The cost of one meter of solar thermal insulation pipe varies significantly based on several factors. 1. Pricing generally ranges from $2 to $10 per meter, considering both material and type of insulation. 2. Initial investment, while seemingly high, is outweighed by long-term energy savings attributed to reduced heat loss. 3. Quality impacts the overall efficiency and durability, necessitating a balanced choice of price and performance. 4. Regional availability influences pricing, with localized suppliers potentially offering better rates due to lower shipping costs.

1. UNDERSTANDING SOLAR THERMAL INSULATION PIPES

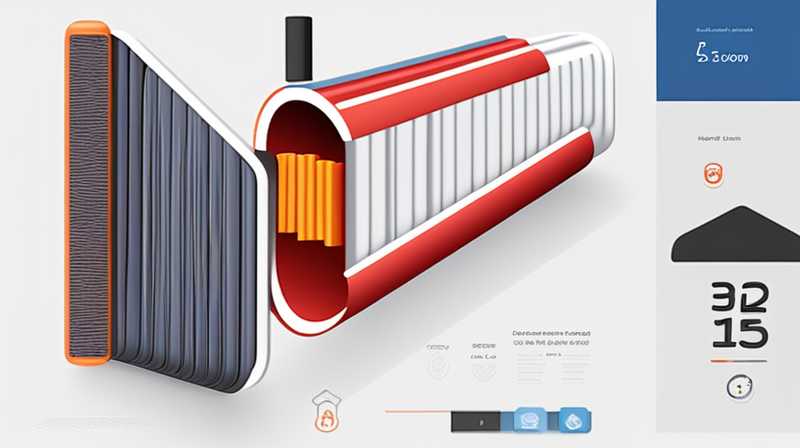

Solar thermal systems are vital for harnessing solar energy for heating applications, and the choice of insulation pipe plays a crucial role in this process. Insulation pipes are designed to minimize heat loss from the fluid that runs through them, maintaining higher temperatures and enhancing energy efficiency.

When selecting insulation pipes, it is important to understand the various insulation materials available. Foam, fiberglass, and mineral wool are common choices, each offering a unique set of thermal resistance properties, durability, and installation ease. The decision on which material to choose should be influenced by the specific needs of the solar thermal system, including temperature fluctuations, environmental conditions, and budgetary constraints. Additionally, understanding the thermal conductivity of insulation materials will enable better selection, ensuring that heat loss is minimized.

2. FACTORS INFLUENCING COSTS

The price of solar thermal insulation pipes is impacted by multiple factors that manufacturers and consumers should consider. Material quality, pipe diameter, and length are primary elements influencing pricing. High-performance materials exhibit better insulation characteristics, leading to higher initial costs, but they can result in greater long-term savings due to increased efficiency.

Furthermore, the installation method also affects the total cost. Various installation approaches may entail different labor intensities and time commitments. Simpler installations can lead to lower overall expenses, while more complex scenarios requiring specialized labor or additional components can significantly raise costs. Also, understanding local market dynamics dictates price variations. In some geographical areas, availability may drive pricing upward or downward, revealing the importance of choosing suppliers meticulously to optimize expenditure.

3. A COMPARISON OF INSULATION MATERIALS

The selection of insulation material ultimately determines both performance and costs. Foam insulation, for example, is lightweight and widely used due to its effective thermal resistance and ease of installation. Its closed-cell structure creates a barrier against moisture penetration, although it can be more expensive than other materials.

Fiberglass insulation presents another option, recognized for its affordability and excellent thermal properties. It is typically available in batts or rolls which can be easily cut to size, but it may require more careful handling to avoid skin irritation during installation. The thermal resistance value of fiberglass is considerable, making it suitable for a range of applications where performance is paramount, despite its potential hazards.

Meanwhile, mineral wool insulation excels in fire resistance and sound attenuation, providing added benefits though slightly higher costs. Each material’s unique properties need thorough evaluation against project-specific requirements to make informed decisions that impact both immediate expenditure and future energy efficiency gain.

4. REGIONAL PRICE VARIATIONS

The geographical location can significantly influence solar thermal insulation pipe costs. Urban areas frequently present higher prices due to increased demand, associated overhead costs, and limited supply. Conversely, rural regions may showcase lower pricing due to fewer distribution points, resulting in less competition and, subsequently, lower prices.

Local climate conditions also heavily influence the insulation needed. Areas requiring higher performance insulation due to extreme temperatures may face different pricing models compared to regions with milder climates. Consumers need to consider local suppliers carefully, as they may provide insights into regional pricing trends and product performance tailored to specific environmental needs.

5. CALCULATING TOTAL EXPENSES

When determining the financial implications of installing solar thermal insulation pipes, several factors must be included in the calculation. Material costs, labor costs for installation, and any supplementary components necessary for a complete system must all be factored in to establish an accurate budget.

Moreover, potential returns on investments, achievable energy savings over time, and possible government incentives for installing energy-efficient systems should also be factored into this equation. Therefore, clients must conduct a comprehensive financial analysis that encompasses upfront costs and long-term savings, ensuring that each spending decision is aligned with the overarching goal of achieving energy efficiency.

6. CONTRACTOR AND SUPPLIER SELECTIVITY

Choosing the right contractor or supplier plays a critical role in both performance and cost-effectiveness of solar thermal insulation installation. Prospective buyers should seek out established professionals with experience in solar thermal systems and extensive knowledge of insulation pipe trends.

Contracts must detail material specifications, warranties, and project timelines, ensuring that all parties have clear expectations. By obtaining multiple quotes, buyers can discern reasonable pricing levels and assess the value offered against competitors. This vetting process ensures not only that the selected option is economically sound but also that the quality of work meets satisfactory standards.

7. ADDITIONAL COST CONSIDERATIONS

In addition to the basic costs associated with piping materials and installation, there are ancillary expenses that can arise during a solar thermal system implementation. Permitting, site preparation, or subsequent system maintenance could add unexpectedly to the overall expenditure.

Permitting processes can vary greatly in cost and duration depending on local regulation frameworks. Site preparation can necessitate additional labor or materials if adjustments in design choices occur at later stages of a project. Finally, annual maintenance expenses must be considered to continue enjoying the efficiency and benefits of the installed insulation pipes.

8. QUALITY AND LONGEVITY

The relationship between quality and long-term endurance cannot be overstated, particularly with solar thermal insulation. Customers should seek pipes with robust warranties reflective of their expected lifespan and performance guarantees. Higher-quality materials tend to resist environmental factors such as UV degradation, moisture, and mechanical wear superiorly, thereby extending their functional life and reducing long-term costs.

Owners of solar thermal systems equipped with quality insulation will find themselves reaping benefits for many years, enjoying efficient energy use and lower operational costs. Although the initial investment may appear significant, the payback period diminishes as savings accumulate over the lifespan of the installation, thereby illustrating the advantageous long-term financial implications of choosing high-quality systems.

FAQs

WHAT IS THE AVERAGE COST PER METER OF SOLAR THERMAL INSULATION PIPE?

The typical price of solar thermal insulation pipe varies considerably, influenced by factors such as material choice, insulation type, and location. Generally, prices can range from $2 to $10 per meter. The specific type of pipe material selected has a direct impact on these costs, with high-efficiency options commanding higher prices but offering better thermal performance and sustainability. Buyers need to carefully evaluate costs against energy savings over the expected lifespan of the insulation to make a financially sound decision.

WHAT FACTORS AFFECT THE INSTALLATION COST OF SOLAR THERMAL INSULATION PIPES?

Installation costs for solar thermal insulation pipes are influenced by labor rates in the region, installation complexity, and the types of accessories or fittings required. Regions with higher labor demands typically observe increased prices, while installations that necessitate considerable modifications or specialized labor also fall on the higher end of the spectrum. Additionally, selecting high-quality materials may increase upfront expenses but yield significant returns in the form of energy efficiency and reduced maintenance needs.

HOW DOES INSULATION QUALITY IMPACT ENERGY SAVINGS?

Higher insulation quality ensures lower heat loss, enabling systems to operate at optimal efficiency. Different insulation materials offer various thermal resistance capabilities, significantly influencing overall energy consumption and operational costs. Superior insulation minimizes the amount of energy required to maintain desired system temperatures, thereby enhancing performance efficiency and reliability in energy savings. Proper selection safeguards the investments made into solar thermal systems while maximizing their operational longevity.

FINAL THOUGHTS

In evaluating the costs associated with solar thermal insulation pipes, numerous aspects merit attention. Various factors from regionally influenced pricing, material quality, installation demands, and potential energy savings must weave together into a comprehensive financial analysis. Making well-informed decisions regarding insulation purchases not only aids immediate financial outlays but also optimizes long-term performance, contributing to overall sustainability goals. Thus, customers should seek to understand detailed variables impacting their choices and to work with reputable suppliers and contractors to ensure that their investments yield fruitful outcomes. This careful financial and strategic approach will ultimately lead to enhanced energy efficiency, reduced operational costs, and a positive environmental impact over the long run. By understanding the intricacies involved in solar thermal insulation pipe costs, individuals and organizations can make empowered choices that align with their financial and energy-related objectives.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-much-does-one-meter-of-solar-thermal-insulation-pipe-cost/