, ensuring optimal conditions for egg incubation. This not only simplifies the hatching process but also minimizes human error, providing greater reliability. Moreover, initial investments in solar incubation technology may qualify for government rebates, grants, or incentives, further decreasing overall capital expenditure. Finally, choosing solar technology can contribute to a farm’s carbon footprint reduction, promoting ecological sustainability while simultaneously enhancing food security.

HOW DOES THE SIZE OF A SOLAR INCUBATOR AFFECT ITS COST?

The size of a solar incubator is intricately linked to its cost. Smaller incubators cater to hobbyists or small-scale farmers and are generally more affordable, allowing for accessible entry into poultry production. For instance, a compact solar-powered incubator might serve individual users effectively without overwhelming complexity or excess capacity. In contrast, larger models are more expensive due to their capacity to handle higher volumes of eggs, advanced technological features, and heightened construction quality. Commercial incubators often feature intricate climate control systems, automatic turning mechanisms, and enhanced insulation to ensure successful hatching for hundreds, if not thousands, of eggs. Therefore, while smaller machines can meet basic needs, larger solar incubators provide an efficient solution to scaling operations, allowing farms to increase productivity and profitability over time. Every prospective buyer should carefully evaluate their operational goals to determine the appropriate size and its associated costs, balancing initial investments with anticipated returns.

WHAT SHOULD POTENTIAL BUYERS LOOK FOR IN A SOLAR INCUBATOR?

When considering the acquisition of solar incubators, prospective buyers should prioritize several critical features to ensure their investment meets both functionality and durability requirements. It is essential to examine the equipment’s temperature and humidity control capabilities, as maintaining precise environmental conditions is crucial for successful hatching. Additionally, look for systems that incorporate automatic turning mechanisms, this feature not only streamlines operations but also guarantees consistent egg orientation. The capacity of the incubator directly corresponds to its ability to support the farmer’s current production goals, and buyers should consider future scalability as well. Evaluate the quality of materials used in construction, as durable materials enhance longevity and reliability, preventing premature wear or breakdown. Finally, potential purchasers must also consider customer reviews and brand reputation, assessing the experiences of previous users to ensure an informed decision and satisfaction with purchase choices.

In short, investing in solar incubation equipment necessitates careful consideration of the features, brands, and individual requirements to achieve optimal results. Understanding the cost structure will facilitate a seamless decision-making process, leading to enhanced agricultural productivity and the promotion of sustainable farming practices.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-much-does-solar-incubation-equipment-cost/