1. Cost Factors for Flat Panel Solar Pipe Fittings Typically Ranges Between $100 to $500, Depending on Material Quality, Size, and Application, Local Installation Expenses Can Significantly Impact Overall Pricing, Custom or Specialty Fittings May Encur Higherguided Costs. In-depth Analysis of Key Pricing Components Reveals Quality and Performance Substantially Influence Long-Term Value.

The rising adoption of solar energy has created a significant demand for components that facilitate the efficient functioning of solar systems. Among these components, flat panel solar pipe fittings play a crucial role in connecting various parts of the solar thermal system. When assessing the expenses related to flat panel solar pipe fittings, it is vital to consider several factors that contribute to the overall pricing. This investigation will delve into the nuanced aspects affecting costs, which include but are not limited to material selection, size, application, installation fees, and regional market conditions.

MATERIAL SELECTION

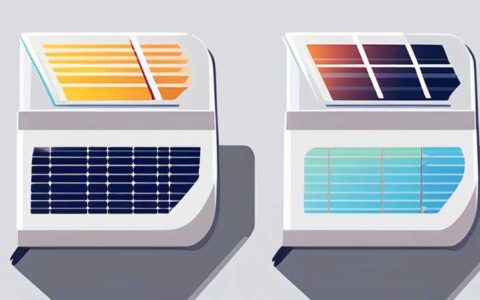

The choice of materials constituting flat panel solar pipe fittings profoundly influences their overall cost. Common materials include copper, stainless steel, and plastic. The selection of copper fittings, for instance, often emerges as the premium option due to its superior thermal conductivity, durability, and resistance to corrosion. However, it comes at a higher price point compared to alternatives. On the other hand, plastic fittings, while more economical, usually lack the longevity or performance efficiency of metal fittings.

Furthermore, the treatment of materials also comes into play. For example, fittings that undergo additional treatment to enhance corrosion resistance or improve their structural integrity involve an increase in overall expenses. On analysis, those opting for lower-cost fittings must weigh the potential long-term ramifications of frequent replacements or decreased efficiency. Investment in higher-quality materials may entail a steeper initial outlay but often results in more durable installations with extended lifespans.

SIZE AND APPLICATION

Another pivotal factor in determining the pricing of flat panel solar pipe fittings is their size and intended application. Standard fittings generally exhibit lower costs due to mass production efficiencies; however, custom fittings or those made to accommodate specific systems tend to command premium pricing. Notably, the sizes can vary significantly based on installation requirements; larger dimensions frequently escalate material costs and processing expenses.

Moreover, the intended application of these fittings significantly affects their cost. For instance, fittings designed for high-pressure systems will necessitate a robust build and may require specialized manufacturing processes, thereby increasing their cost. Similarly, fittings that operate under extreme environmental conditions can incur additional expenses associated with material selection and engineering standards. Careful consideration must be given to selecting fittings that align with the specific requirements of the solar system and the surrounding environment, as inadequacies in this area can lead to reduced system effectiveness.

LOCAL INSTALLATION EXPENSES

The expenses associated with the local installation of flat panel solar pipe fittings can vary substantially across different regions. Installation fees might encompass labor, equipment, and additional materials needed during the process. Regions with higher labor costs will reflect increased expenses in the installation phase, thereby contributing to the overall price of the solar heating system. Furthermore, local building codes and regulations can necessitate further expenditures, as compliance may require additional fittings or modifications.

Hiring a certified professional offers advantages in ensuring quality installation. While this might lead to an initial outlay, proper installation generally results in enhanced system performance and longevity, therefore counterbalancing higher upfront costs. The recognition of local market trends and availability of certified workers can guide consumers in making educated decisions regarding installation.

REGIONAL MARKET CONDITIONS AND SUPPLY CHAIN INFLUENCES

Another aspect influencing the cost of flat panel solar pipe fittings is regional market conditions. Geographic variances can exhibit significant fluctuations in both availability and demand, ultimately impacting pricing. For example, areas with strong solar initiatives may experience increased market competition, resulting in lower costs for fittings and installation services.

Additionally, global supply chain disruptions have proven to be crucial in shaping product availability and pricing. Given the fluctuating nature of raw material costs, prices can rise or decline based on external variables. In recent years, the impact of logistic challenges, trade tariffs, and geopolitical tensions has created unpredictable conditions for suppliers of solar components, including pipe fittings.

Consequently, consumers must stay informed about market trends and conditions that can influence pricing, ensuring they engage suppliers that provide competitive and fair rates. Collaborating with local providers committed to transparency in pricing and sourcing can be beneficial in gaining insights into market fluctuations and achieving greater value in procurement.

RECENT TECHNOLOGICAL DEVELOPMENTS

Emerging technological advancements have steadily started to refine the production and design of flat panel solar pipe fittings. These innovations could lead to reductions in costs while simultaneously enhancing performance efficiency. For instance, the introduction of advanced manufacturing techniques such as 3D printing is beginning to revolutionize the production process, allowing for cost-effective customization of fittings while decreasing material waste.

Conversely, despite technological progress, investments in research and development remain pertinent to ensuring that fittings meet safety and performance standards. Suppliers dedicated to adopting and integrating new technologies into their production processes can not only optimize operational costs but also provide long-term value to consumers, creating products that better suit evolving solar energy systems.

REGULATORY ENVIRONMENT AND INCENTIVES

Government policies and incentives can substantially influence the costs associated with flat panel solar pipe fittings. As sustainability initiatives gain traction, many governments offer subsidies or incentives for solar projects. Such assistance often extends to the costs associated with equipment, materials, and installation. Homeowners and businesses that leverage these programs effectively can significantly offset initial investment costs, therefore allowing for a smoother transition to solar energy.

Moreover, regulations addressing material standards and installation practices may impose additional costs on manufacturers and consumers. Remaining compliant with local regulations necessitates careful research and planning, as deviations can lead to legal hurdles and potential fines. By ensuring adherence to existing regulations, solar system owners can enhance the reliability and longevity of their investments.

MARKET RESEARCH AND COMPARISON SHOPPING

It is incumbent upon consumers to engage in thorough market research prior to finalizing their purchases. Regularly analyzing market fluctuations and pricing trends can shed light on fair expectations for fittings. Transparent quotes that detail all aspects of pricing can help buyers evaluate product offerings comprehensively.

During research, comparing multiple providers can also yield insight into product variety, corresponding prices, and company reputations. Consumer reviews and professional ratings often reveal growth in product effectiveness and value, which are critical when choosing among suppliers. Implementing these techniques can enhance decision-making processes and secure greater value for investments in flat panel solar pipe fittings.

BUYING IN BULK AND LONG-TERM INVESTMENTS

Procuring flat panel solar pipe fittings in bulk can lead to tangible savings. Many suppliers offer significant discounts for larger quantitative purchases, drastically reducing the overall expense per unit. This can be especially beneficial for contractors or businesses undertaking extensive solar projects needing numerous fittings.

Emphasizing long-term value also encourages homeowners and businesses to appreciate the cost as an investment rather than merely an expense. By opting for durable fittings, the likelihood of repairs and replacements diminishes, ultimately resulting in a more cost-effective solution over time. Therefore, individuals need to weigh the initial outlay in the context of potential long-term operational savings.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE COMMON MATERIALS USED FOR FLAT PANEL SOLAR PIPE FITTINGS?

Flat panel solar pipe fittings are primarily made from materials such as copper, stainless steel, and plastic. Copper is favored for its excellent thermal conductivity and durability. While stainless steel provides good strength, plastic fittings are often lighter and less costly. The choice of material impacts not only the cost but also the efficiency and reliability of the solar system. When selecting fittings, considering the specific thermal and environmental needs of the installation is crucial, as this will dictate material compatibility and longevity. Additionally, investing in quality materials typically leads to better performance and reduced maintenance over time.

HOW CAN I REDUCE THE COST OF INSTALLING SOLAR PIPE FITTINGS?

To mitigate the expenses associated with installing solar pipe fittings, consumers can explore several strategies. One option involves researching multiple contractors to secure competitive quotes. Many professionals offer tiered pricing based on service packages or have ongoing promotional discounts. Additionally, consider purchasing fitting materials in bulk, as many suppliers provide lower prices per item for larger quantities. Moreover, being aware of available government incentives and subsidies can help offset costs. Engaging in meticulous planning can ensure efficient use of resources, which may avoid unnecessary expenditures. Lastly, DIY installations can also lower costs; however, this requires adequate knowledge and skills to ensure safety and compliance with local codes.

WHAT FACTORS INFLUENCE THE LONG-TERM VALUE OF SOLAR PIPE FITTINGS?

Several elements play a role in determining the long-term value of flat panel solar pipe fittings. First, the quality of materials strongly correlates with durability and service life. Higher-quality materials tend to withstand wear and tear better, reducing the frequency of replacements. Next, the installation practices carried out by professionals are paramount; proper installation can enhance system performance and minimize failure risks over time. Additionally, compliance with local building regulations protects against legal liabilities and may enhance resale value in the future. Finally, continued market research and investment in technological advancements can ensure solar systems maintain optimal performance levels, justifying the initial expenses made.

Timely investment, research, and planning will allow consumers to leverage the benefits associated with flat panel solar pipe fittings, ensuring peace of mind and enhanced system efficiency in the long term. The analysis of costs should encompass a comprehensive perspective, factoring in pricing variations and intrinsic value derived from appropriate fitting selection. By making informed decisions, users can successfully navigate the complexities of costs and ultimately enhance the performance and sustainability of solar thermal systems.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-much-does-flat-panel-solar-pipe-fittings-cost/